10

USA

Check the plate, read the pressure and verify that the description of the nozzle installed corresponds to the one supplied

by the manufacturer.

Connection with natural gas

The connection pressure for natural gas is 1.74 kPa.

THIS APPLIANCE IS EQUIPPED FOR NATURAL (PROPANE) (LP) GAS

This appliance is equipped with orifices sized for operation with natural (PROPANE) (LP) gas.

For conversion to LP (propane) (natural) gas see instruction plate on the appliance.

Orifices necessary for LP (propane) (natural) conversion are provided .*

Check the plate, read the pressure and verify that the description of the nozzle installed corresponds to the one supplied

by the manufacturer.

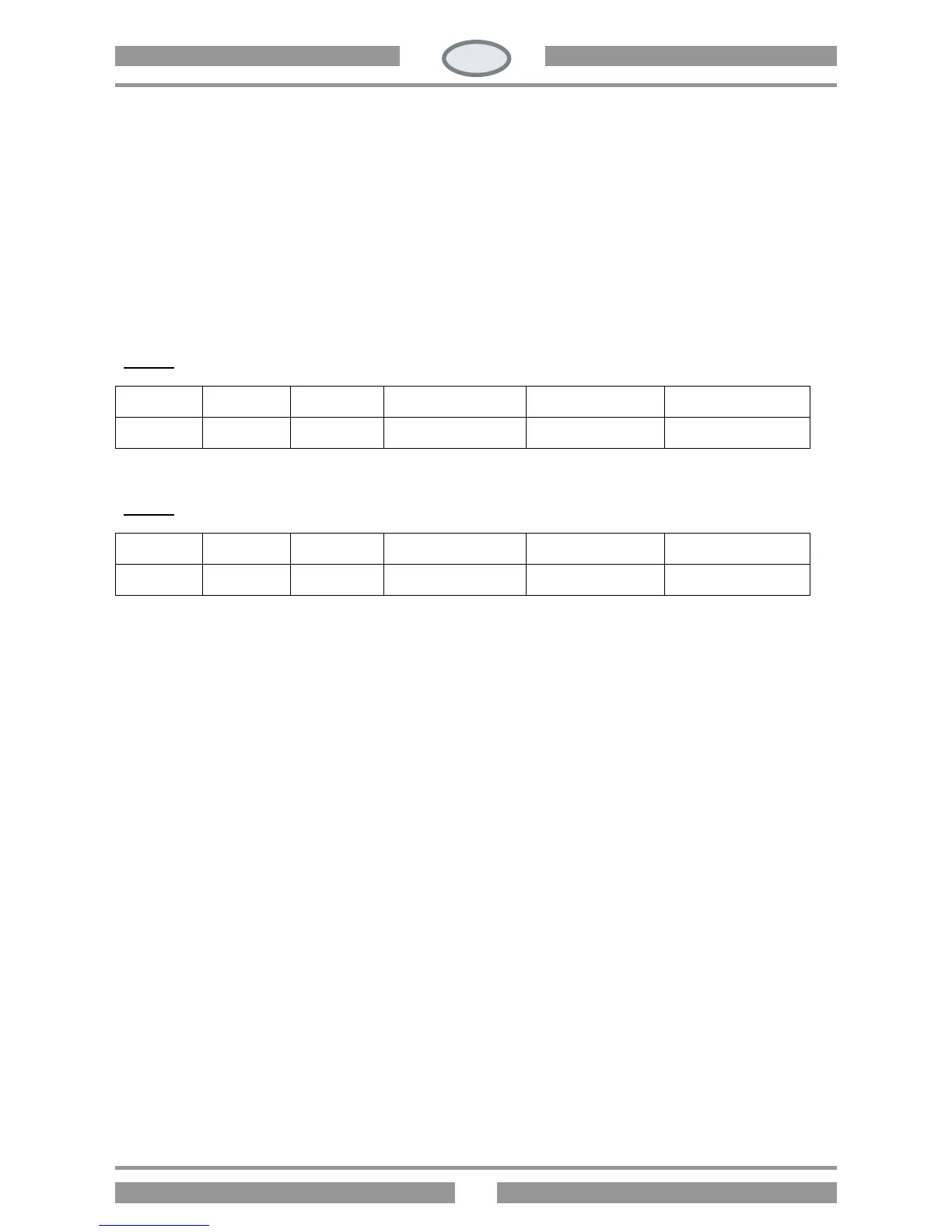

“BURNERS” TECHNICAL DATA TABLE

CP-94G

Nominal

input

Reduced

input

Primary air

setting

Main burner injector Pilot burner injector By-pass screw

47600 Btu/h

14 kW

16400 Btu/h

4.8 kW

GAS A: open

GAS E: open

GAS A: 3.50mm (Ø)

GAS E: 2.05mm(Ø)

GAS A: 0.62 mm (Ø)

GAS E: 0.30 mm (Ø)

GAS A: 1.25 mm(Ø)*

GAS E: 1.25 mm(Ø)**

* Unscrewed for about one turn + 1/2 turn.

** Screwed fully down.

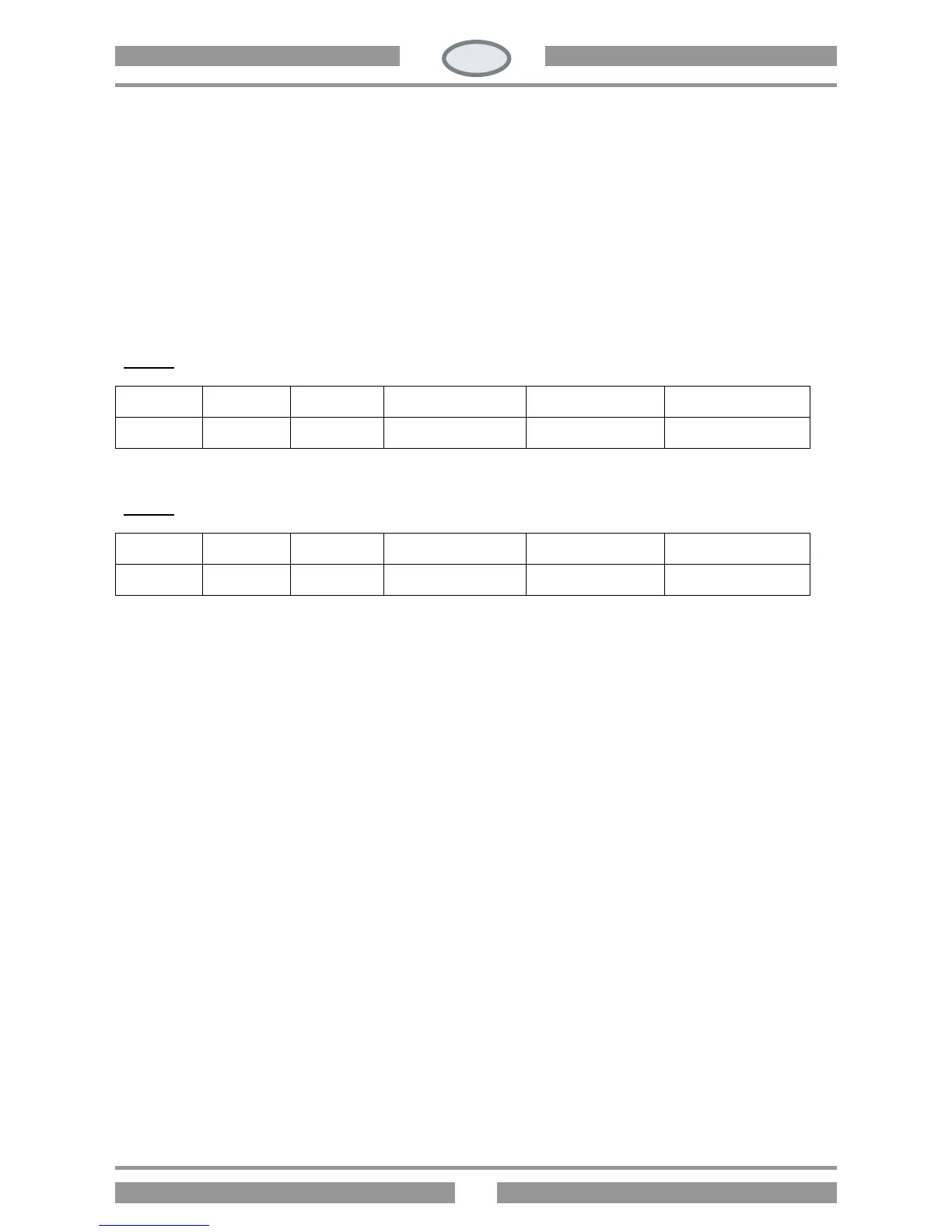

CP-98G

Nominal

input

Reduced

input

Primary air

setting

Main burner injector Pilot burner injector By-pass screw

95200 Btu/h

28 kW

32800 Btu/h

9.6 kW

GAS A: open

GAS E: open

GAS A: 3.50mm (Ø)

GAS E: 2.05mm(Ø)

GAS A: 0.62 mm (Ø)

GAS E: 0.30 mm (Ø)

GAS A: 1.25 mm(Ø)*

GAS E: 1.25 mm(Ø)**

* Unscrewed for about one turn + 1/2 turn.

** Screwed fully down.

NOTE: GAS A = Natural gas

(pressure at the outlet of the regulator)

= 10 mbar (4 inch water)

NOTE: GAS E = Propan gas

(pressure at the outlet of the regulator)

= 24.9 mbar (10 inch water)

RULES FOR CONVERTING AND INSTALLING FOR OTHER TYPES OF GAS

Our appliances are tested and regulated with liquid gas (see data plate).

The conversion or adaptation to another type of gas must be carried out by a specialised technician. The nozzles for the

various types of gas are supplied in a packet and are marked in hundredths of mm (see “burners” technical data table).

SUBSTITUTING THE NOZZLE IN THE MAIN BURNER

• Remove the front fixing screws from the panel, remove the start-up cable from the piezoelectric ignition device

• Using a suitable spanner, unscrew the nozzle and substitute it with the right one (see the technical data table).

SUBSTITUTING THE NOZZLE IN THE PILOT BURNER

The flame of the pilot burner has fixed air.

The only operation necessary is the substitution of the nozzle according to the type of gas.

It is therefore necessary to unscrew the screws as specified in the previous point; with a suitable spanner unscrew the

fitting and substitute the nozzle with a suitable one. With the right nozzle, the flame must lap the thermocouple.

Important!

After having carried out the conversion to another type of gas, it is necessary to update the data plate, indicating the

type of gas for which the appliance has been converted.

CHECKING FUNCTIONING

• The appliance contains the instructions necessary for use.

• Check the appliances for gas leaks.

Loading...

Loading...