LOAD SENSOR

Page 9

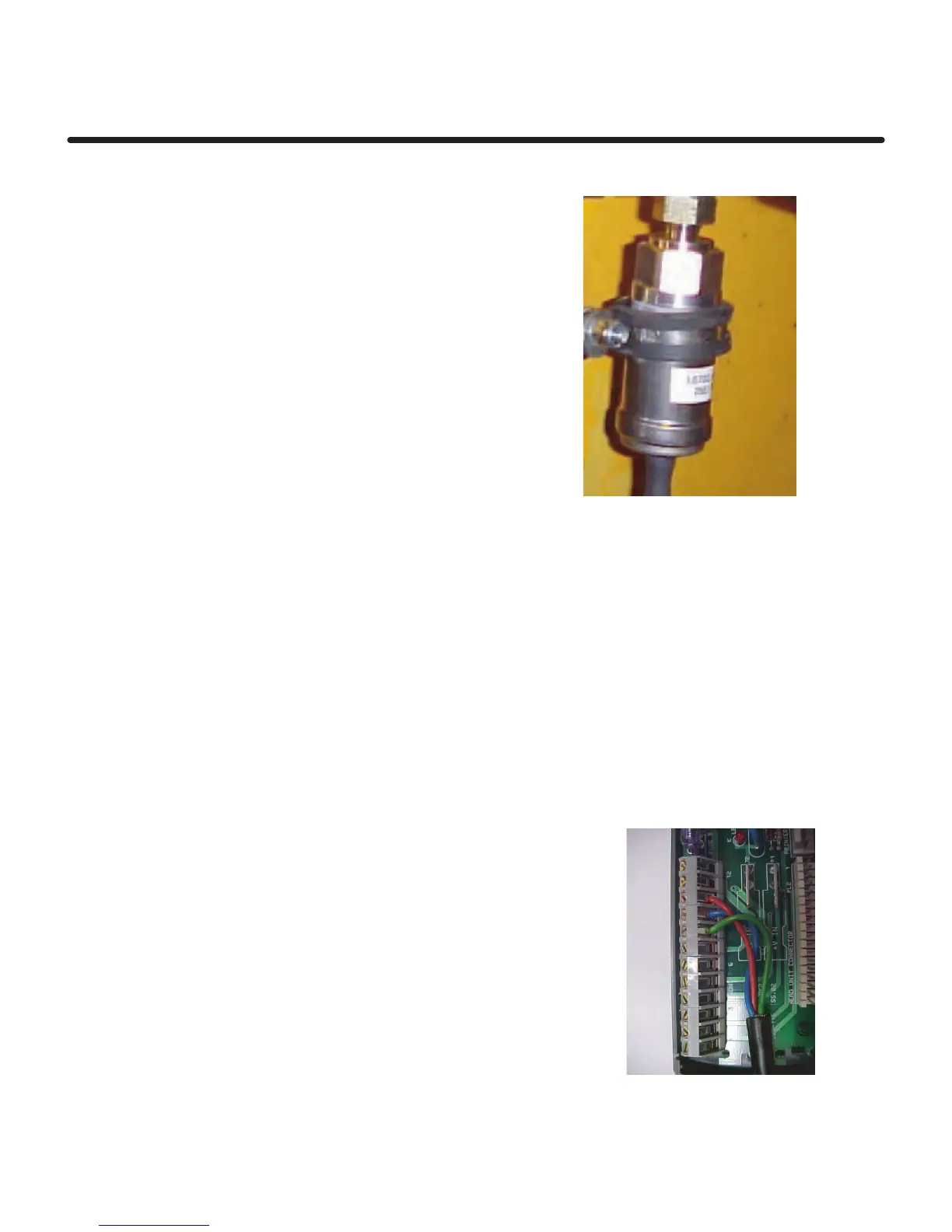

Mounting the Load Sensor

1. Connect the hydraulic hose to the tee

fitting and route the hose towards the

sensor mounting location. Connect to

the load sensor and mount the sensor

in a well protected area, one that can

also be accessed for servicing.

NOTE:Mount the pressure sensor in a well

protected area, in an upside down

position as shown. This helps prevent

air bubbles from hitting the load

sensor diaphragm.

Bleeding the Load Sensor

This can be done whenever convenient during the installation procedure.

Lift the boom so that it is a few inches off the floor. Have an assistant loosen

the hydraulic fitting to allow any air to escape. You may have to bleed the

sensor more than once. It is recommended that the machine is worked for

5 to 10 minutes and then the bleeding procedure be repeated.

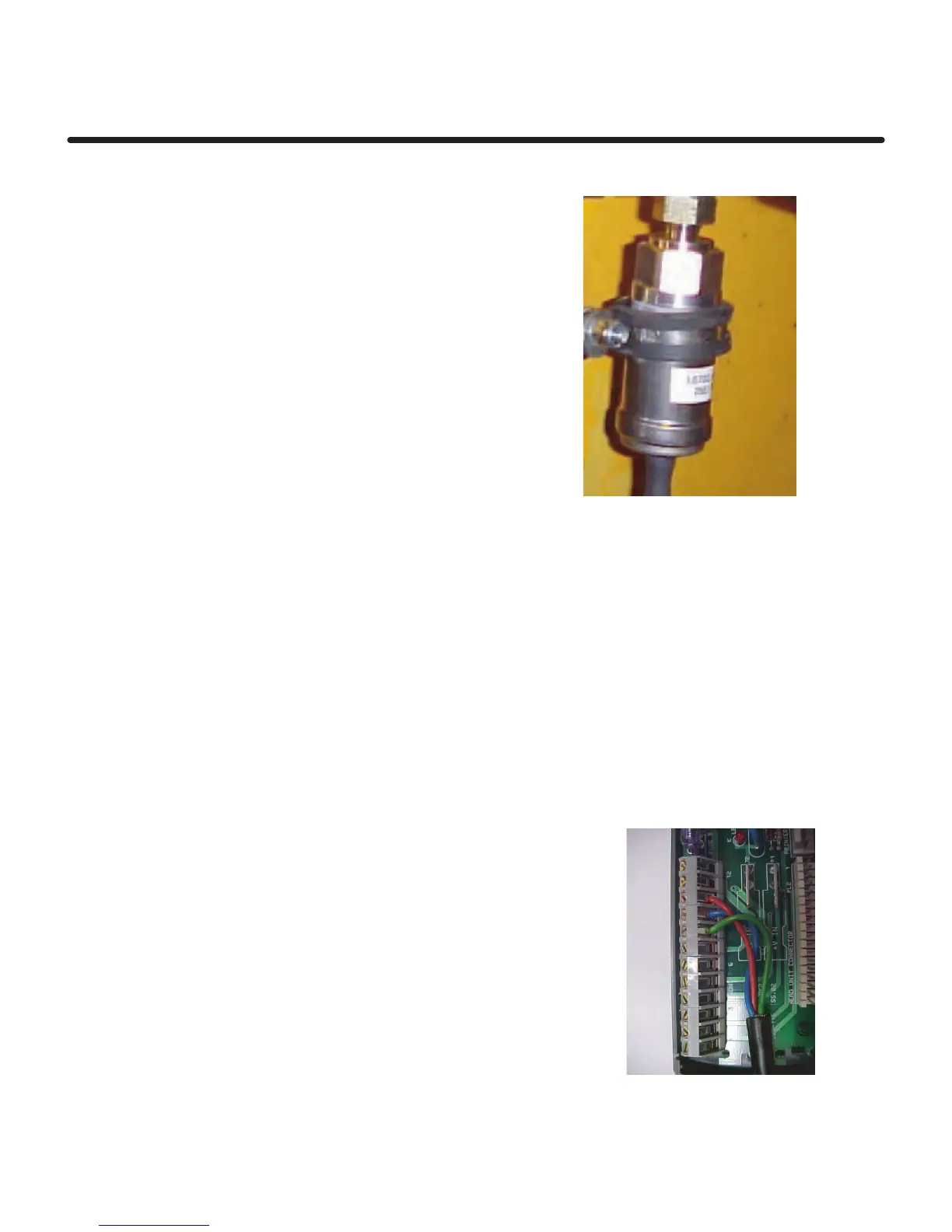

Load Sensor Connection

2. Connect the extension cable to the weatherpack connector on the sensor lead and

route back to the Junction box. Cable tie wires securely to existing

hydraulic lines or hoses.

Avoid coiling excess cable. Leave a small amount of slack at the sensor for movement.

If the sensor cable is long enough to reach the J-Box then make a short pig tail with

the extension cable rather than cutting the sensor cable.

3. Connect the wires according to the label

on the Junction box lid.

Color Function Terminal #

Red +V 10

Blue oV 9

Green Signal 8

NOTE: There is no provision for strain relief on these connections. Its recommended that

sensor cables are cable tied back very near the junction box.

12

11

10

9

8

7

6

5

4

3

2

1

Loading...

Loading...