LOAD SENSOR

Page 6

Load Sensor

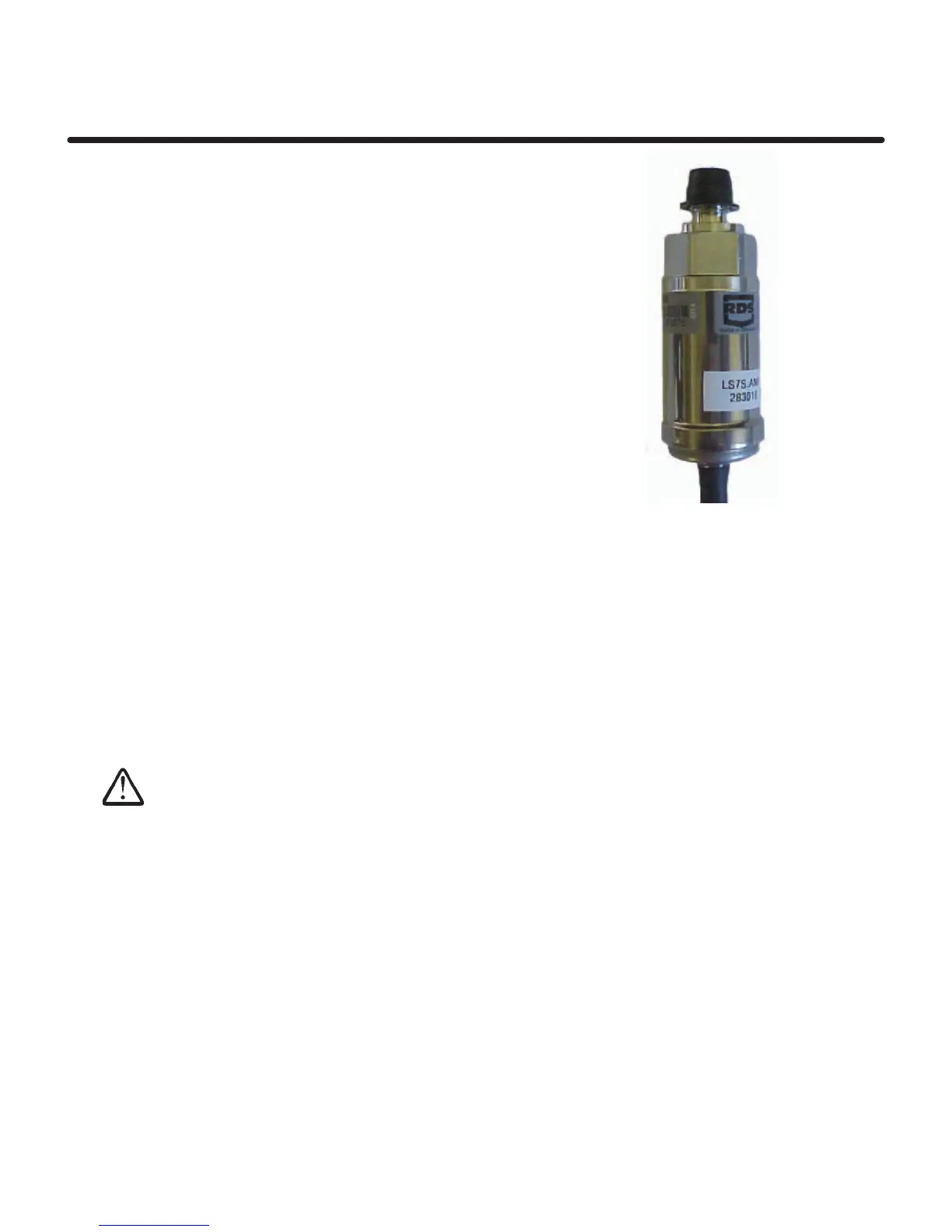

The load sensor (fig. 2a) is connected by

a flexible hose into the pressure side of

the hydraulic circuit, using a tee fitting.

Depending on the machine, you may be

using a threaded tee piece, SAE flange

coupling, or if there is no suitable

coupling you may have to drill and tap

into a suitable point.

The machine is normally specified when

ordering a Weighlog kit so the correct

adaptor should be in the kit.

Where to tee in

Identify the lift hose on one of the main lift cylinders. Trace the lines back toward

the valve block , (at some point the lines from the other cylinder will join into a

single line). Identify a suitable coupling which allows enough room to be split and

the tee adaptor to be inserted, or in the absence of a suitable coupling, a point

which can be drilled and tapped. The tee in points could be anywhere between

the lift cylinder and the valve block but ideally should be as close as possible

to the lift cylinder.

1.

Make sure that the bucket is down on the ground and all pressure is released

from the hydraulic system, before loosening any hydraulic fitting! Always

loosen or open the cap on the hydraulic tank to help release any pressure.

2. Thoroughly clean around the tee in point before splitting, to prevent the ingress

of dirt into the system.

3. Make sure that the tee in point will allow the hose to reach the load sensor

mounting location. The load sensor needs to be mounted up under the machine

where it is protected.

Loading...

Loading...