LOAD SENSOR

Page 7

Installing the Load Sensor

The load sensor contains a snubber to protect if from shock loading. This consists

of a diagonally drilled hole 0.3 mm in diameter. It is possible to block this hole with

debris causing the sensor to malfunction.

If a load sensor is installed on a machine where there may be particles of debris

in the oil, or the installer is unable to ensure the components being installed are

kept clean, it is advisable to pre fill the flexible hose with clean oil.

When a load sensor is installed the first supply of oil also contains all the debris and

contamination in the lines feeding it. Once this line has filled there is no flow of

oil and consequently no risk of contamination arriving at the sensor. In order to avoid

this problem we recommend that if you suspect there is the possibility of contamination

in the oil then please ensure the hose feeding the sensor is pre filled with clean oil.

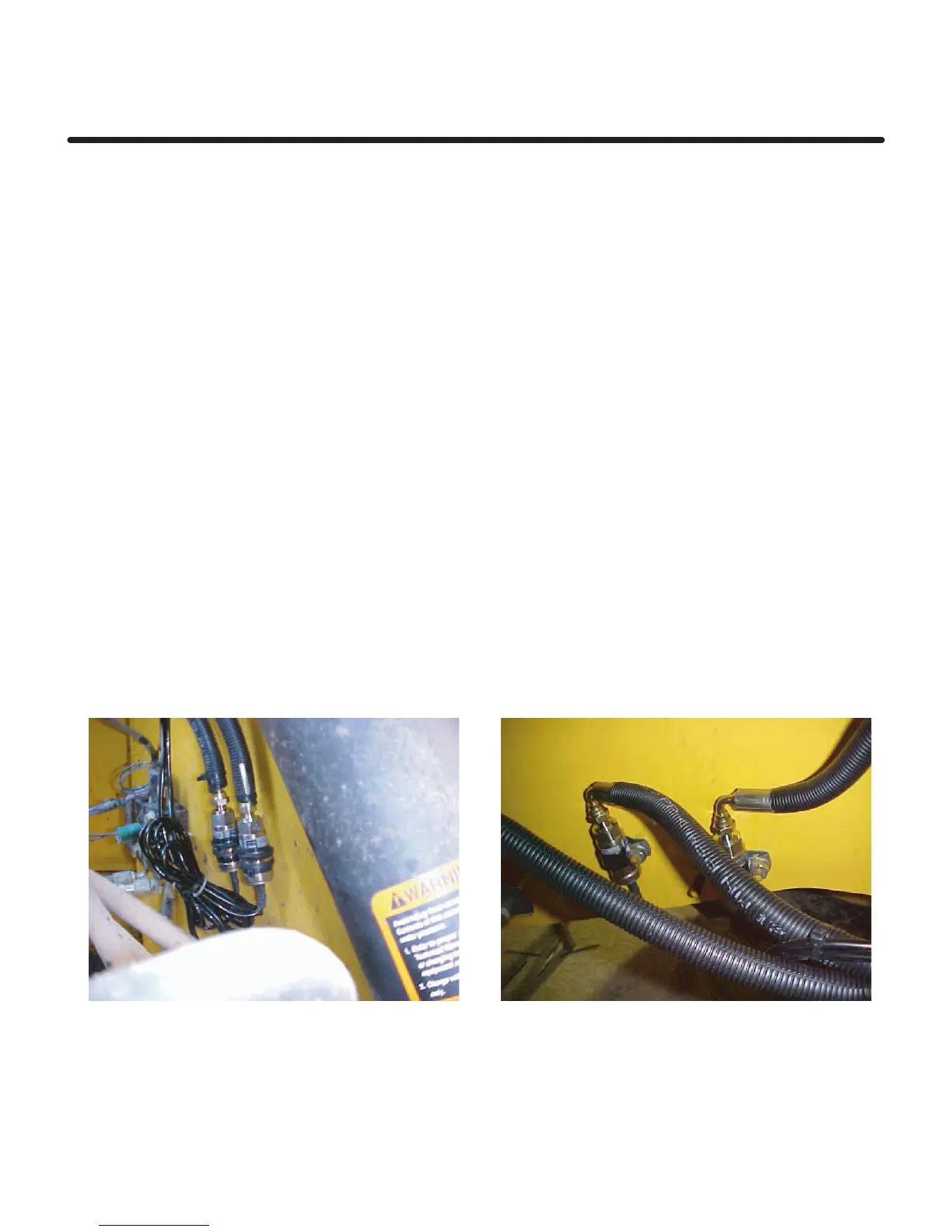

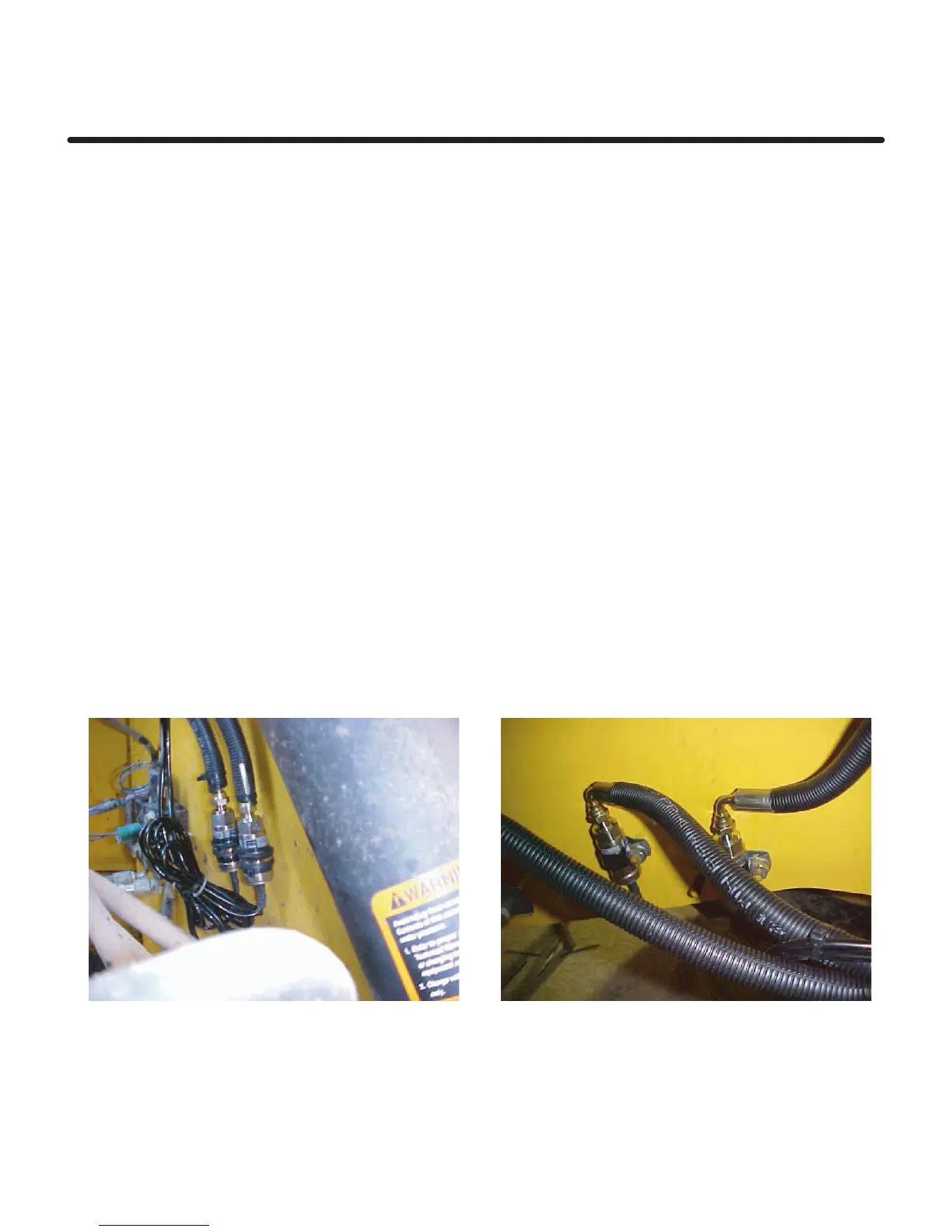

Please note that the pressure sensor must be mounted with the hose connection at the

top, so that all the air can bleed out of the sensor. If you do not mount the sensor as

illustrated below premature failure may occur due to air being trapped inside.

Loading...

Loading...