LYCOMING OPERATOR’S MANUAL SECTION 1

IO-320 SERIES DESCRIPTION

This relief valve regulates the engine oil pressure by allowing excessive oil to return to the sump, while

the balance of the pressure oil is fed to the main oil gallery in the right half of the crankcase. During its

travel through this main gallery, the oil is distributed by means of separate drilled passages to the main

bearings of the crankshaft. Separate passages from the rear main bearings supply pressure oil to both

crankshaft idler gears. Angular holes are drilled through the main bearings to the rod journals. Oil from the

main oil gallery also flows to the cam and valve gear passages, and is then conducted through branch

passages to the hydraulic tappets and camshaft bearings. Oil enters the tappets through indexing holes and

travels out through the hollow push rods to the valve mechanism, lubricating the valve rocker bearings and

valve stems. Residual oil from the bearings, accessory drives and the rocker boxes is returned by gravity to

the sump, where after passing through a screen it is again circulated through the engine. Pressure build up

within the crankcase is held to a minimum by means of a breather located on the accessory housing.

In addition, model IO-320-C1A incorporates oil jets in the crankcase. The oil jets furnish an oil spray to

provide internal cooling for the pistons.

Priming System – Provision for a primer system is provided on all engines employing a carburetor. Fuel

injected engines do not require a priming system.

Ignition System – Two magnetos furnish dual ignition. Consult Table 1 for model application. Bendix

magnetos are designed to permit periodic internal maintenance; Slick Electro magnetos are designed to

operate approximately 900 hours without internal maintenance.

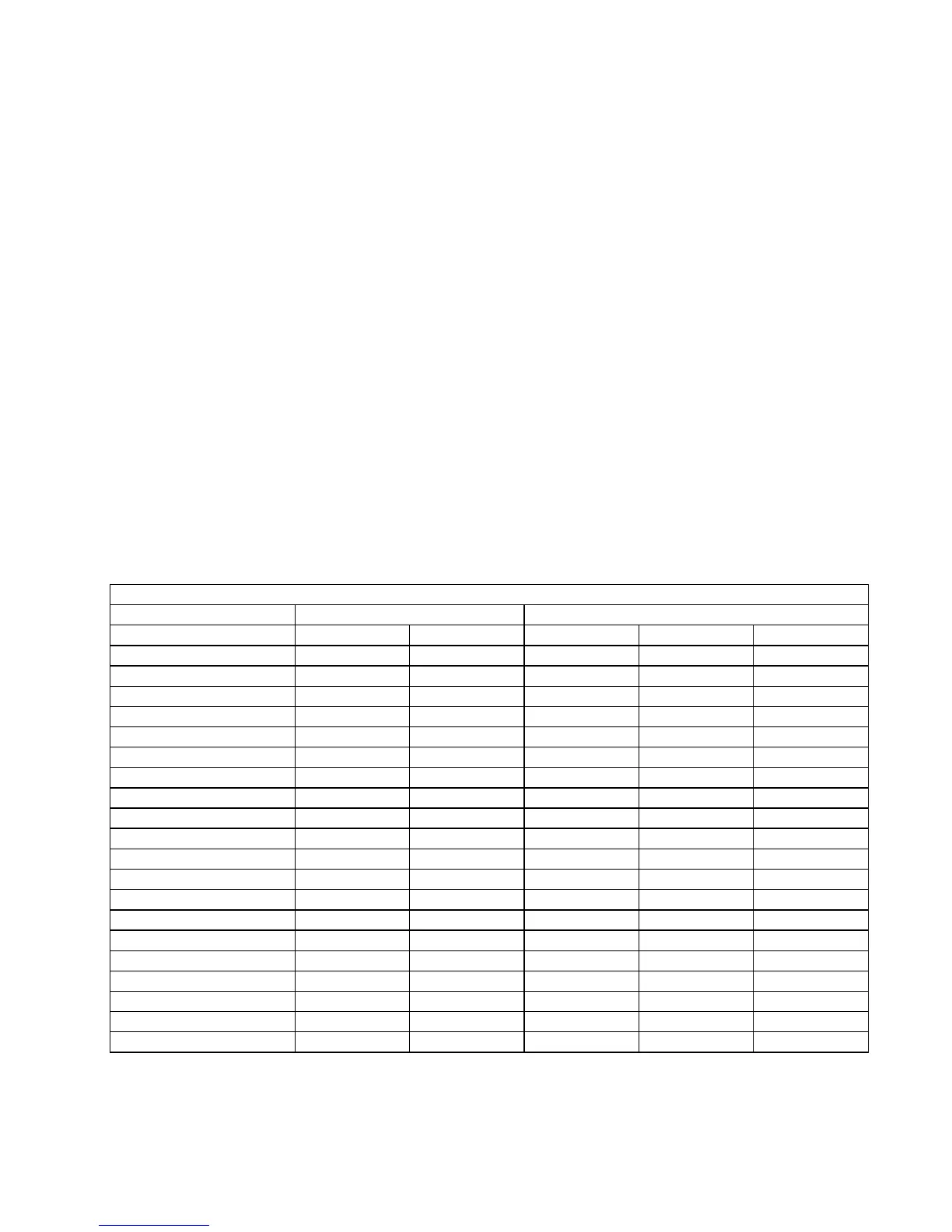

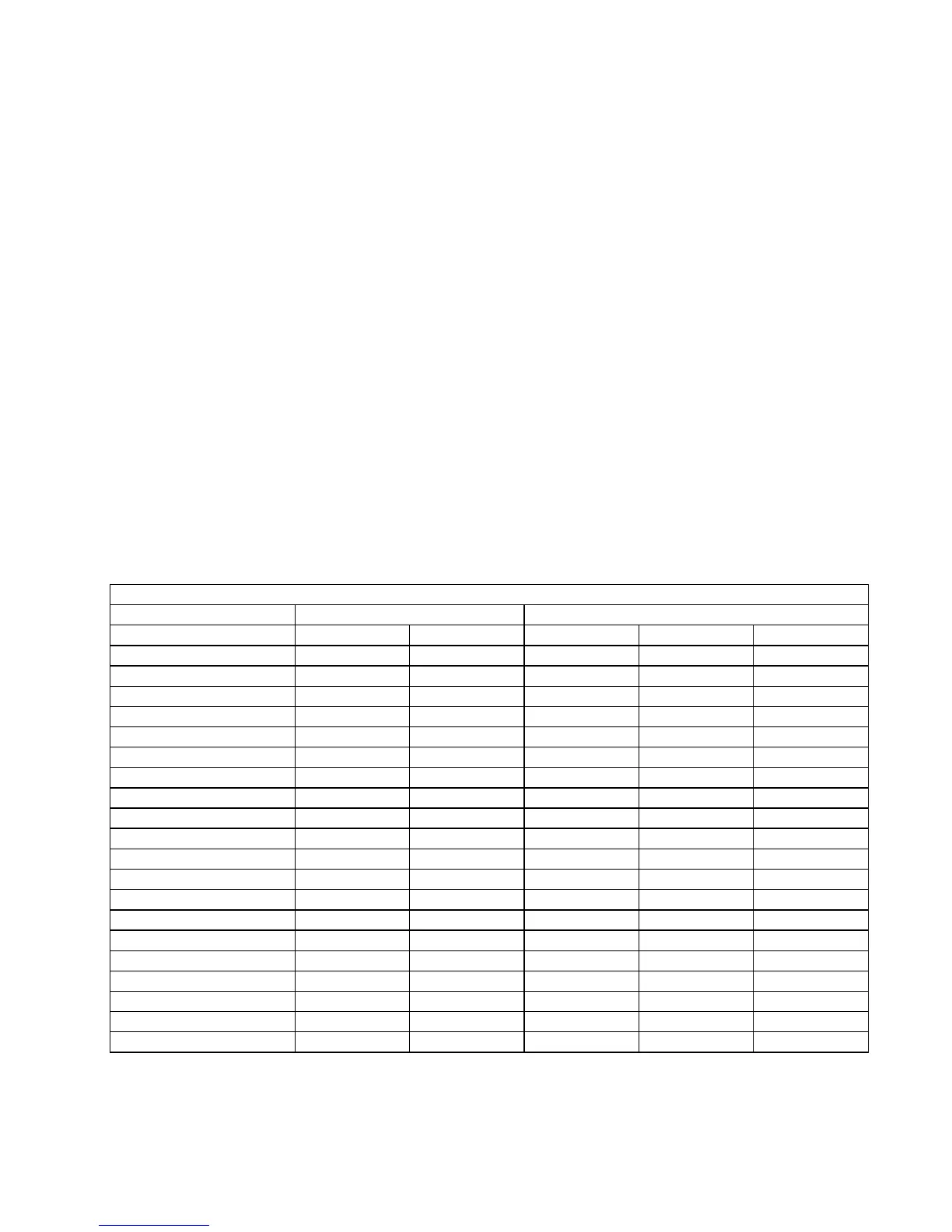

TABLE 1

MODEL APPLICATION

Model Magnetos Dimensions

IO-320 Left Right Height Width Length

-A1A, -A2A* S4LN-200 S4LN-204 19.22 32.24 33.59

-B1A, -B2A* S4LN-21 S4LN-20 19.22 32.24 33.59

-B1B S4LN-21 S4LN-20 19.22 32.24 33.59

-B1C S4LN-21 S4LN-20 19.22 32.24 32.09

-B1D S4LN-1208 S4LN-1209 19.22 32.24 32.09

-B1E 4251 4250 19.22 32.24 32.09

-C1A, -C1B S4LN-21 S4LN-21 19.22 32.24 33.59

-D1A, -D1B S4LN-1227 S4LN-1209 23.18 32.24 30.70

-D1C 4251 4250 23.19 32.24 29.05

-E1A, -E2A* S4LN-21 S4LN-20 23.18 32.24 29.56

-E1B 4051 4050 23.19 32.24 29.05

-E2B* 4051 4050 23.18 32.24 29.05

AIO-320

-A1A, -A2A* S4LN-1208 S4LN-1209 20.76 32.24 30.08

-A1B, -A2B* S4LN-1227 S4LN-1209 20.76 32.24 30.08

-B1B S4LN-1227 S4LN-1209 20.76 32.24 30.08

-C1B S4LN-1227 S4LN-1209 25.57 32.24 30.08

LIO-320

-B1A S4RN-21 S4RN-20 19.22 32.24 33.59

-C1A S4RN-21 S4RN-21 19.22 32.24 33.59

* - Fixed Pitch Propeller

1-3

Loading...

Loading...