(25) Before the oil sump is installed, safety wire the nuts that will be inside the oil sump

shown in Figure 91.

Figure 91

Safety Wire Nuts in Crankcase Oil Sump

24. Crankshaft Oil Seal Installation

NOTICE: If a solid-ring oil seal (Figure 48) is not already installed on the crankshaft a solid-ring

oil seal or split oil seal (Figure 47) can be installed after the crankcase is assembled.

A. Install the solid-ring oil seal in the crankcase as follows:

(1) Install a solid-ring oil seal on the crankshaft per “Solid-Ring Oil Seal Installation“.

(2) Use solvent and wipe excess grease from the crankshaft flange.

CAUTION DO NOT APPLY MEK SOLVENT TO THE CRANKSHAFT OIL

SEAL SINCE MEK CAN CAUSE THE SEAL TO DETERIORATE. BE

SURE THAT ALL TRACES OF CLEANING SOLVENT, OIL AND

SEALANT ARE REMOVED PRIOR TO INSTALLATION OF A NEW

CRANKSHAFT OIL SEAL.

(3) Use ethyl alcohol and disposable wipes to clean the outer surface of the seal and the

crankcase seal bore recess. Make sure nothing comes in contact with the cleaned surfaces.

CAUTION USE A BRUSH AND BUTYL RUBBER GLOVES WHEN APPLYING

SEALANT AND INSTALLING THE OIL SEAL (FIGURES 92 AND 93).

NOTICE: In the next step, do not get sealant on the crankshaft. If any sealant gets on the

crankshaft, use acetone to remove all traces of sealant.

If Pliobond

®

#20 or Pliobond

®

#25 is substituted for Dow Corning

®

737 Neutral

Cure Sealant, refer to the manufacturer’s instructions for application details and

cure time.

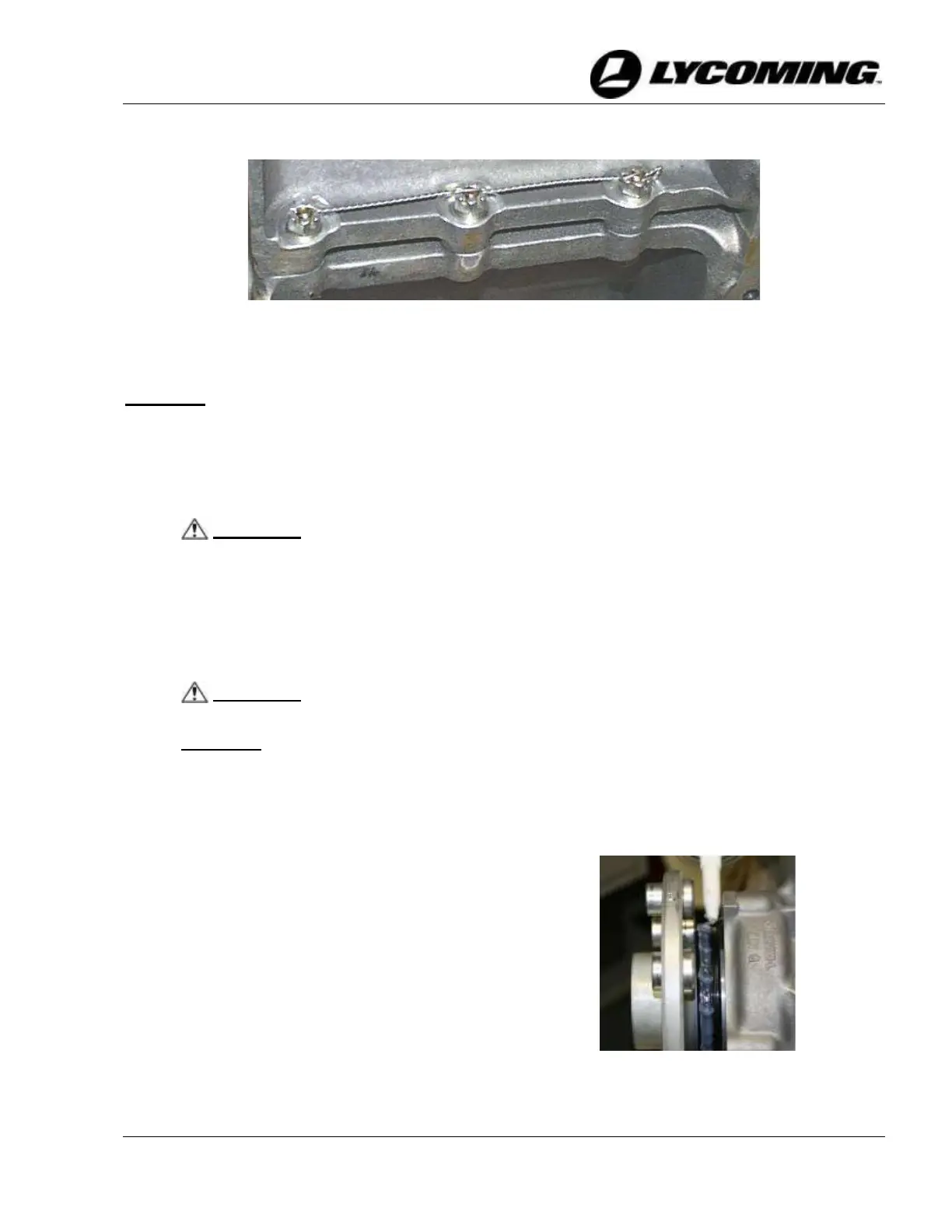

(4) Apply a liberal coating of Dow

Corning

®

737 Neutral Cure Sealant to

the outside diameter of the oil seal

(Figure 92) to allow the excess

sealant to squeeze out between the

crankcase and the oil seal when the

oil seal is installed.

(5) Press the solid-ring oil seal firmly

against the seat in the crankcase bore.

Apply pressure all around the seal

until it is firmly seated in the bore.

Loading...

Loading...