C-58

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

Whenever possible, the crankshaft should be removed

when new bearings are being installed in order to clean

the crankcase thoroughly. All bearing surface must be

free of grit and burrs.

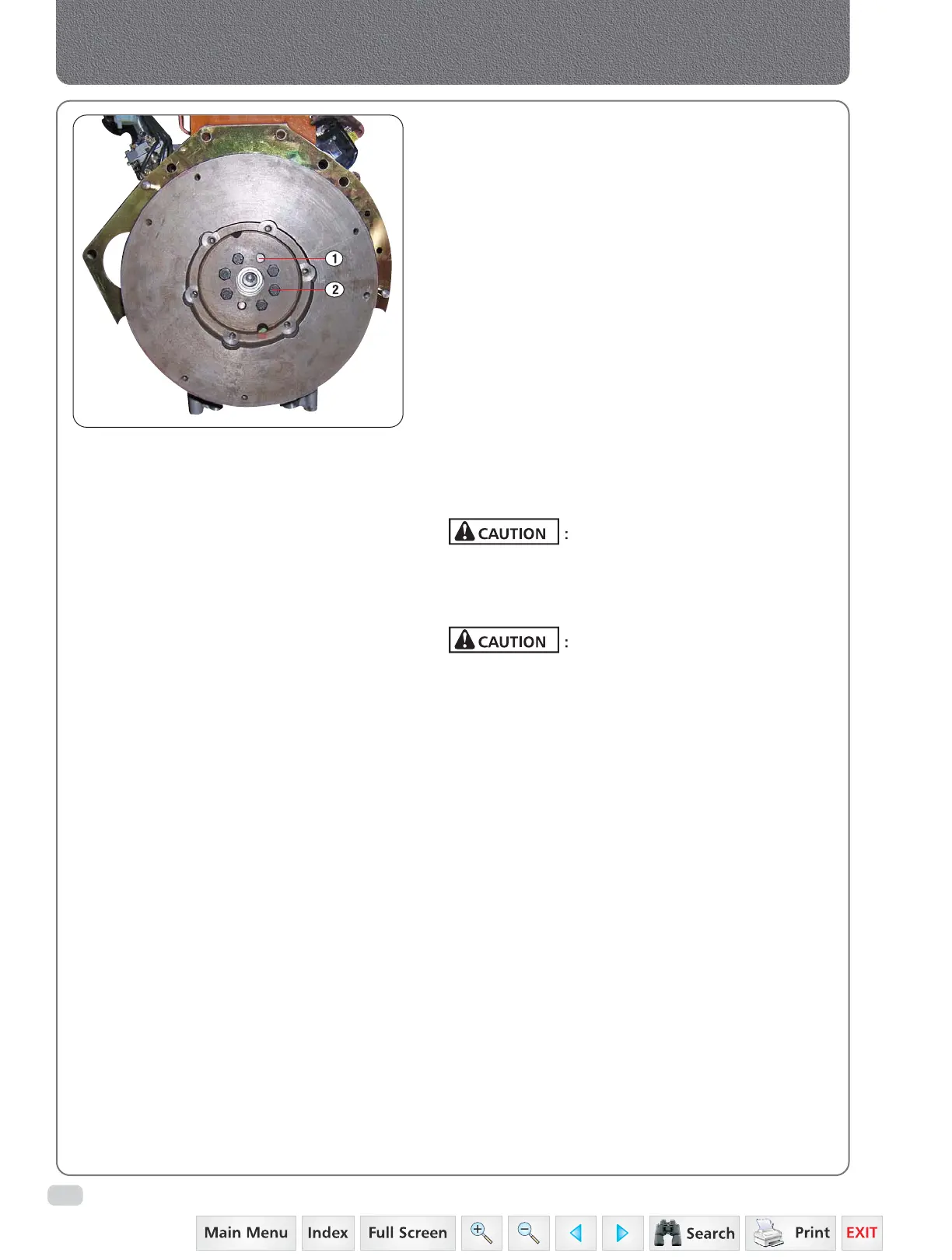

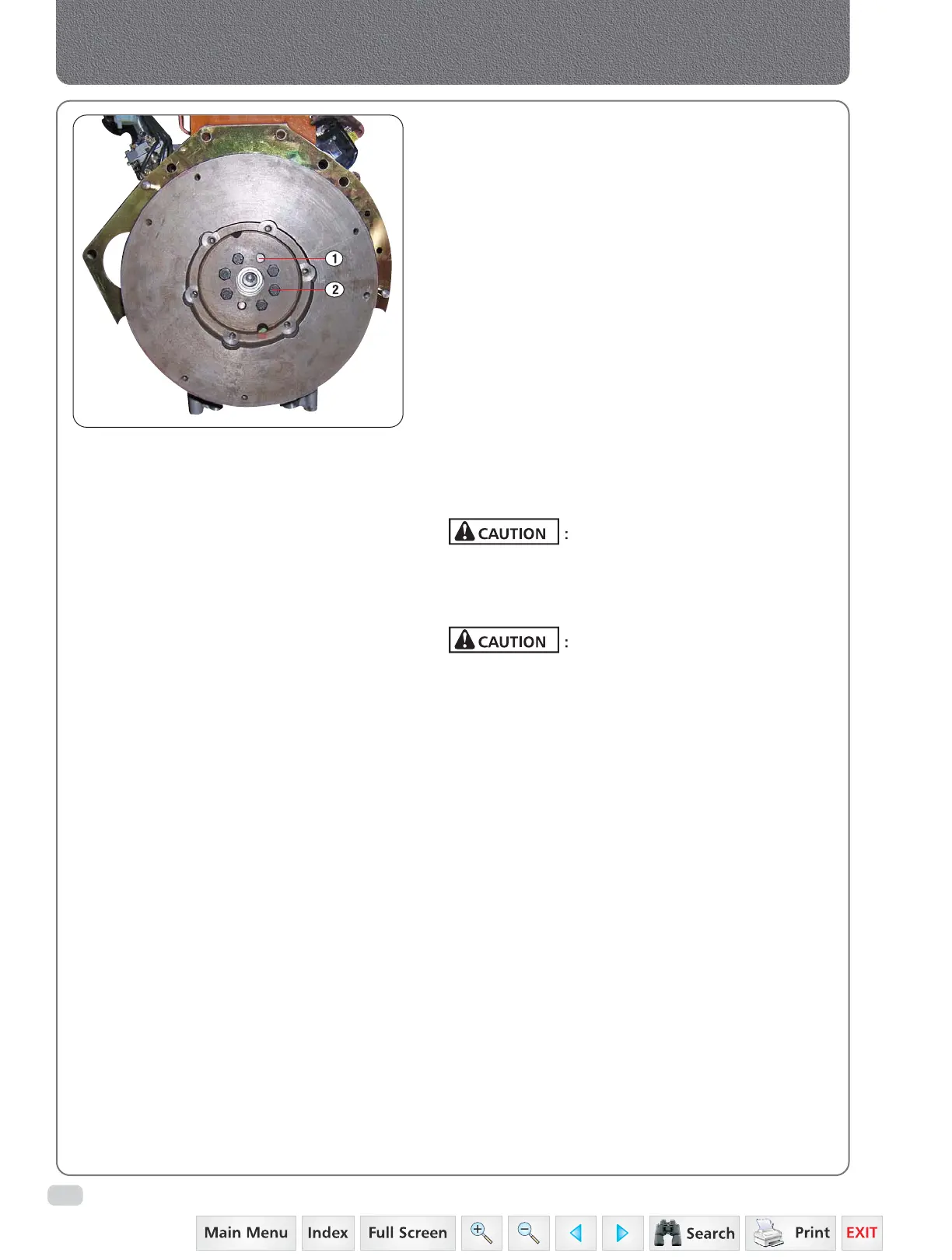

B. FLYWHEEL

1. Removal

a) Removal of the flywheel required removal of the

Engine.

b) Remove the clutch assy.

c) Remove the six bolts (2-3).

d) Using a suitable sling to support it lever the

flywheel off the dowels.

2. Inspection and Repair

a) Inspect the flywheel ring gear for excessive wear,

chipped and broken teeth.

b) If inspection proves it necessary replace the

flywheel ring gear as follows :

1. Be sure the flywheel is exactly centered when

rotating it. The friction surface must be parallel

with the dial face, deviation of more than

0.05 mm (0.002 in) are not permissible.

2. If ring gear has worked loose on the flywheel,

do not attempt by welding remove the loose gear

and replace with a new one or replace flywheel

with ring gear.

1. Remove the ring gear by heating with a torch

or splitting with a chisel and driving off.

2. Heat a new ring gear to 400-550

0

F and install

it ensuring that it is hard against the

shoulder on the flywheel. The ring gear must

be installed with the lead on the teeth

towards the crankcase on diesel engines

(1-1). Permissible out of true of ring gear

= 0.3 mm (0.012 in).

c) Inspect the clutch friction surface for ridges,

scores, grooves, cracks and burn spots.

d) Using a straight edge and feeler gauges check the

friction face for hollows or high spots. The friction

face must be flat and true within 0.006 inch.

If necessary, the friction face should be ground

to this condition. If suitable grinding equipment

is not available the flywheel can be mounted in

a lathe and the friction face dressed with emery

cloth. If the surface is very rough take a fine cut

with a lather tool before dressing the friction face

with emery cloth.

Fig. 3

Crankcase, Crankshaft, Main Bearings & Flywheel

Loading...

Loading...