I-9

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

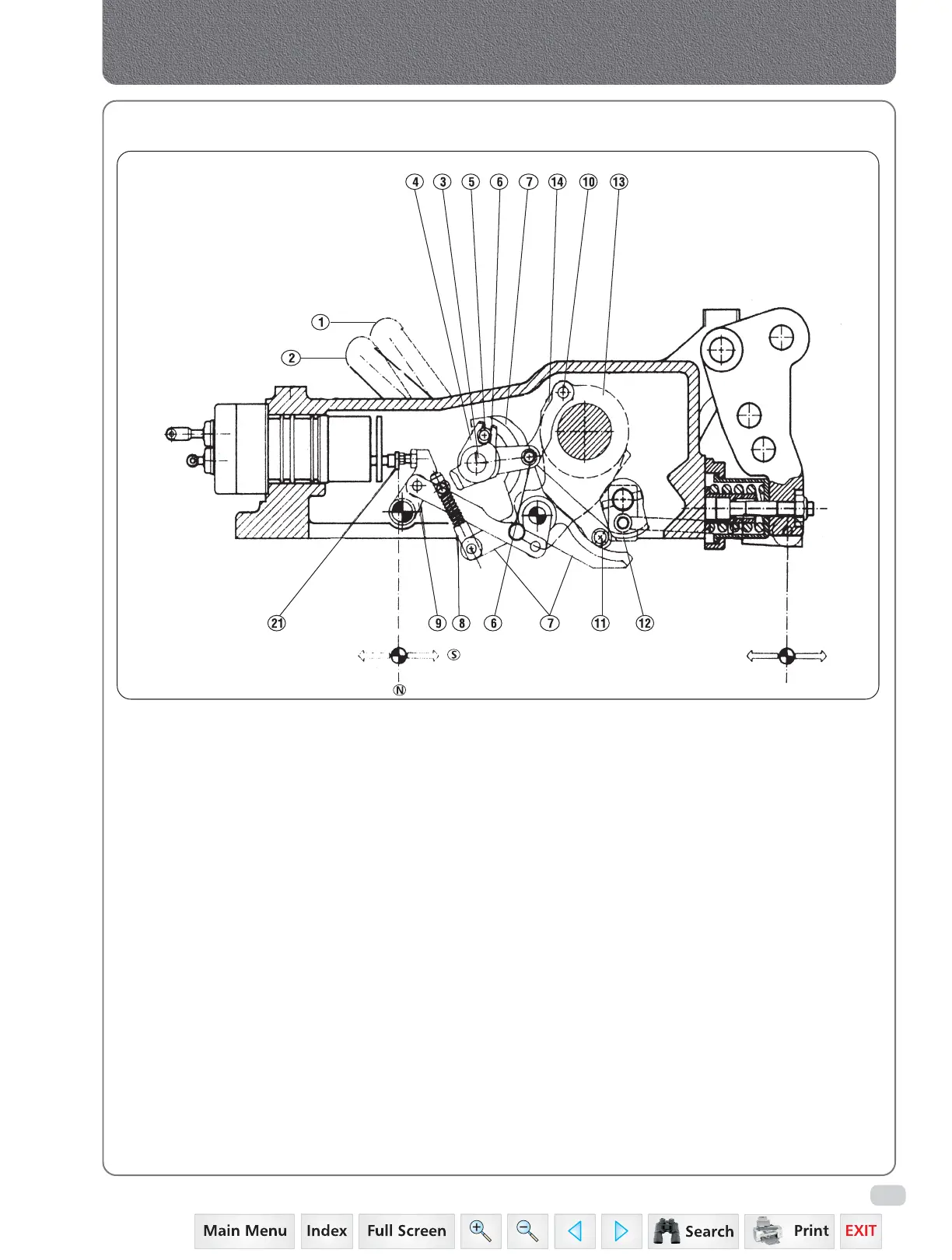

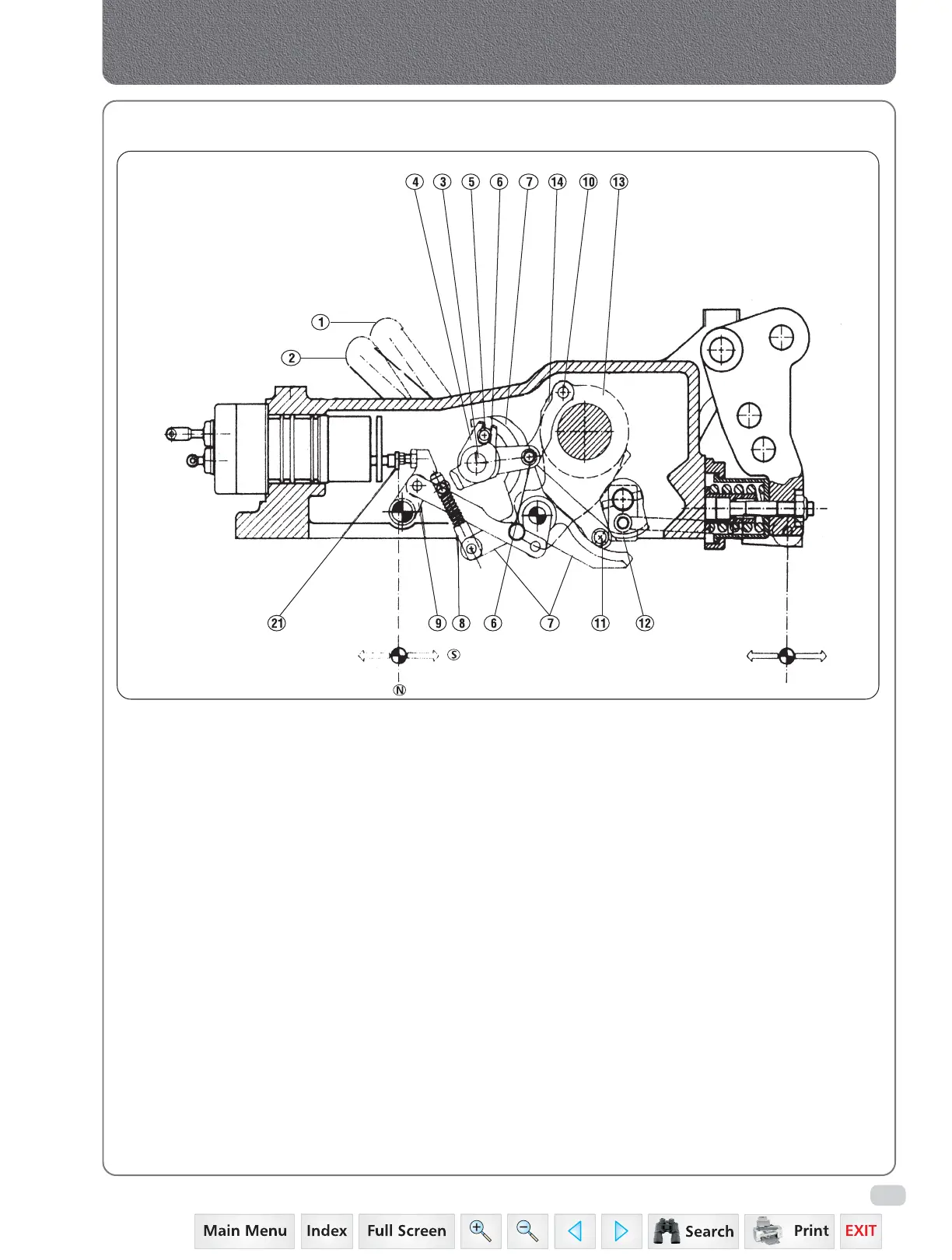

5. HOW THE INTERNAL LEVERAGE SYSTEM FUNCTIONS

a. FUNCTIONING OF POSITION CONTROL

b. FUNCTIONING OF DRAFT CONTROL

c. COMBINED FUNCTIONING OF POSITION

AND DRAFT CONTROL

A. FUNCTIONING WITH POSITION CONTROL

By positioning the draft control lever (2) against

the backstop (E) the roller (11), which slides on

the flywheel (7) of draft cam (12), will be moved

away completely.

In this way the draft levers will not in any way

interfere with the operation of the position

control. The arms are raised by moving the

position control lever (1) upward, and the

leverage system will act in the following way:

Crank (4) being an integral part of shaft (3) turns

in a clockwise direction and causes roller (5) to

slide on the position cam (6), in turn causing the

clockwise rotation of flywheel (7). The flywheel

will transmit an anticlockwise rotation, by means

of friction shock absorber (8), to the transmission

lever (9) that will bring distributor shaft (21) into

delivery position (C), thus causing the arms to

be lifted.

During the lifting movement of the arms, crank

(13) with pin (10) will rotate in an anti-clockwise

direction, and by means of the link (14) will cause

position cam (6) to rotate clockwise.

When the roller (5) meets the inclined plane of

the cam (6), it allows the anti-clockwise rotation

of the flywheel (7) that by means of a friction

shock absorber (8) rotates the lever (9) in a

clockwise direction, which is pushed by the spring

of the control valve shaft (21) which moves to

position (N) (neutral phase) and thus blocking

the movement of the lifting arms.

During the lowering phase of the arms the

movements of the levers indicated above will

occur in the opposite sense.

The position of the arms, during lifting and

lowering, correspond to a specific position of the

position control lever (1).

Positive

Stroke

+

Negative

Stroke

-

Hydraulics

Loading...

Loading...