C-38

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

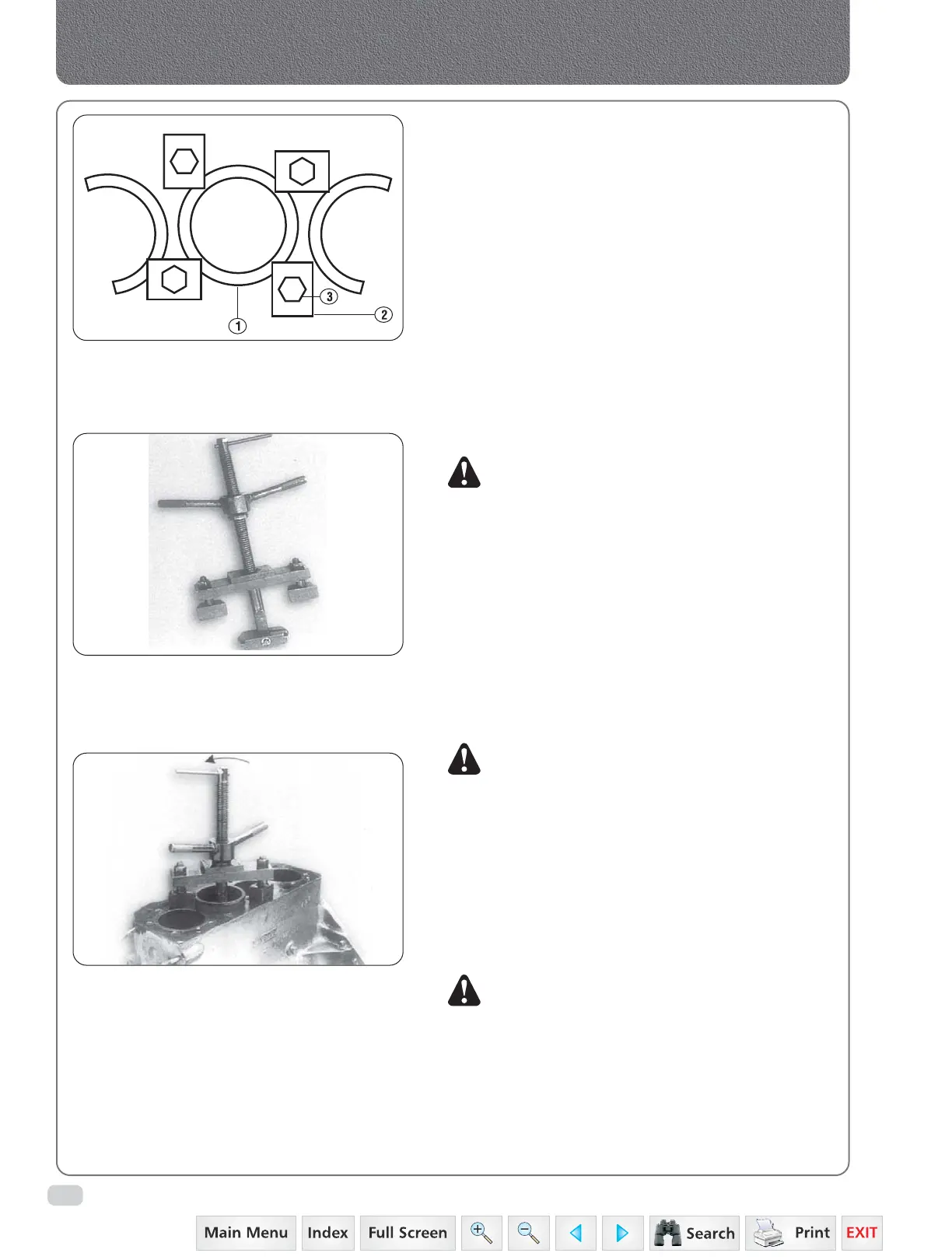

MST-H1-EN-1 (fig.13) as follows :

• Insert the sleeve puller from the top of the

crankcase (fig.14).

• Fix the thrust plate sides at lower portion

of cylinder sleeve. The bigger side of thrust

plate is suitable for DI Engine.

• Position the bracket on top of the crankcase

and tighten the nut over the bracket of puller

bar, by rotating handle, the sleeve will be

pulled out while tightening the nut.

c) Before installing sleeve, check the counter bore

at top and sealing ring groove at the bottom are

clean and free from foreign material. All sleeves

should enter crankcase bores full depth and should

free to rotate by hand (without sealing ring).

NOTE: The cylinder head gasket forms the upper

cylinder sleeve seal, and excessive sleeve stand

out will result in coolant leakage. To test lower

sealing rings for proper installation, fill crank

case water jacket with cold water and check

for leaks near bottom of sleeves.

d) Check the sleeves for scoring or signs of corrosion.

3. INSTALLATION

a) Dip each cylinder sleeve packing ring in a soap

solution and install it in the groove in the

crankcase bore.

b) Coat bottom of each sleeve with soap solution

and press the sleeve into the crankcase bore.

NOTE: Weights refer to complete connecting rods with

bushing, bearing cap and bolts but less

securing wire and without bearing halves.

c) Check from below to ensure that the packing rings

have not been sheared or pushed out of position.

d) Check the cylinder sleeve protrusion (Fig.11) to

specifications. The top face of the sleeve can be

0.05 mm above the cylinder block face or 0.03 mm

below the cylinder block face. To ensure the above

dimension, the cylinder sleeve and the cylinder

block should be matched.

NOTE: Check cylinder sleeve protrusion according to

checking sleeve protrusion procedure given

below :

e) Install the piston assemblies.

1. Place the sleeve in the crankcase with out

‘O’ Ring.

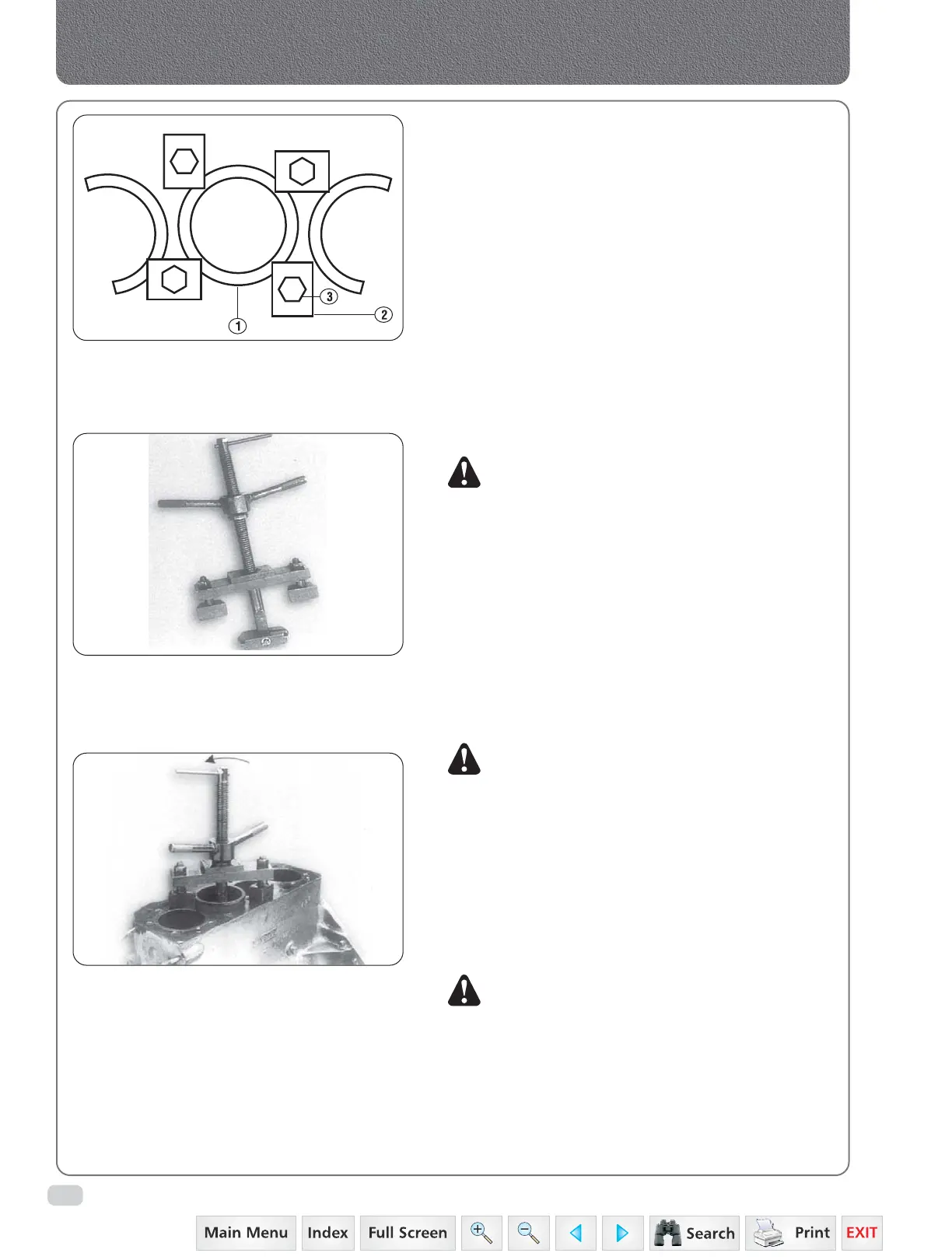

2. Clamp the sleeve down using four holding

adapters/plate shown in fig.12 place sleeve

holding plate locally.

Fig. 12

1. Sleeve 2. Holding plate 3. Bolt

Fig. 13

Fig. 14

Connecting Rods, Pistons & Cylinder Sleeves

Image is representative

Loading...

Loading...