A-13

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

Priming the Lubrication System

NOTE : Diesel engines must not be rotated when

priming with oil; otherwise, they are likely

to start running.

When assembling the overhauled engine, it is

necessary to thoroughly lubricate the various

running parts with clean engine oil to assure initial

lubrication when engine is first started.

However, to further make certain that complete

initial lubrication is available, the engine lubricating

system should be pressure primed or charged with

oil. Attach the line from a priming device to a

suitable fitting located in the main oil gallery, filter

header or oil cooler of the engine and inject

sufficient oil into the engine to fill the oil filters

and charge the entire system. Use only clean engine

oil in accordance with Operator’s Manual. New or

overhauled engines that have been in storage over

an extended period should also be primed

in a similar manner.

After the priming procedure is completed, make

certain that the oil level is checked before the engine

is put into service. Do not overfill the engine; neither

should engine be short of oil as a result of using

the pressure priming procedure.

Priming the engine will minimize the possibility of

scuffing or heat build-up in the running components

which could lead to immediate or low hours of use

failures.

Engine Run-in Schedule

NOTE : Do not run the engine at low or high idle

speeds for long period after installing new

rings or sleeves, as rings will not seat

during idle operation.

Start

Prior to starting make sure, that

a) all bearings are pre-lubricated

b) the crankcase is filled with specified engine

oil

c) the cooling system is filled correct level

d) Precautions for alternator operation are

observed.

Run-in

1. Start and run engine at 3/4 rated engine

speed with no load, until operating

temperature (80-85

0

C) (164-172

0

F) is reached,

cover the radiator if necessary, DO NOT run

for over 10 Minutes.

2. Retorque cylinder head bolts.

DO NOT run the engine longer

than 15 Minutes, before retorquing cylinder head

bolts.

3. Continue according to the following chart.

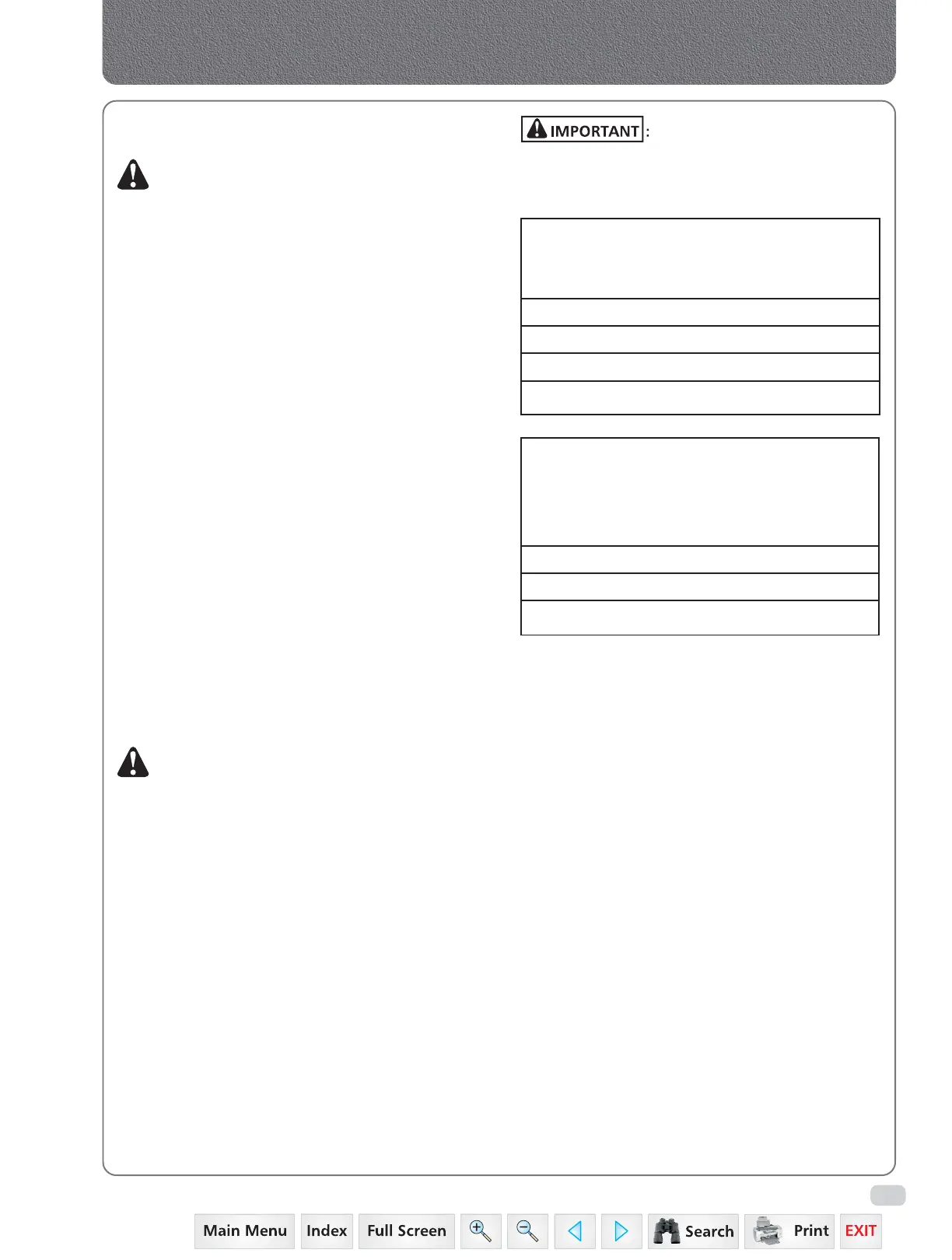

with Dynamometer

Engine Load Time

RPM % minutes

1400 40 5

2000 50 5

rated speed 80 10

100 below rated speed 50 10

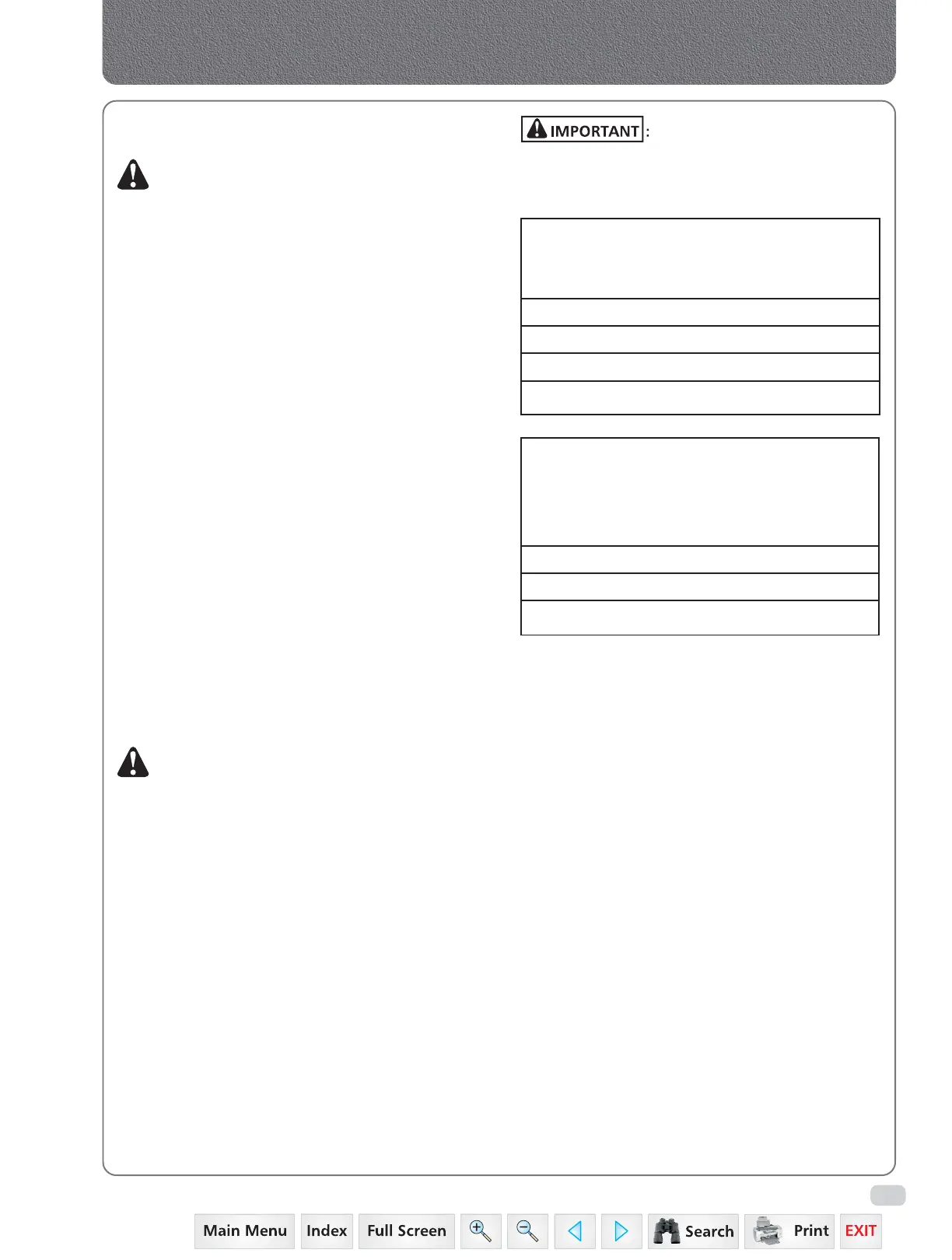

without Dynamometer

(In-Vehicle Run-in Procedure)

Engine Load Time

RPM % minutes

3/4 of rated light 5

3/4 of rated medium 15

rated speed full 20

After Running-in

Retighten manifold bolts and/or stud nuts.

Re Torque the cylinder bolts and check valve

clearance and readjust as necessary.

Handing over the Engine

In the presence of the operator check engine oil

level and coolant level. Test run the engine.

Point out to the operator that the overhauled engine

is to be treated in the same way as a new one.

General

Loading...

Loading...