A-20

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

General

BLEEDING FUEL SYSTEM

Air must be removed

1) When the fuel filter or lines are removed.

2) When water is drained from fuel filter.

3) When tank is completely empty.

4) When tractor is not used for a long period of

time.

Fuel filter provides clean, moisture free fuel for the

injection process. A hand primer is provided to

manually remove excess air from the fuel filter and fuel

lines.

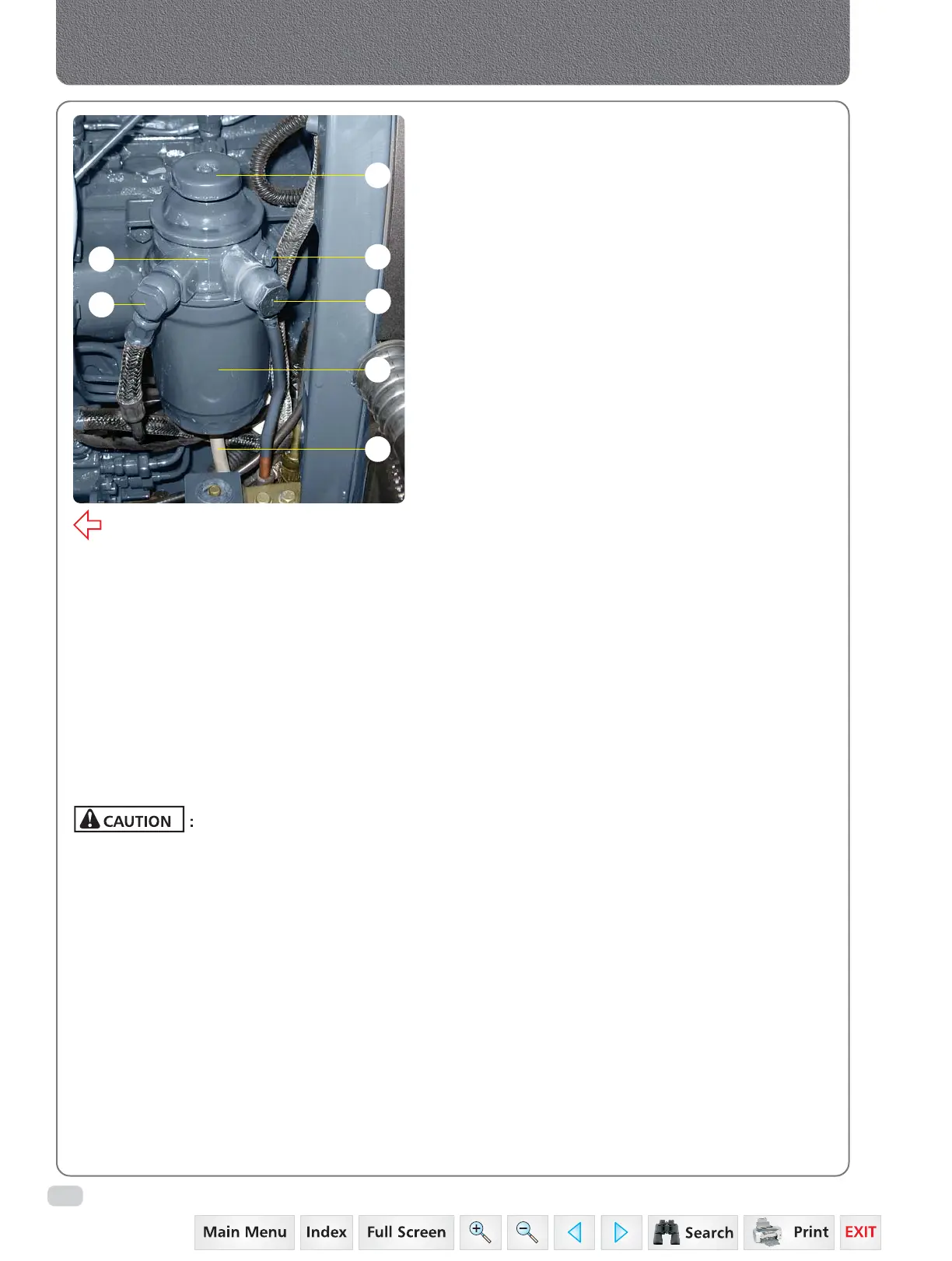

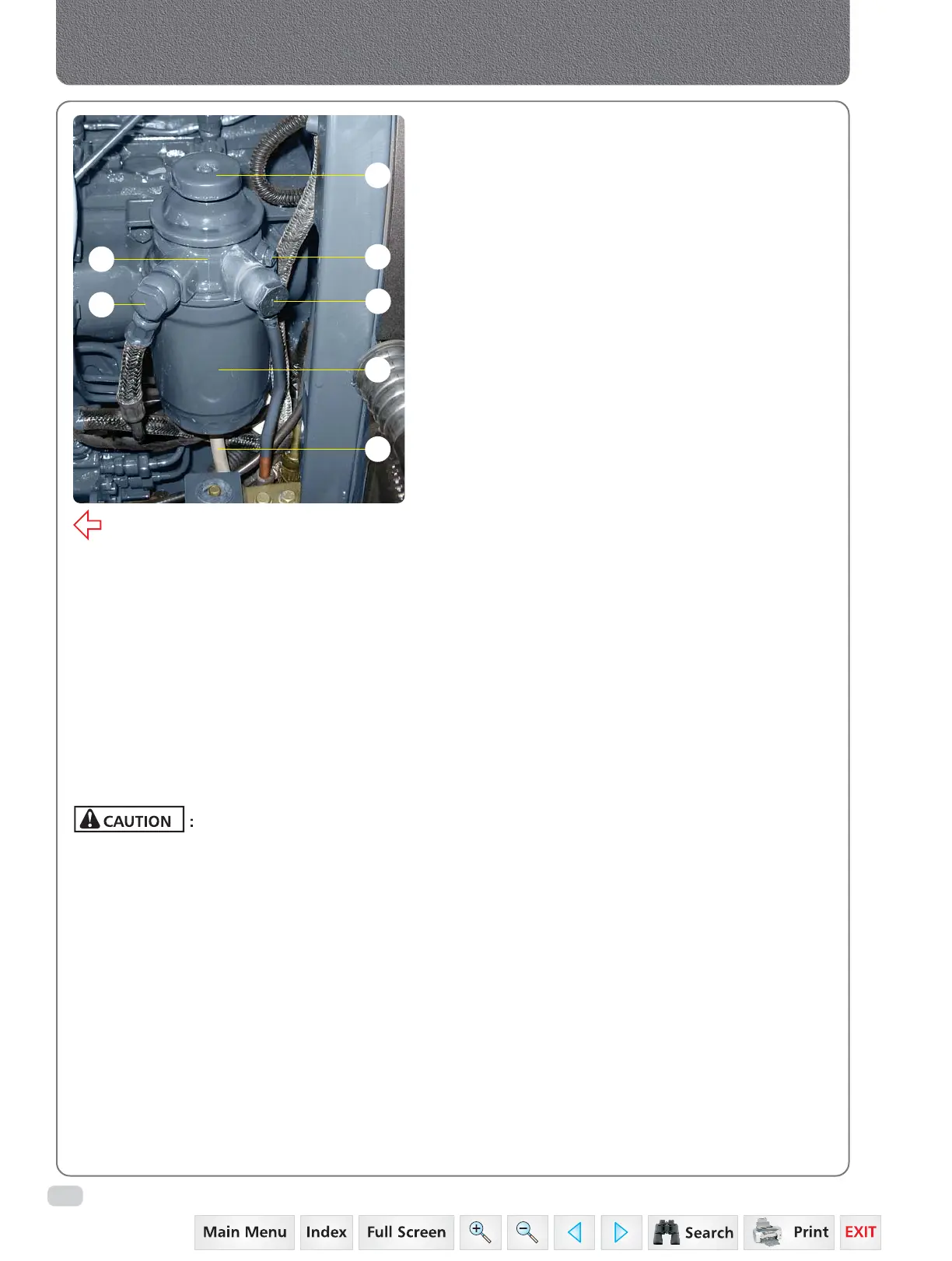

Major Components:

• Hand Primer (F)

• Air Bleeding Screw (G)

• Fuel Filter (D)

Fuel enters the filter at inlet (A) and flows through the

filter element separating water if contents before

flowing through outlets (B) to the fuel injection pump.

Since water and contaminants settle at the

bottom of the sediment bowl, a drain plug is

provided at the bottom of the filter. Drain water

in fuel, by loosening drain plug once every

50 hrs. of operation.

To drain water in fuel, loosen the drain plug upto

1 or 2 turns. During loosening drain plug,

place a small tray to collect the water coming

from pipe (C). Retighten the drain plug by hand.

Servicing the fuel filter

1. It is recommended to replace the fuel filter every

500 hrs.

2. To remove Filter, unscrew the filter (D) from

adaptor (E).

3. Check O'rings of fuel filter for any crack / damage.

Smear oil on the new O'ring before installation.

4. Clean the adaptor with clean diesel from inlet and

outlet. Ensure no dirt, foreign particles entangled

in flap valves or filter head.

5. Assemble the new filter. Do not over tighten.

6. Prime the system and bleed the filter. Tighten the

bleeding screw.

Note : Drain water once in a week or earlier if

water contamination is excessive. Continued

driving with water accumulation in fuel filter

will cause damage to fuel pump / other fuel

system components.

Note : Replace fuel filter at the recommended

period or whenever it gets clogged. Discard

the old filter and do not repair or clean the

filter.

Always fit the spin-on filter dry.

Tractor Front

F

A

D

C

B

G

E

Do not hold key at engine start position for

more than 10 seconds continuously. If more

engine cranking is needed try again after

30 seconds.

Always close the air vent screw except for

bleeding fuel lines other wise, engine will run

irregularly or stall frequently.

Loading...

Loading...