C-22

35 Series 4WD, Model - 3535, 4035, 4535 and 5035 SM June’08

2b. INSTALLATION :

a) Reverse the removal procedure.

b) It is always advisable to replace the Inlet & exhaust

manifold gaskets with new ones.

c) Torque the mounting bolts at the specified torque

to avoid leakage of gases.

2c. CLEANING, INSPECTION & REPAIR

Clean the manifold and inspect for cracks and distortion.

Replace the manifold with New one, whenever distortion

is more than 0.4 mm (.016 in) per 250mm (10 inch)

length. Inspect Air Hose & Clamps. Inspect retainer bolts

and their washers, replace damage parts.

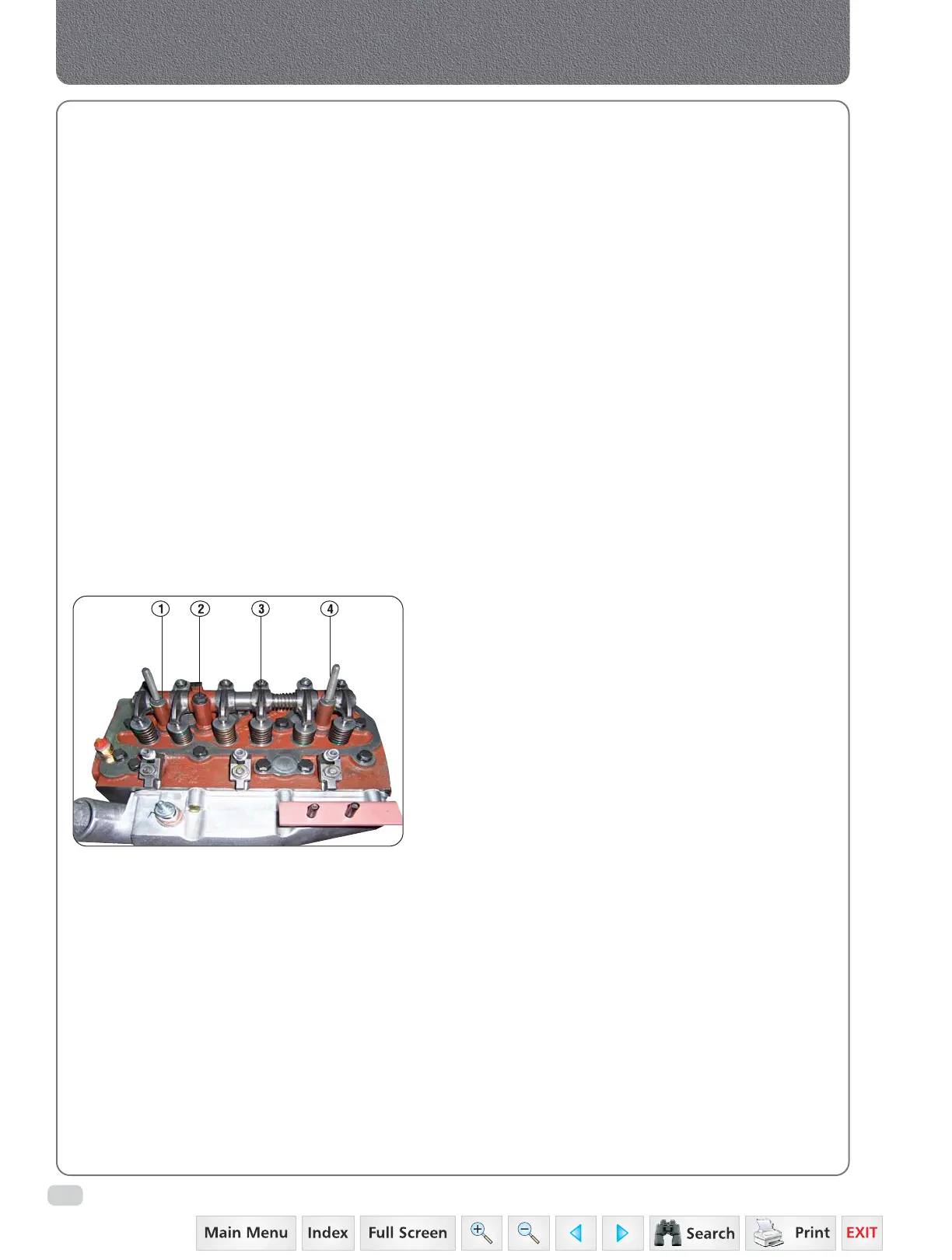

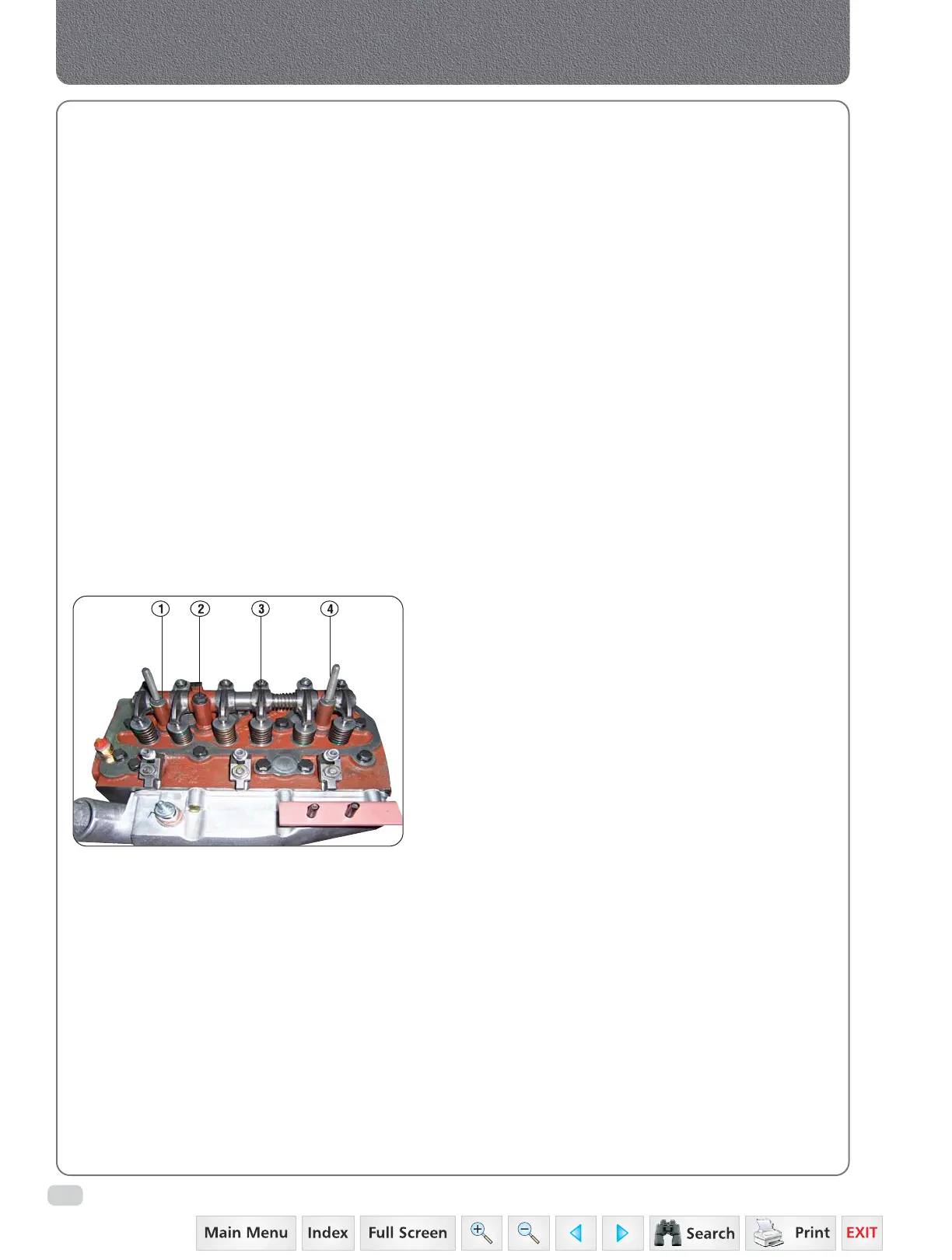

3. VALVE ROCKER ARM SHAFT ASSEMBLY

3a. REMOVAL :

Thoroughly clean the engine externally.

a) Remove the radiator brace, clamps/stiffener and

rubber washer. Then remove the valve housing

cover and the gasket.

b) Remove the PCV.

c) Remove the two nut (1-3) from studs (4-3) from

the outer valve lever shaft bracket. Which hold

the valve lever shaft brackets cylinder head.

d) Remove the bolt (2-3) from the centre (long valve

lever bracket.

e) Lift of the valve rocker arm shaft and brackets.

f) Lift out the push rods marking them so that they

may be returned to their original positions.

3b. DISMANTLING :

Rocker Arm shaft

a) Remove circlip from both ends of the shaft

and take out Rocker Arms and other parts

(10 to 25-7).

b) To shift from centre bracket remove the roll pin

and remove the shaft. Identify the rocker arms

so that the can be installed in their original

position.

3c. INSPECTION & REPAIRS

a) Thoroughly clean all components in Kerosene or

Diesel and blow using compressed air.

Be sure all oil passages are free from sludge and

sediment.

b) Check the valve lever shaft expansion plugs.

c) Check the clearance between the valve rocker arm

shaft and valve rocker arm bushings.

Manifolds, Cylinder Head & Valves

Fig. 3

Loading...

Loading...