v

2.4 TO

CUT

Raise

Presserfoot 4402 above top of lay by

pressing

down on

Presserfoot Handle

,4'323 and lift ingPresserfoot

Lift .

For Squeeze

Trigger,

pull

Handle 23308 towards

machine Handle 4549.

Enter lay,

and

lower Presserfoot to top of lay by releasing

Presserfoot

Trigger. When making turns

in lay, it is

sometimes

advisable to let Presserfoot ride

freely

on top of

lay

by

pushing

down onPresserfootHandle.

When machine is not in

use, always

lower Presserfoot to Baseplate. The Presserfoot Leg acts as a

safety

guard

for the blade.

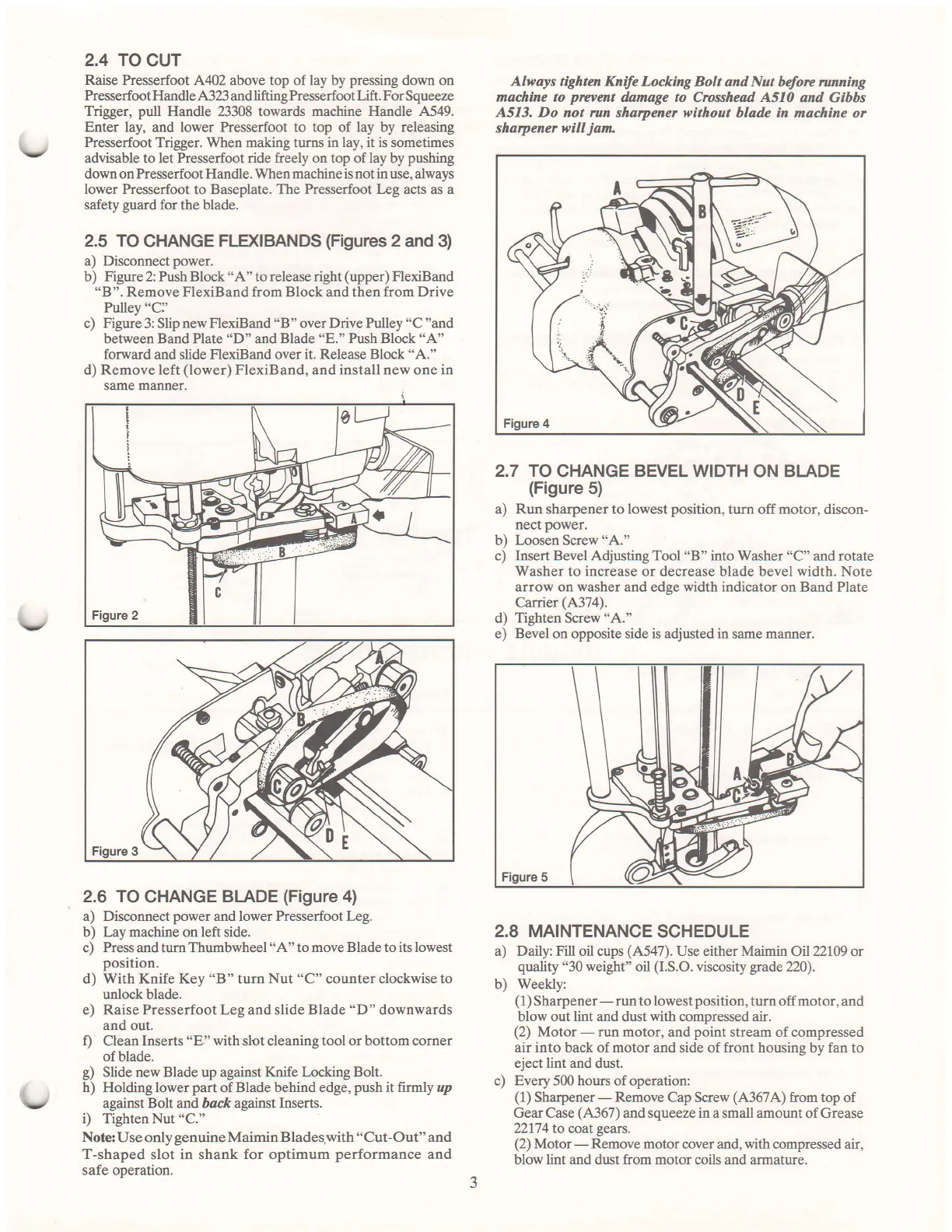

2.5 TO

CHANGE FLD(BANDS

(Figures

2

and 3)

a) Disconnect

power.

b)

Figure

2: Push Block

*A"

to

release right

(upper)

FlexiBand

"B".

Remove FlexiBand from Block and then

from Drive

Rrlley

"Cl'

c)

Figure

3: Slip

new FlexiBand "B" over Drive Pulley

"C

"and

between Band Plate

"D"

and Blade

"E."

Push Block

"A"

forward

and slide FlexiBand over

it. Release Block

*A."

d) Remove left

(lower)

FlexiBand, and install new one in

same manner.

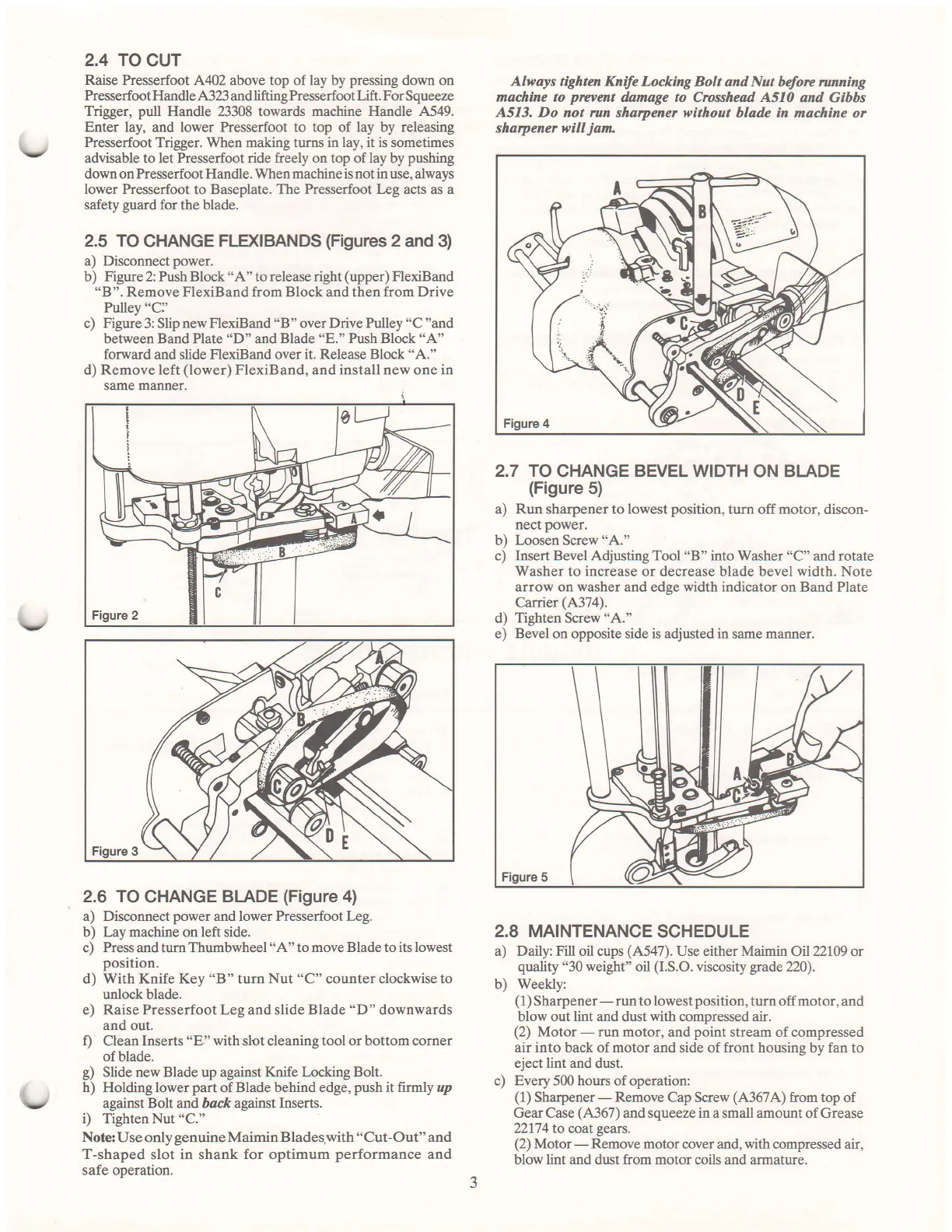

2.6 TO

CHANGE

BLADE

(Figure

4)

a) Disconnect

power

and lower Presserfoot Leg.

b) Lay machine on left side.

c) Press and turn Thumbwheel

"A"

to

move Blade to its lowest

position.

d) With Knife Key

"B"

turn Nut

"C"

counter clockwise to

unlock blade.

e) Raise Presserfoot Leg and slide Blade

"D"

downwards

and out.

f)

Clean Inserts

"E." with.slot

cleaning

tool or bottom corner

ofblade.

g)

Slide new Blade up against Knife Locking Bolt.

h)

Holding lower

part

of

Blade

behind

edge,

push

it firmly up

against Bolt and back against Inserts.

i) Tighten Nut

"C."

Note: IJse only

genuine

Maimin

Blades,with "Cut-Out" and

T-shaped

slot in shank

for

optimum

performance

and

safe operation.

Always tighten Knife

Locking Boh and Nut

beforc nmning

machine to

prevent

damage to

Crosshead

A510

and Gibbs

A513. Do

not

run

sharyrener withoat blade in machine

or

sharTrener wiII

jan

2.7 TO

CHANGE

BEVELWIDTH

ON BLADE

(Figure

5)

a) Run sharpener to lowest

position,

turn offmotor, discon-

nect

power.

b)

Loosen

Screw

"A."

c) Insert Bevel Adjusting Tool

"B"

into Washer "C"

and

rotate

Washer

to

increase

or decrease blade bevel

width.

Note

arrow on washer and

edse

width indicator

on

Band

Plate

Carrier

(4374).

d)

Tighten

Screw

"A."

e) Bevel

on

opposite

side

is

adjusted

in

same

manner.

2.8 MAINTENANCE

SCHEDULE

a) Daily: Fill oil cups

(A547).

Use

either

Maimin

01122109 or

quality

"30 weight"

oil

(I.S.O.

viscosity

grade

220).

b) Weekly:

(1)

Sharpener-run

to

lowestposition,

turn off motor, and

blow out lint and dust with compressed air.

(2)

Motor

-

run motor,

and

point

stream of compressed

air into back of motor

and side of

front housing

by fan to

eject lint and dust.

c) Every500hours of operation:

(1)

Sharpener-

Remove

Cap Screw

(4'367A)

from top of

Gear Case

(A367

)

and squeeze

in

a small amount of Grease

22174

to coat

gears.

(2)

Motor

-

Remove motor

cover and,

with

compressed air,

blow lint and dust from motor

coils and armature.

v

Loading...

Loading...