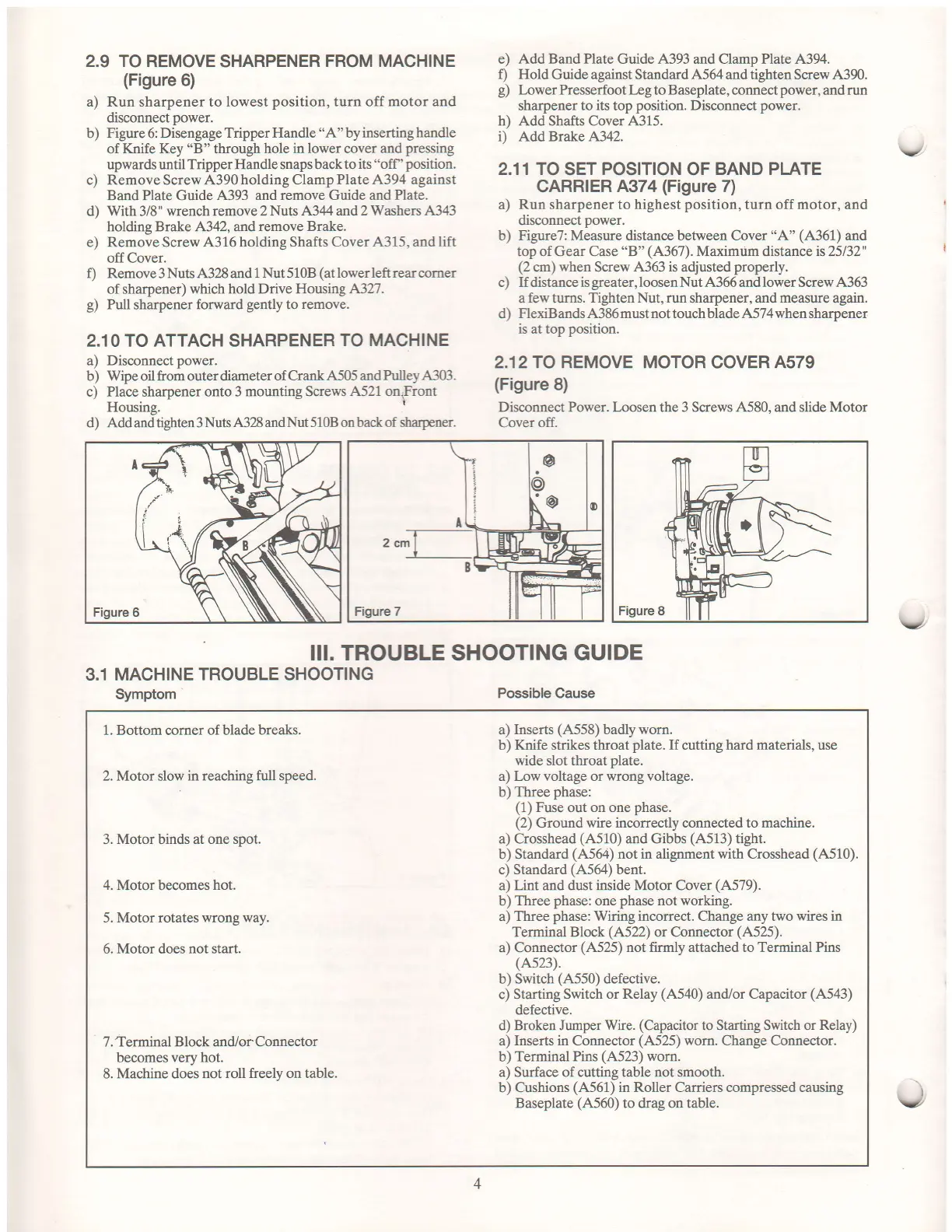

2.9 TO REMOVE

SHARPENER

FROM MACHINE

(Figure

6)

a) Run sharpener to lowest

position,

turn off motor and

disconnect

power.

b)

Figure

6: Disengage

Tripper Handle

"A"

by

inserting handle

of

Knife Key

"B"

through

hole in

lower

cover

and

pressing

upwards until

Tripper Handle snaps back to

its "off

'

position.

c) RemoveScrew.4'390holdingClampPlate,4'394

against

Band Plate Guide

,4393 and remove Guide and

Plate.

d) With 3/8" wrench remove 2

Nuts ,4.344 and 2 Washers ,4'343

holding Brake 4342, andremove

Brake.

e) RemoveScrew

,{316 holding Shafts Cover

4315,

and

lift

offCover.

f) Remove 3 Nuts 4'328 and 1

Nut

5

10B

(at

lower left rear corner

of sharpener)

which hold Drive Housing 4327.

g)

Pull

sharpener

forward

gently

to

remove.

2.10 TO

ATTACH

SHARPENER

TO MACHINE

a) Disconnect

power.

b) Wipe oil from outer diameter

of CrankA5O5 andPulleyA303.

c)

Place

sharpener

onto 3 mounting Screws

,4'521 on,Front

Housing.

I

d) Add and tighten 3

Nuts ,{328 and Nut 5108 on back of Sarpener.

III. TROUBLE SHOOTING

GUIDE

3.1 MACHINE

TROUBLE SHOOTING

Symptom

Possible Cause

e)

Add Band Plate

Guide A393 and Clamp Plate 4'394.

f) Hold

Guide against Standard

,4.564

and tighten Screw 4390.

g)

Lower Presserfoot Leg to Baseplate, connect

power,

and

run

sharpener to

its

top

position.

Disconnect

power.

h) Add Shafts Cover 4315.

i) Add Brake A342.

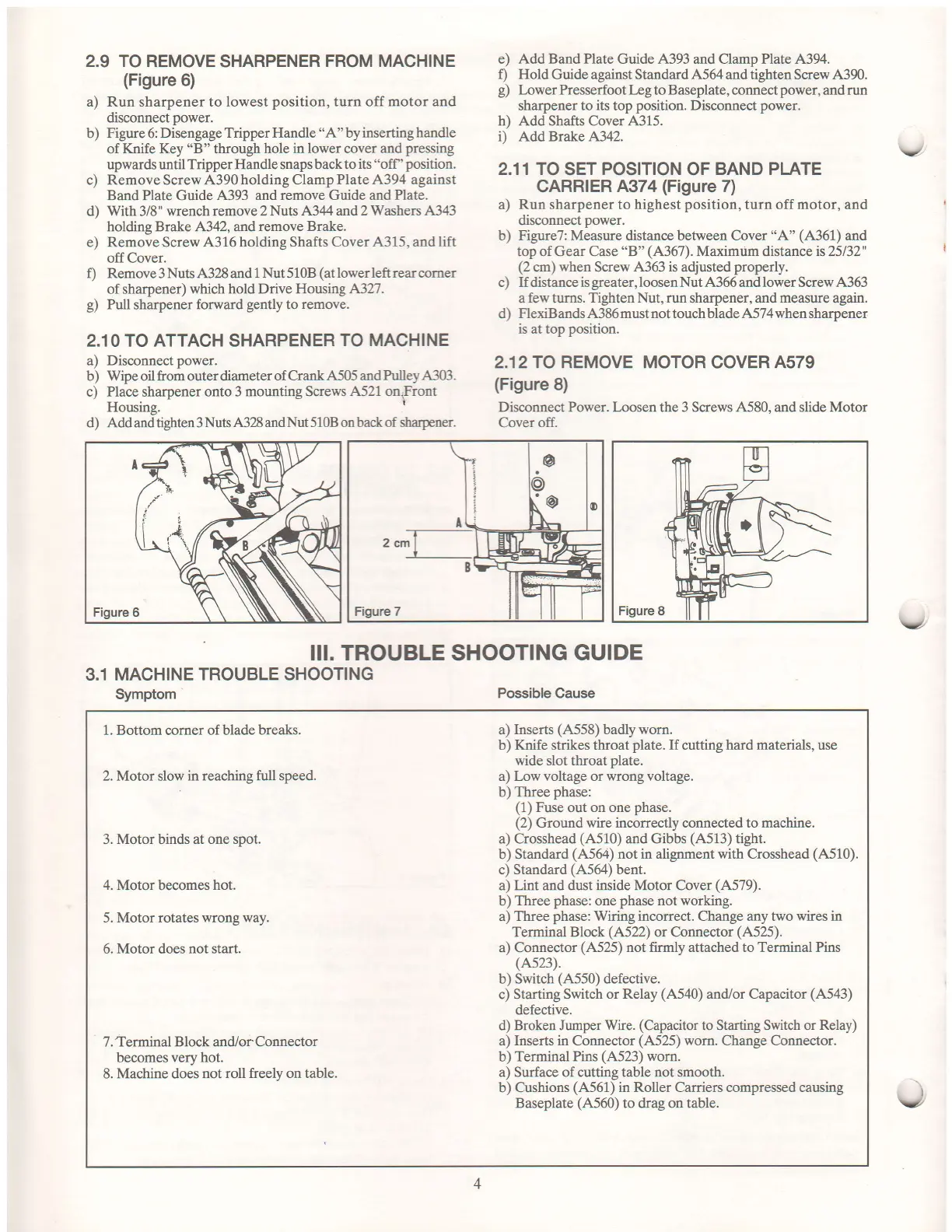

2.11 TO

SET

POSITION

OF

BAND PLATE

CARRIER

4374

(Figure

7)

a) Run sharpener to

highest

position,

turn off

motor,

and

disconnect

power.

b) Figure7: Measure distance between Cover

"A"

(A361)

and

top of Gear Case

"B"

(4367).

Maximum

distance

is25132"

(2

cm)

when

Screw

4'363 is

adjusted

properly.

c) If distance is

greater,

loosen Nut .4'366 and lower Screw A363

a

few

turns.

Tighten Nut, run

sharpener, and

measure

again.

d)

FlexiBands ,4'386 must not touch blade ,4'574 when sharpener

is at top

position.

2.12TO REMOVE MOTOR COVER A579

(Figure

8)

Disconnect Power. Loosen the 3 Screws A,580, and slide Motor

Cover off.

v

v

1. Bottom comer of blade

breaks.

2. Motor

slow

in reaching ftrll speed.

3.

Motor binds at one spot.

4.

Motor becomes

hot.

5. Motor rotates

wrong way.

6. Motor does

not start.

7. Terminal Block and/or Connector

becomes very hot.

8. Machine does

not roll freely on table.

a)

Inserts

(,4'558)

badly worn.

b) Ifuife strikes throat

plate.

If

cutting

hard materials,

use

wide slot throat

plate.

a) Low voltage or wrong voltage.

b) Three

phase:

(1)

Fuse

out

on one

phase.

(2)

Ground

wire incorrectly connected to machine.

a) Crosshead

(4'510)

and Gibbs

(A513)

tight.

b) Standard

(4'564)

not in alignment with Crosshead

(,{510).

c)

Standard

(,4'564)

bent.

a) Lint and dust inside Motor Cover

(A579).

b)

Three

phase:

one

phase

not working.

a)

Three

phase:

Wiring incorrect. Change any two

wires

in

Terminal Block

(A522)

or Connector

(A525).

a) Connector

(4.525)

not firmly attached to Terminal Pins

(4523\.

b) Switch

(,4,550)

defective.

c) Starting Switch or

Relay

(4'540)

and/or Capacitor

(4'543)

defective.

d) Broken Jumper Wire.

(Capacitor

to Starting Switch or

Relay)

a)

Inserts in Connector

(A525)

worn. Change Connector.

b)

Terminal Pins

(4523)

wom.

a) Surface of cutting table not smooth.

b) Cushions

(4'561)

in Roller Carriers compressed causing

Baseplate

(4'560)

to drag on table.

4

I

Loading...

Loading...