P 2/ 9

Repair

CAUTION: Repair the machine in accordance with “Instruction manual” or “Safety instructions”.

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATIONS

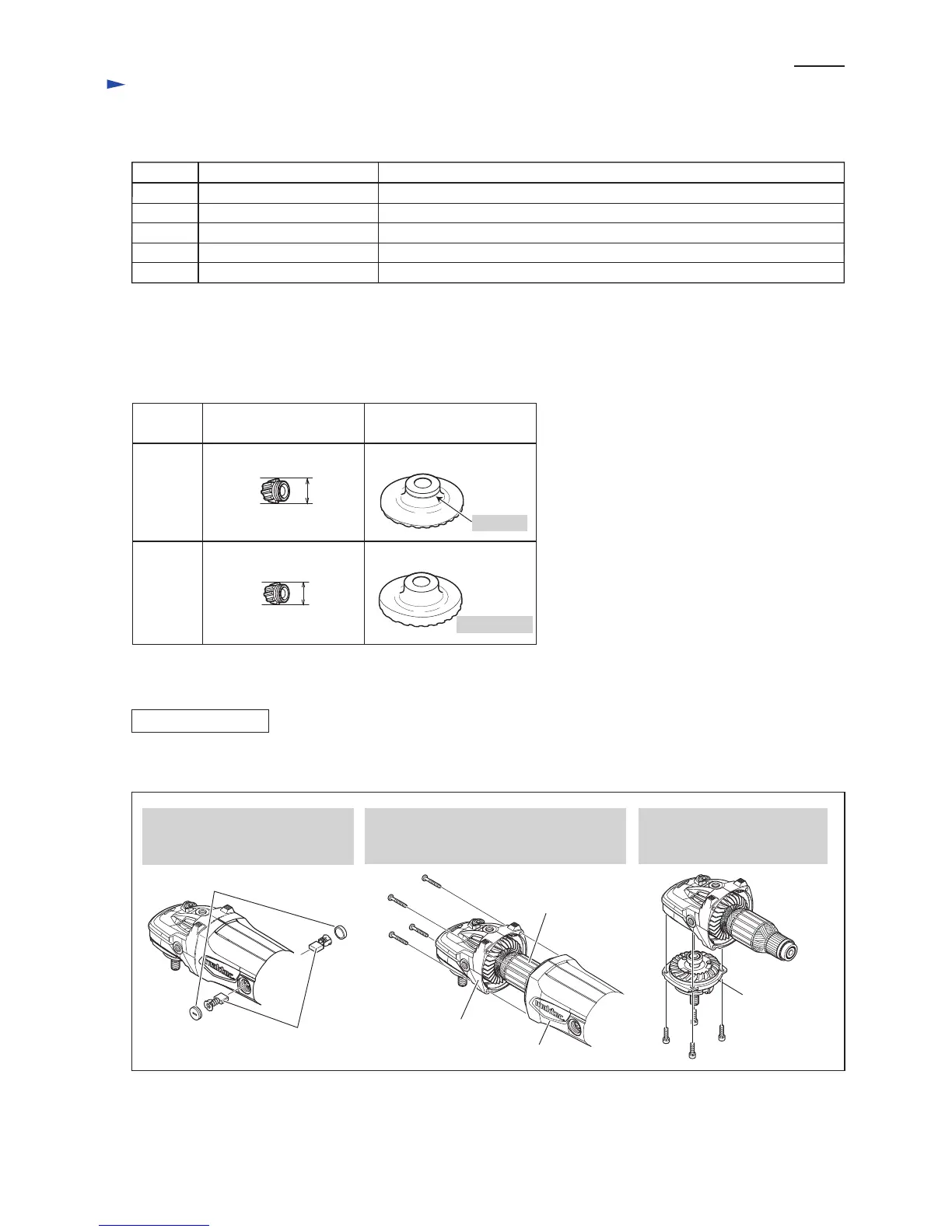

[3] DIFFERENCE OF GEARS BETWEEN MT902 AND MT903

[4] DISASSEMBLY/ASSEMBLY

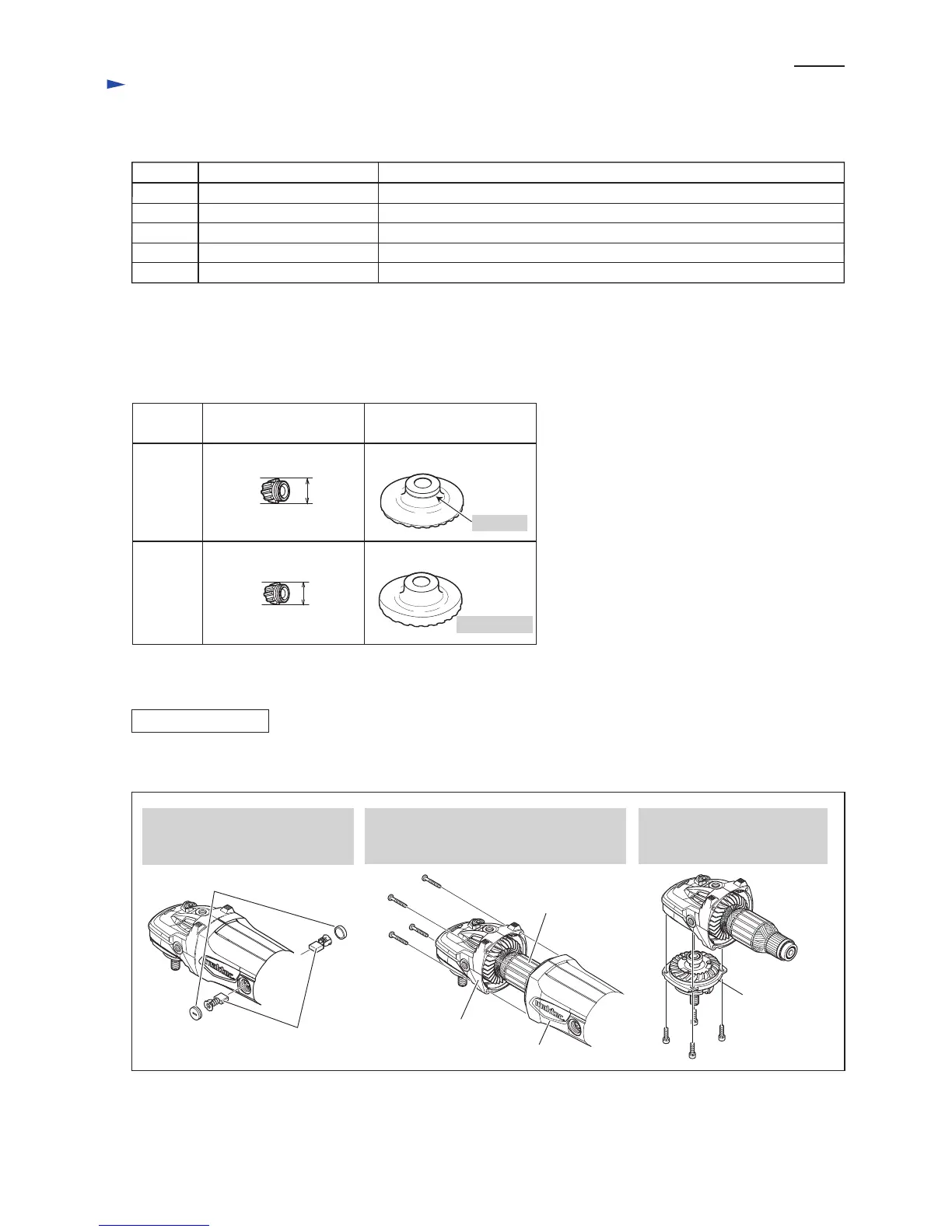

[4]-1. Small spiral bevel gear, Armature, Ball bearings 6301ZZ and 6200ZZ

Code No. Description Use for

1R004 Retaining ring pliers ST-2 disassembling/ assembling Ring spring 15

disassembling/ assembling Retaining ring R-421R005 Retaining ring pliers RT-2N

1R027 Bearing setting pipe 18-10.2 disassembling Large spiral bevel gear from Spindle

1R269 Bearing extractor (small) removing Ball bearings

1R286

Model No.

Small spiral bevel gear

(Gear on Armature shaft)

Large spiral bevel gear

(Gear on Spindle)

Round bar for Arbor disassembling large Spiral bevel gear from Spindle

Apply approx. 70g of Makita grease N No.1 to Gear room.

Refer to the following gears. They are not interchangeable.

DISASSEMBLING

MT902

MT903

Number of teeth: 16

Spiral bevel gear 16

Spiral bevel gear 12

Spiral bevel gear 53B

Spiral bevel gear 53A

Number of teeth: 12

28mm

22mm

grooved

not grooved

1. Remove Brush holder caps and

Carbon brushes from Motor

housing.

(1) Disassemble Gear housing complete and Bearing box. (Fig. 1)

2. Remove Gear housing complete together

with Armature from Motor housing by

unscrewing four 5x35 Tapping screws.

3. Remove Bearing box section

by unscrewing four 5x35

Hex socket head bolts.

Fig. 1

Brush holder caps

Carbon brushes

Gear housing complete

Motor housing

Armature

Bearing box

section

5x35 Tapping screw (4pcs.)

5x35 Tapping

screw (4pcs.)

Loading...

Loading...