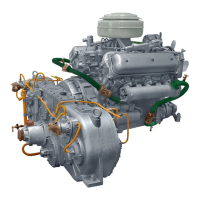

Technical data

61

Start of delivery

D 2842 LE 401 / 402 22° ± 0,5° before TDC

D 2842 LE 403

with optimised consumption

with optimised NO

x

15° ± 0,5° before TDC

12° ± 0,5° before TDC

D 2842 LE 406

with optimised consumption

with optimised NO

x

24° ± 0,5° before TDC

21° ± 0,5° before TDC

D 2842 LE 408

with optimised consumption

with optimised NO

x

20° ± 0,5° before TDC

18° ± 0,5° before TDC

D 2842 LE 411 18° ± 0,5° before TDC

D 2842 LE 412 13° ± 0,5° before TDC

D 2842 LE 413 16° ± 0,5° before TDC

Injectors

D 2842 LE 401 / 402 / 406 / 408 / 411 five-hole nozzles

D 2842 LE 403 / 412 / 413 six-hole nozzles

Opening pressure of injector

New nozzle holder: 295 + 8 bar

Used nozzle holder: 280 + 8 bar

Engine lubrication Force feed

Oil capacity in oil sump (litres) min. max.

deep 24 l 32 l

semi-shallow 22 l 30 l

for 38 / 45° tilt 37 l45 l

Oil change quantity (with filter)

deep 35 l

semi-shallow 33 l

for 38 / 45° tilt 48 l

Oil pressure during operation (depend-

ing on oil temperature, oil viscosity

class and engine rpm)

must be monitored by oil pressure moni-

tors / gauges

Oil filter Full flow filter with two paper cartridges

Engine cooling system Liquid cooling

Coolant temperature 80−85°C, temporarily 90°C allowed

Coolant filling quantity 96 l

Electrical equipment

Starter 24 V; 6.5 kW

Alternator 28 V; 55, 120, 225 A

Loading...

Loading...