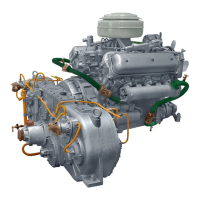

What to do if the Man D 2840 LE 301 starter turns over engine slowly or not at all?

- SSean WigginsAug 5, 2025

If the starter turns the Man Engine over slowly or not at all, check the battery charge and connections. Also inspect the crank gear and clear any blockages. Test the starter solenoid and repair or replace it if necessary. Finally, replace the defective starter or relay.