t

IMPORTANT

t

Operators' attention is drawn to the risks involved in using the forklift truck, in particular:

- Risk of losing control.

- Risk of losing lateral and frontal stability of the forklift truck.

The operator must remain in control of the lift truck. In the event of the lift truck overturning, do not try to leave the cabin during the incident.

YOUR BEST PROTECTION IS TO STAY FASTENED IN THE CABIN.

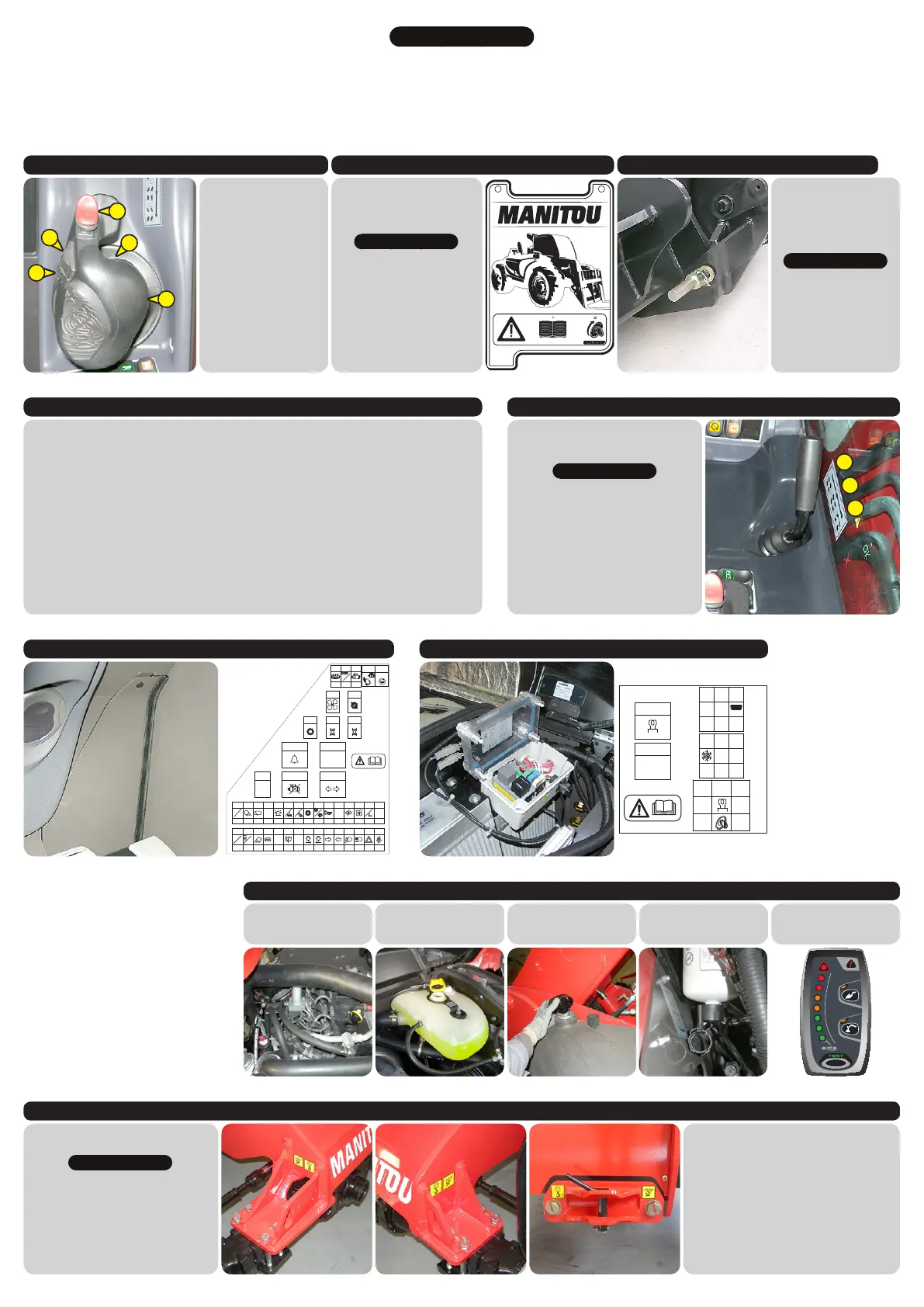

FUSES AND RELAYS IN THE CAB

K5 K6

K9K8

K7

K4K3K2

K1K0

F30F26 F27 F28 F29F16 F17 F18 F19 F20 F21 F22 F23 F24 F25

15A max10A15A max15A 15A max7.5A max 7.5A7.5A 15A7.5A 15A 15A15A 25A7.5A

OPT.OPT.

DIAG

OPT.OPT.

F15F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12 F13 F14

20A25A max20A10A max 7.5A10A15A 7.5A 7.5A max 15A max 5A 10A 15A max15A 10A

OPT.

ECU

HYD.

OPT.

OPT.ECM

N°52505437

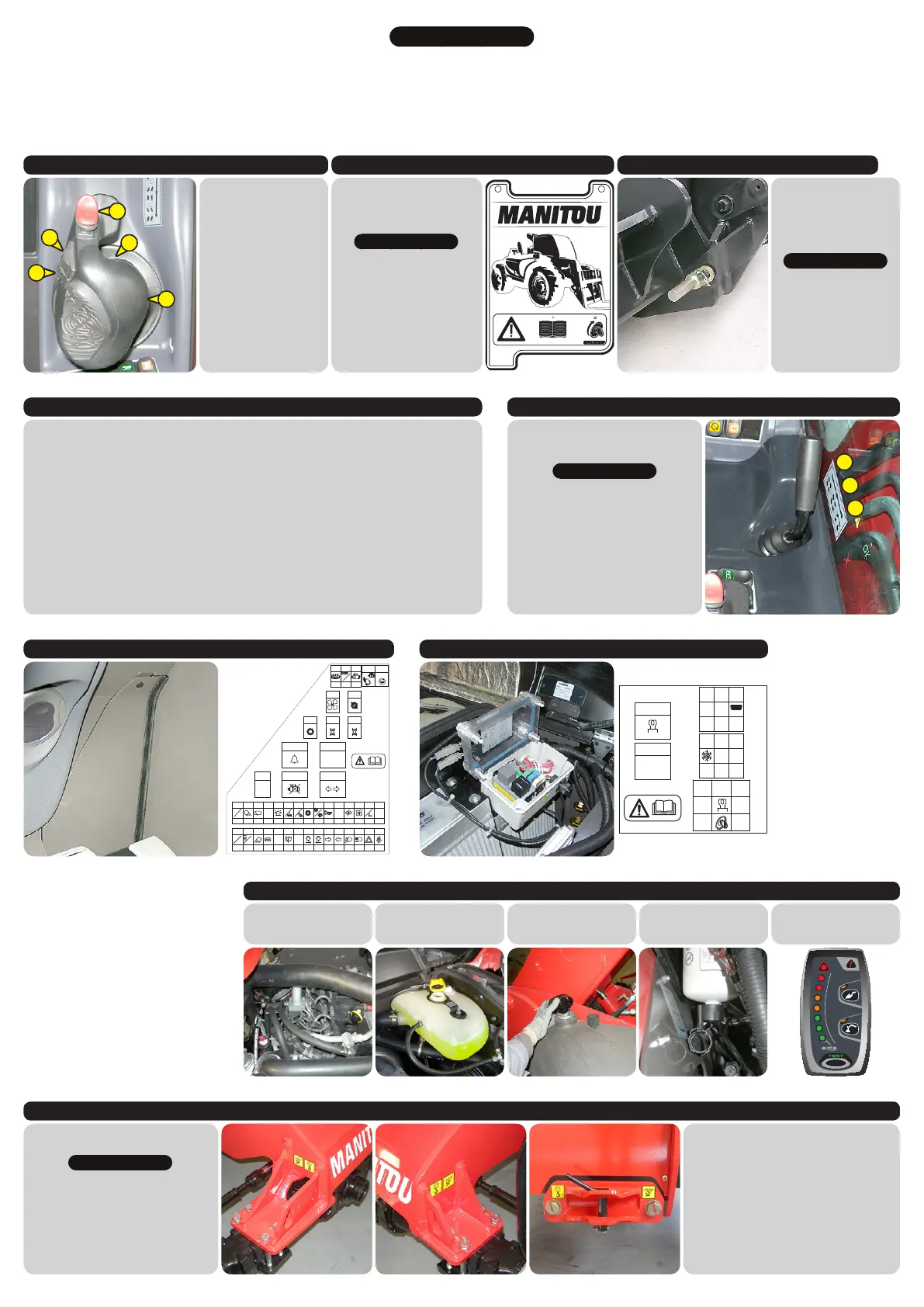

K17K18

STOP

OPT.

OPT.

LSU

OPT.

OPT.

F33 F32 F31

2A 5A 5A

DIAG

SPU

TEST

N

K23

K21

30A

5A

F44

F41F42F43

80AF49

F48

F47

60A

30A

F46 F45

10A

pump

Fuel

N°52505436

Diagn

pump

Fuel

ECM

FUSES AND RELAYS UNDER THE ENGINE BONNET

DAILY MAINTENANCE

CHECK THE ENGINE OIL LEVEL

CHECK THE COOLING

LIQUIDLEVEL

CHECK THE FUEL LEVEL

CHECK THE FUEL PRE-FILTER

CHECK LONGITUDINAL

STABILITY LIMITER AND

WARNING DEVICE

INSTRUCTION SHEETS AND OPTIMAL LOAD CHARTS

t

IMPORTANT

t

See the instruction sheets for use of

the forklift truck.

Comply with the optimal load

charts.

MANUAL ATTACHMENT LOCKING

t

IMPORTANT

t

Before any use, ensure that the

attachment is properly locked.

HYDRAULIC CONTROLS

A - Lifting and tilting control

lever.

B - Telescoping control button.

C - Attachment control button.

D - Head telescope electrovalve

OPTION control button.

E - Forward/neutral/reverse gear

selection

D

E

B

C

A

STOWING THE LIFT TRUCK

t

IMPORTANT

t

Ensure that the safety instructions associated

with the platform are complied with before

loading the lift truck and that the driver of the

carrier vehicle is informed of the dimensions and

the weight of the forklift truck.

STOWING THE LIFT TRUCK

- Fix the chocks to the platform at the front

and at the back of each tire.

- Also fix the chocks to the platform

ontheinside of each tire.

- Secure the lift truck to the platform with

sufficiently strong ropes to the anchoring

points provided.

Authorization to move the lift truck is controlled by an electronic unit. The operator must observe the following sequence

to move the truck forwards or backwards:

• 1 - sit down correctly in the driver’s seat,

• 2 - release the parking brake,

• 3 - engage forward or reverse movement.

NOTE: The alternating display of F/N or R/N on the screen and a rapid, discontinuous beep indicates that the selector needs

to be set to neutral.

To stop the lift truck, he must observe the following sequence:

• 1 - set the forward/reverse selector to neutral,

• 2 - engage the parking brake,

• 3 - get out of the lift truck.

NOTE: A discontinuous beep will inform the driver if he has left the driver's cab without applying the parking brake.

SAFETY FOR MOVING THE FORKLIFT TRUCK STEERING SELECTOR

t

IMPORTANT

t

Never change the steering mode whilst driving.

B1 - Front drive wheels (highway traffic).

B2 - Front and rear drive wheels in opposite direction

(short steering lock).

B3 - Front and rear drive wheels in the same

direction (crab steering).

B3

B1

B2

Loading...

Loading...