National Crane PUBLISHED 04-26-2019 CONTROL # 113-09 5-3

600E2 OPERATOR MANUAL LUBRICATION PROCEDURE AND CHARTS

Protectant available in 12 oz. cans that can be ordered

through the Parts Department.

NOTE: Cylinder operation and inclement weather will

remove the Boeshield protectant. Inspect

machines once a week and reapply Boeshield to

unprotected rods.

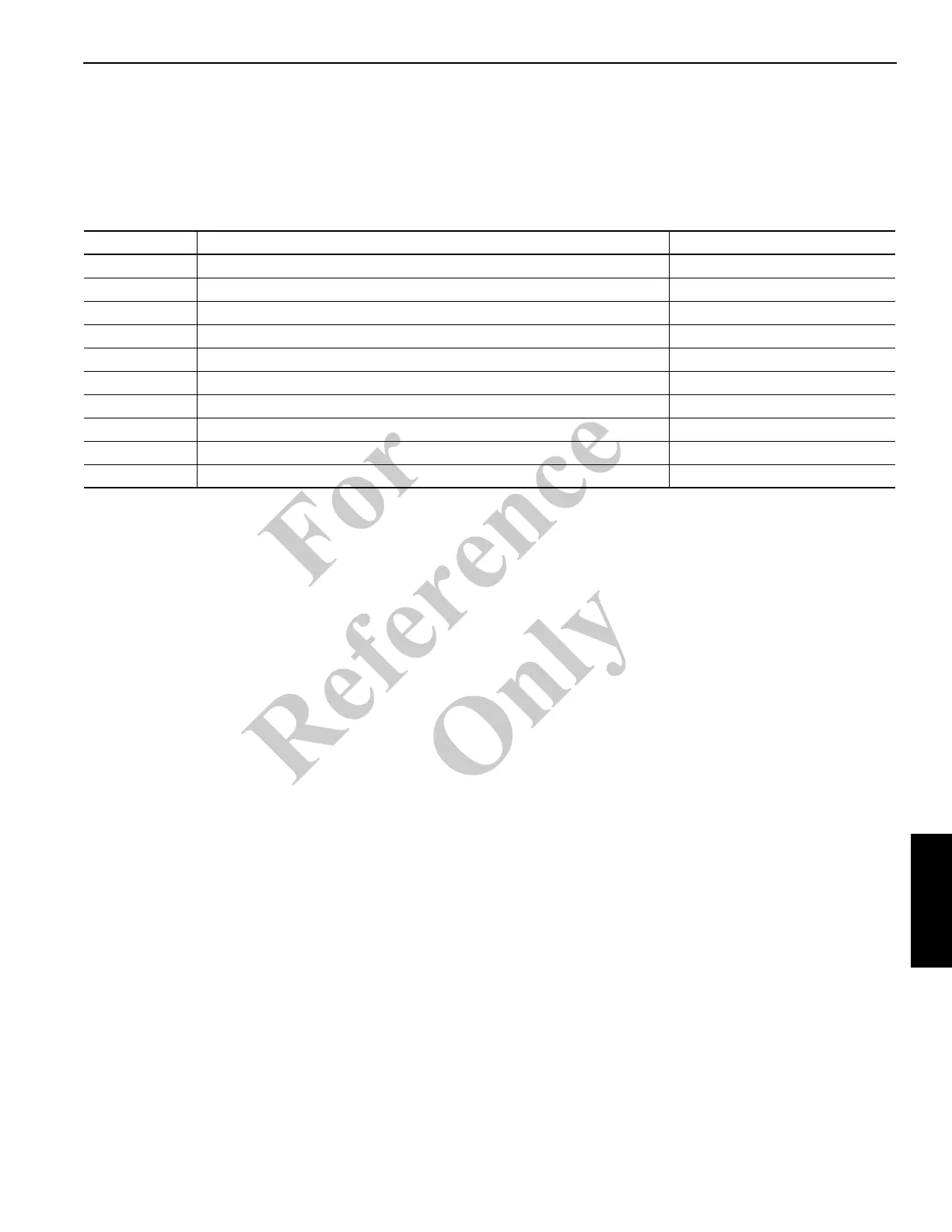

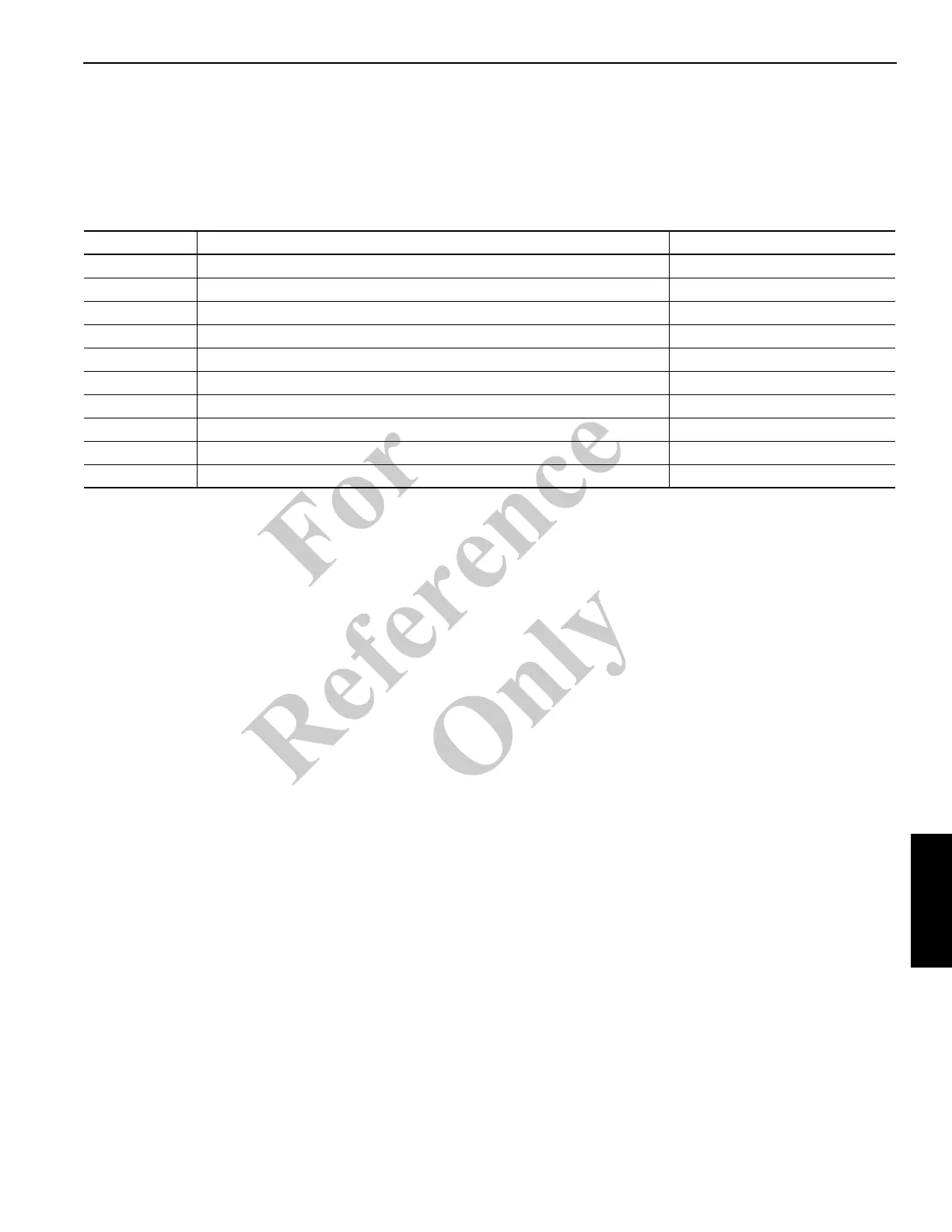

The following describe the lubrication points and gives the

lube type, lube interval, lube amount, and application of

each. Each lubrication point is numbered, and this number

corresponds to the index number shown on the Lubrication

Chart. Lube description and symbols are found in tables

below.

Symbol Description National Crane Lube Specification

EP-MPG Extreme Pressure Multipurpose Grease - Lithium Soap Base, NLGI Grade 2. A6-829-003477

EP-3MG Extreme Pressure Moly Grease A6-829-015304

GL-5 Extended Service Interval Gear Lubricant - SAE Grade 80W-90 A6-829-012964

AFC - 50/50 50/50 Blended Fully Formulated Antifreeze/Coolant, SAE J1941, ASTM D6210 A6-829-101130

HYDO Hydraulic Oil - Must meet ISO 4406 cleanliness level 17/14 A6-829-006444

EO-15W/40 Engine Oil - SAE 15W-40, API Service Classification CI-4 or better A6-829-003483

EP-OGL Open Gear Lubricant, CEPLATTYN 300 Spray, NLGI Grade 1-2 A6-829-102971

AGMA EP-4 Extreme Pressure Gear Lubricant. A6-829-100213

WRL Wire Rope Lubricant A6-829-015236

LTG Low Temperature Grease, NLGI Grade 1 A6-829-225828

Fo

r

Reference

Only

Loading...

Loading...