National Crane Published 4-23-2018 Control # 239-11 4-5

NBT40 SERIES OPERATOR MANUAL SET-UP

14. Using boom telescope function, slowly retract boom.

The jib stow bracket (H, Figure 4-1) on the side of the jib

will engage the side stow bracket (D) on the side of the

1

st

section boom; first lifting the jib and then engaging

the jib side stow bracket (H) and the stow bracket (D)

completely upon full retraction of the boom.

15. Install stow pin (A, Figure 4-1) with spring clip into the jib

stow bracket (H) on the jib. Complete engagement of

stow brackets and proper installation of pin A is critical

for secure jib stow attachment.

16. Remove pins (C1 Figure 4-1) from upper and lower jib

ears. A slight hammer strike may be necessary to

remove pins. Always use proper eye protection during

this step.

17. Reinstall loadline over boom sheave case.

JIB REMOVAL

Should jib removal from the boom become necessary,

proceed as follows:

1. Unstow and swing jib into position on the boom tip

according to Steps 1 - 10 in the preceding jib deployment

section.

2. Support and raise the jib at its balance point and remove

the two swing around pins. Jib is now free of boom.

3. To install, proceed in reverse order of removal.

When the jib is stowed on side of crane, always leave the

ram and handle sleeve of the jib jack pushed all the way

down to reduce exposure to rusting.

Jib Maintenance

1. Lubricate as outlined in SECTION 5.

2. Check for free rotation of jib sheave daily when using jib.

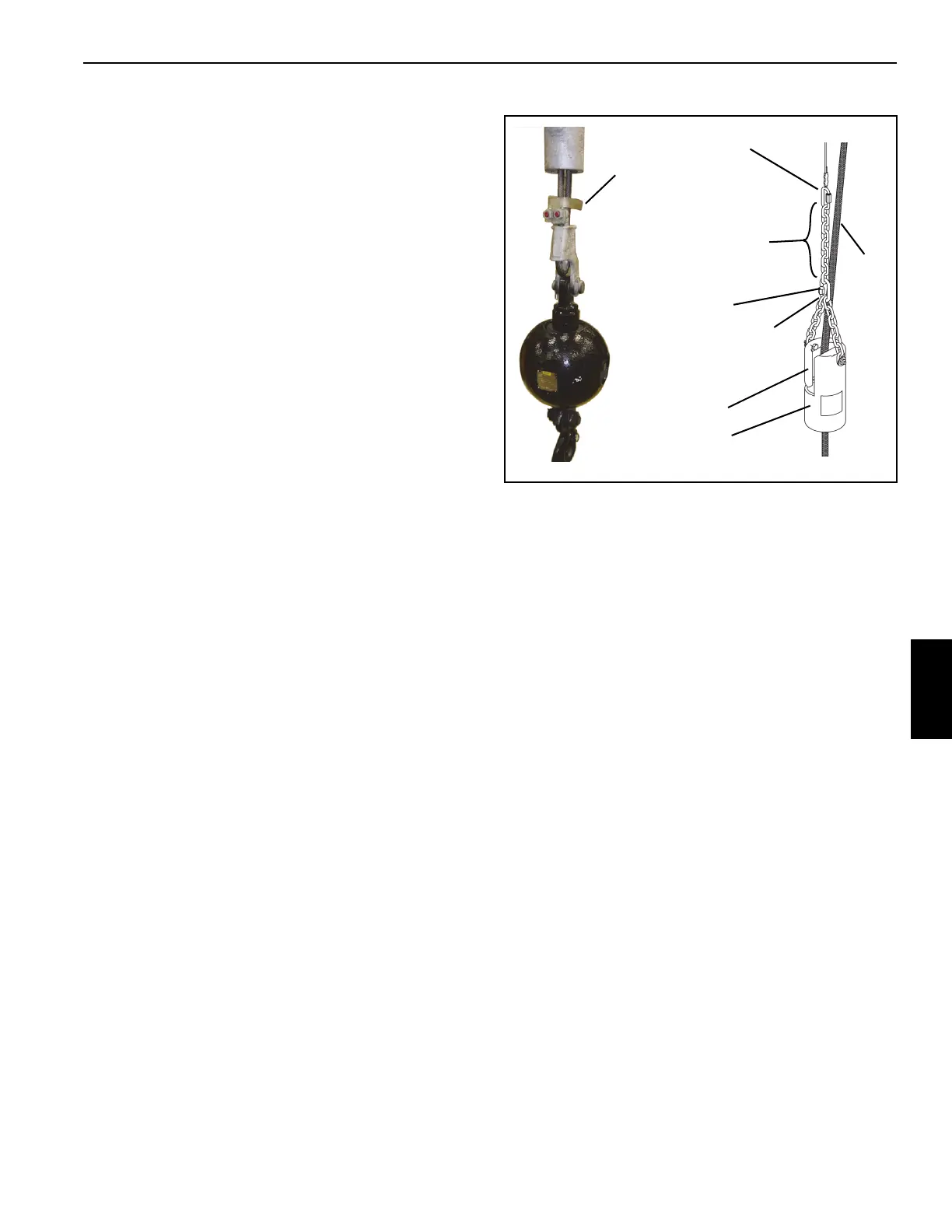

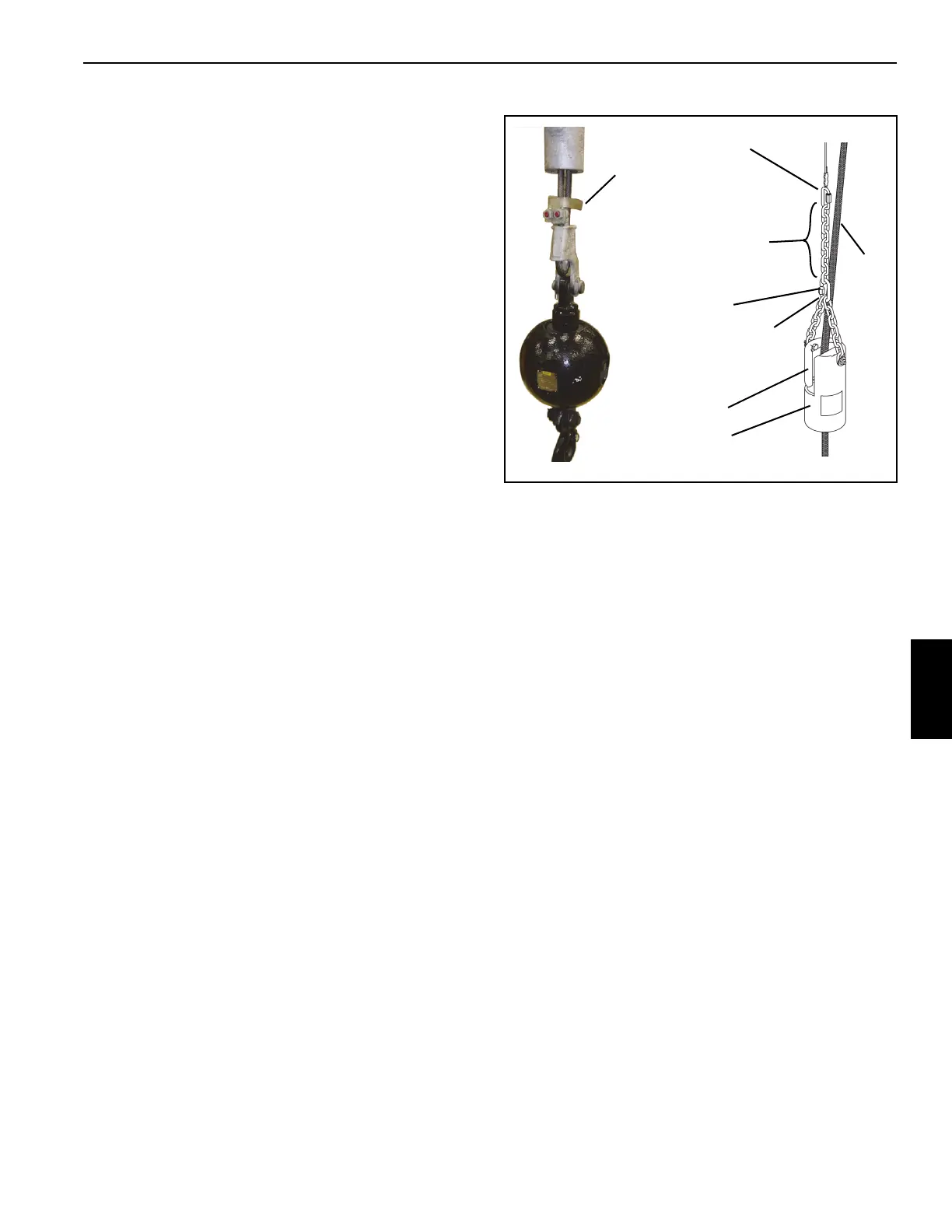

ANTI-TWO BLOCK WEIGHT INSTALLATION

To prevent the hoist cable from slipping out of the ant-two-

block weight, rig the weight as shown in Figure 4-2.

The A2B bracket is for single part line use only. Remove the

A2B bracket shown in Figure 4-2 from the hoist cable when

changing from a single part line to a multiple part line to allow

the hoist cable and wedge socket to reeve through the

sheaves on the boom nose and the hookblock. Re-install the

clamp and nuts to the cable before performing a lift.

MULTI-PART LINE REEVING

Multi-part line reeving enables greater loads to be lifted than

can be lifted with single part line. However, loads are limited

by the stability and structural integrity of the crane. The load

must be within the limits contained in the load chart.

Using Multiple Part Lines

The hoist data chart provides information for pull limitations

on the hoist with various multipart reevings. These ratings

are based on providing the proper operating safety factor on

the cable supplied with the crane. Therefore, any

replacement rope must meet the cable specification in this

manual.

The A2B bracket is for single part line use only. Remove the

A2B bracket shown in Figure 4-2 from the hoist cable when

changing from a single part line to a multiple part line to allow

the hoist cable and wedge socket to reeve through the

sheaves on the boom nose and the hookblock. Re-install the

clamp and nuts to the cable before performing a lift.

STOW PEGS FOR HOIST CABLE

Stow pegs located on top of the boom keep the hoist cables

secure when not reeved over the boom nose. The main hoist

cable is stowed on the right peg and the auxiliary hoist cable

is stowed on the left peg as viewed from the back of the

boom.

FIGURE 4-2

The anti-two-block chain

must be installed

between the slot in the

weight and the hoist

cable.

Anti-two Block

Weight

Hoist

Cable

Slot

Chain Length 40 cm

(16 inches) Do not

shorten the chain.

Upper Link

Lower Link

The A2B bracket must be

removed from the hoist

cable when reeving for

multi-part line.

8835

Loading...

Loading...