45

NOTE: With a view of observance of hygienic conditions and eciency optimisation

the backwashing must be carried out no matter how long the operation time is or

pressure load increase at least each 8 days due to hygienic reasons. If the pressure

load grows, the backwashing must be performed more frequently.

Change of sand fill

Absorption capacity of sand ll to capture impurities completely rests in coarseness

of sand particular grains which are gradually brushed during the ltering.

In order to maintain maximum ltering eect we recommend to change the sand

ll before each or every second season.

Cleaning of pump preliminary filter.

• Switch the pump motor o (disconnect the plug from socket).

• Close the stop-cocks. *

• Unscrew the ring with thread and remove the clear small window Remove the

cover of coarse preliminary lter, clean and put it back. Put the clear small window

back and screw and tighten the ring with thread.

• Open the stop-cocks.

• Connect and switch the pump motor.

ATTENTION: The pump motor must not be operated without the screen of coarse

preliminary lter, otherwise it could be clogged and blocked.

* If the stop-cocks are not used, water will ow our of the pump open suction.

Troubleshooting

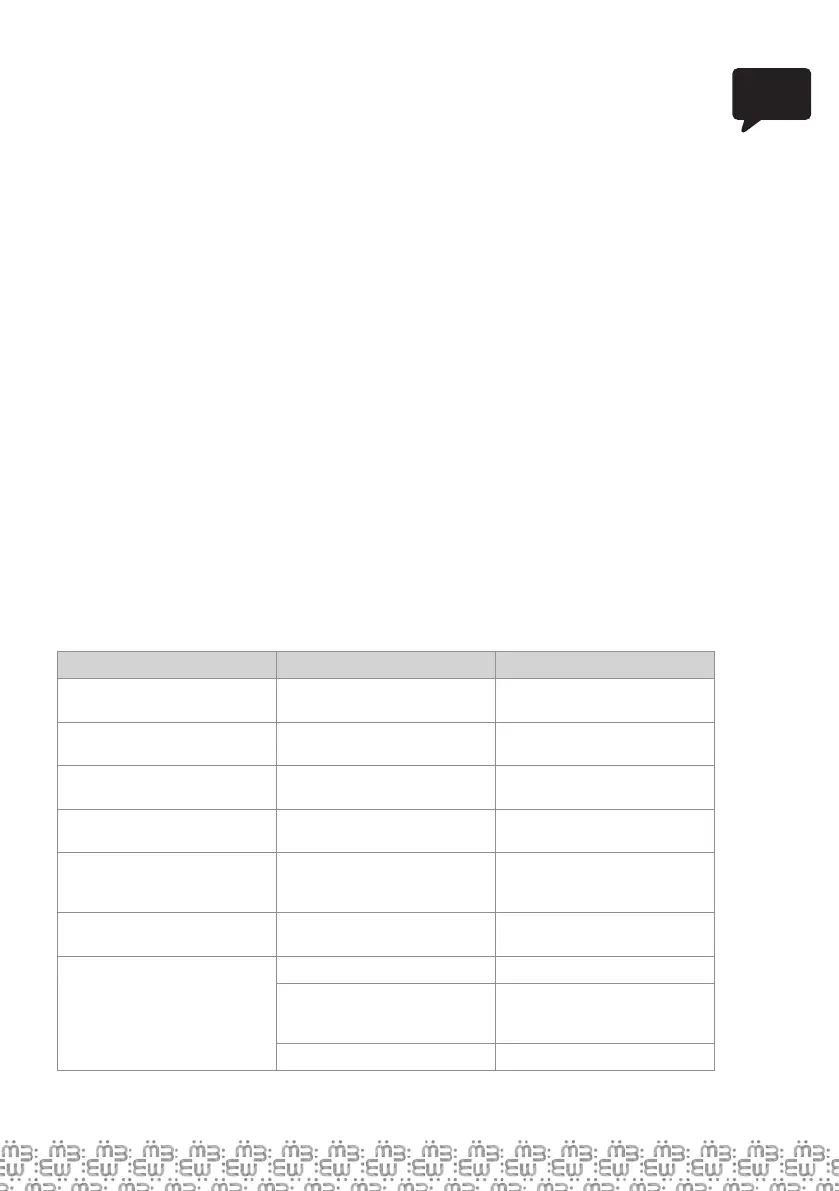

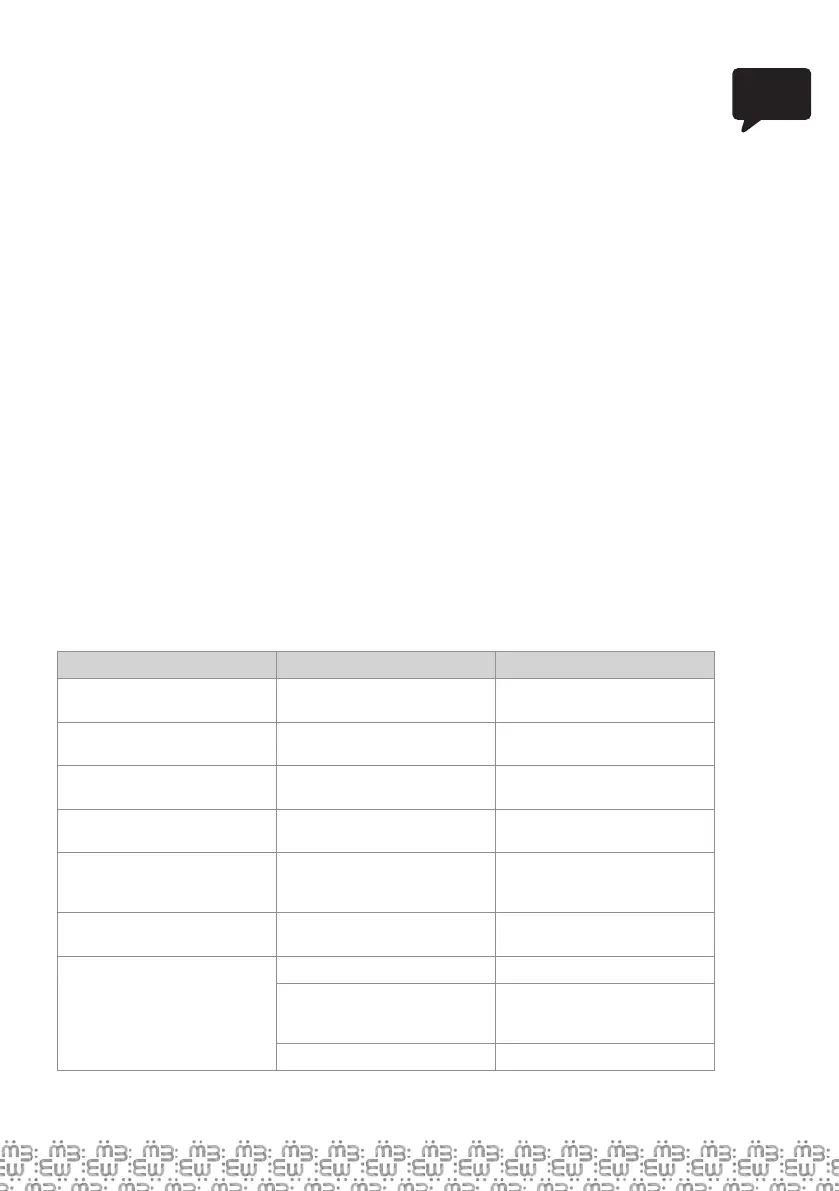

DEFECT CAUSE SOLUTION

Pressure gauge shows higher

pressure than 1 bar.

Clogged sand ll.

Carry out then backwashing

operation.

Too low pressure

Clogged screen of pump coarse

preliminary lter.

Clean the coarse preliminary

lter screen.

Air lock in coarse preliminary

lter.

Leaks at suction side.

Tighten hose clamps and PVC

joints.

Water outow from waste

socket.

This means that valve seating

faces are damaged.

Have the valve repaired.

Water ows to the waste.

Impurities around the sealing of

six-way valve.

Unscrew the six-way valve from

the ltration vessel lid and

clean the sealing.

Filtration vessel leakage. Defective sealing.

Check the sealing and change it

if it is necessary.

Motor of the pump does not

run.

The plug is out of the socket. Put the plug in the socket.

Tripped earth-leakage circuit

breaker.

Switch the earth-leakage circuit

breaker, if it immediately trip

again, the pump motor is

Defective motor of the pump. Change the motor.

EN

Loading...

Loading...