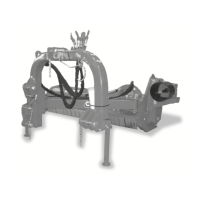

The device described in the manual is a professional folding rotary tiller, referred to as PANTERA. It is designed for farm contractors and large agricultural enterprises, offering high standards of productivity and reliability, combined with easy and safe road transportation.

Function Description

The PANTERA rotary tiller is primarily used for soil cultivation, aiming to achieve a finely refined and leveled seedbed with uniform clod dimensions. Its robust structure and mechanical design ensure consistent performance over time. The effective mixing of the soil, combined with significant pulverization, allows for excellent incorporation of surface residues and optimal control of annual weeds. The resulting seedbed is suitable for various crops, especially when high precision in seed placement is required.

This agricultural equipment operates exclusively via a Cardan shaft connected to the power take-off (PTO) of an agricultural tractor equipped with a three-point universal hitch and a lifting unit.

Important Technical Specifications

The PANTERA is available in five working widths to match tractors ranging from 200 to 380 HP:

- PANTERA 420: 428 cm (168 inch) working width, 458 cm (180 inch) transport width, 214 cm (83 inch) height, 147-280 kW (200-380 HP) power requirement, 96 blades, 2870 kg (6327 lb) weight without roller.

- PANTERA 470: 478 cm (188 inch) working width, 505 cm (199 inch) transport width, 239 cm (94 inch) height, 160-280 kW (220-380 HP) power requirement, 108 blades, 3015 kg (6647 lb) weight without roller.

- PANTERA 520: 528 cm (208 inch) working width, 558 cm (220 inch) transport width, 264 cm (104 inch) height, 176-280 kW (240-380 HP) power requirement, 120 blades, 3330 kg (7341 lb) weight without roller.

- PANTERA 570: 578 cm (228 inch) working width, 608 cm (240 inch) transport width, 289 cm (114 inch) height, 190-280 kW (260-380 HP) power requirement, 132 blades, 3420 kg (7540 lb) weight without roller.

- PANTERA 620: 628 cm (247 inch) working width, 660 cm (260 inch) transport width, 314 cm (124 inch) height, 205-280 kW (280-380 HP) power requirement, 144 blades, 3695 kg (8146 lb) weight without roller.

The maximum weight permitted with accessories is 5000 kg (11023 lb). To calculate the machine's weight with a roller, the roller's weight (x2) must be added to the weight of the rotary tiller without the roller.

Sound Level (UNI EN ISO 4254-1:2010):

- Sound pressure level (LpAm): 81.1 dB (A)

- Sound power level (LwA): 97.8 dB (A)

Rollers Weight (Kg/Lb):

- Packer Roller:

- Ø 500: 345-478 kg (760-1053 lb) depending on model.

- Ø 600: 438-605 kg (965-1333 lb) depending on model.

- Spiral Roller:

- Ø 500: 246-333 kg (542-734 lb) depending on model.

- Cage Roller:

- Ø 450: 210-284 kg (463-626 lb) depending on model.

- Spiked Roller:

- Ø 600: 228-309 kg (502-681 lb) depending on model.

Each model requires two rollers.

Usage Features

The PANTERA is intended for professional use only, to be operated by trained, authorized personnel holding a valid driving license. The recommended working speed is 6-8 km/h. Road transportation must not exceed 25 km/h. Any use outside these specifications can damage the machine and pose serious risks to the user.

Attachment to the Tractor:

- Hook the lifter bars onto the provided pins, blocking them with snap split pins and attaching chains.

- Connect the upper third point, ensuring the pin is blocked and using the adjusting tierod to keep the machine perpendicular to the ground.

- Block the movement of the tractor's parallels on the horizontal plane using stabilizers to eliminate side swaying.

- Connect hydraulic pipes correctly, following instructions on each pipe.

- Connect the Cardan shaft, ensuring it is perfectly blocked on the PTO and its guard turns freely, secured by a chain.

Hydraulic System:

The machine's hydraulic system allows for various movements, including opening/closing the transmission units (for working/transport positions) and adjusting the rear rollers for working depth. The cylinders for closing the hitches are controlled in sequence with the body control cylinders and do not require a specific command. Hydraulic pipes are color-coded for function recognition (e.g., rear roller lowering/lifting, lateral body closing/opening). Maximum pressure for all pipes is 180 bar (1/4").

Work Depth Adjustment:

Working depth is determined by the position of the leveling rollers, skids, or optional rear wheels.

Rollers:

- Packer Roller (Ø 500, Ø 600): Effective in varied conditions, including heavy and damp soils. Recommended for heavy soils and seedbed preparation in combination with a seed drill. Provides excellent leveling and crumbling effects both on the surface and at depth.

- Spiropacker Roller (Ø 500): Features a spiral bar wrapped around a central shaft. Ideal for light, sandy soils, leaving some clods on the surface and settling the ground at depth, creating a suitable seedbed for seed drills.

- Cage Roller (Ø 450): Used in medium-textured, not excessively damp soils. Controls tilling depth, levels the soil, refines the seedbed, and improves preparation.

- Spiked Roller (Ø 600): Equipped with long, shaped teeth (4 per work section, 250 mm pitch). Suitable for all soil types and conditions. Does not compact the soil, leaving it aerated and leveled. Primarily used for preparing already ploughed soil at depth.

Double Rear Bonnets (Leveling Plates):

Offer various adjustments for optimal results in all ground conditions. A new system allows adjustment via mechanical jacks with a graduated rod. Lifting the bonnets results in less refining and leveling (recommended for wet soils), while lowering them provides more refining and leveling (recommended for dry soils) but increases power consumption. Adjust based on soil type and desired outcome.

Conveyors:

Retain soil within the rotary hoes' chamber for better working and to prevent accumulation at the machine's sides. They also act as protection, closing the gap between leveling plates and the external side, and support roller connections when the machine is in the closed position.

Hoe Blades:

Made of high-quality steel with heat treatments for toughness and wear resistance. Curved and/or square blades can be fitted based on soil characteristics. Normally equipped with 6 blades per flange. Bolts fixing the blades must have their heads on the blade side, with the nut and washer on the flange side.

Working Practices:

- Start work with the PTO at running rate, gradually lowering the machine into the soil.

- Avoid excessive accelerator pressure with PTO engaged.

- Soil pulverization depends on soil type, working depth, tractor forward speed, and optimal machine adjustment.

- Slow forward speed and lowered leveling blade result in finer soil.

- Raised leveling blade leads to coarser soil and less smooth finish.

- Do not exceed 8 km/h working speed to prevent damage.

- Never operate the machine out of the soil.

- Avoid turning corners or working in reverse with the implement in the soil.

- Always raise the implement for reversing or changing direction.

- For transport, adjust the tractor's lift unit so the implement is not raised more than 35 cm from the ground.

- Do not drive on public roads with a dirty machine.

- Lower the machine slowly to allow gradual blade penetration, avoiding violent drops that could stress components.

Troubleshooting (Common Issues):

- Insufficient depth: Adjust skids/roller, reduce forward speed, make additional passes on hard soil, or check blade penetration.

- Excessive pulverization: Raise leveling blade, increase forward speed.

- Insufficient pulverization: Lower leveling blade, reduce forward speed, avoid working in very wet soil, or adjust leveling bar.

- Rotor clogging: Due to very wet soil, high ground speed, high grass, or worn blades. Remedies include raising leveling blade, reducing ground speed, reducing blade count per flange, or cleaning supports.

- Machine bouncing/vibrating: Caused by foreign bodies, incorrect blade assembly, worn/broken blades, warped rotor, or incorrect Cardan shaft position. Remedies include freeing rotor, correct blade assembly, replacing blades/rotor, or lowering leveling plates.

- Uneven working depth: Adjust depth skids/roller or lower lifting links.

Maintenance Features

Maintenance operations should be performed by skilled personnel using appropriate PPE (safety footwear, overalls, gloves) in a clean, dust-free environment. The machine must be hooked to the tractor, parking brake engaged, engine off, ignition key removed, and equipment resting on suitable supports.

Scheduled Maintenance Plan:

- When New: Grease all indicated points, lubricate transmission chains with mineral oil (SAE 80W/90), and check bolt tightness after initial hours.

- Every 8 Working Hours: Grease Cardan shaft cross journals, check hoe blade bolts, and grease roller supports (if installed).

- Every 50 Working Hours: Change oil in the gearbox housing. Check oil levels in gearbox and rotor spindle cover, topping up as needed. Grease Cardan shaft cross journals. Check and top up oil in side transmission gears.

- Every 400 Working Hours: Change oil in gearbox and transmission casing by draining old oil. Demount and clean clutch disks, check clutch spring tightness (if applicable). Check all bolt tightness.

- Every Five Years: Replace all hydraulic system tubes.

- Rest Period (End of Season/Long Storage):

- Thoroughly wash and dry the equipment, especially chemical substance hoppers.

- Check for worn/damaged parts and replace as needed.

- Firmly tighten all screws and bolts.

- Apply protective oil to unpainted parts.

- Protect the equipment with a cover.

- Position it stably in a dry place, out of reach of unauthorized persons.

Oil Quantities (I.):

- Gearbox: 6.00 l

- Rotor spindle cover: 0.65 l

- Side transmission casing: 6.00 l

Hydraulic Systems Maintenance:

- Only skilled operators should maintain hydraulic systems.

- Hydraulic system is under high pressure; use special auxiliary instruments for leak detection.

- To unload hydraulic pressure, operate all hydraulic controls multiple times after turning off the engine.

- High-pressure oil leaks can cause skin injuries; seek immediate medical attention.

- Never install hydraulic components in the tractor cab.

- Carefully position all system components to prevent damage.

- Check hydraulic pipes for wear at least once a year.

- Replace damaged or worn pipes.

- Replace all hydraulic pipes every 5 years, even if unused.

- Before starting, ensure hydraulic pipes are correctly connected, positioned, and free to move. Replace any damaged parts.

Cleaning:

- Dispose of cleaning products according to regulations.

- Clean and maintain the machine after replacing any removed guards.

- Clean electrical components with a dry cloth.

- When using pressurized cleaning systems, maintain a minimum distance of 30 cm from surfaces, especially bearings.

- Thoroughly lubricate after pressurized cleaning.

Demolition and Disposal:

- To be carried out by the customer.

- Before demolition, check the machine's physical condition for structural collapse or breakage risks.

- Operate in compliance with local environmental protection laws.

- Demolition must be performed by qualified personnel using appropriate PPE and auxiliary tools.

- All disassembly operations must be done with the machine stopped and detached from the tractor.

- Render all dangerous parts harmless: scrap the structure via specialized firms, remove electrical apparatus according to laws, and separately collect oils and greases for disposal by authorized firms.

- Destroy the CE mark along with the manual during demolition.