Do you have a question about the Maschio PITAGORA INLINE and is the answer not in the manual?

Explains the purpose and function of baling machines and the process of baling.

Details the specific applications and allowed materials for the PITAGORA INLINE baler.

Provides general details and validity of the user manual.

Mentions the company's quality management system certification.

Specifies details needed when contacting for support or parts.

Reiterates the intended agricultural use and restrictions.

Discusses environmental considerations and safe disposal practices for chemicals.

Outlines the necessary tractor specifications like power and PTO speed.

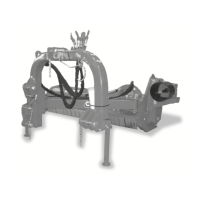

Presents detailed technical specifications of the baler in a table format.

Emphasizes the importance of reading and obeying safety rules in the manual.

Explains danger, warning, and caution terms and their associated colors.

Stresses the importance of caution, training, and adherence to warnings for accident prevention.

Details requirements for operators, maintenance, and repair personnel.

Lists potential dangers and consequences of not following safety measures.

Advises on complying with safety measures and traffic rules.

Provides general safety rules for operation and equipment handling.

Focuses on checking mechanical systems to prevent jams and foreign objects.

Details safe procedures for connecting and disconnecting PTO shafts.

Warns about hydraulic system pressure and safe connection practices.

Advises on safety measures when working on tires.

Lists essential safety steps to follow during maintenance and repair.

Shows pictograms and their meanings for machine-specific safety warnings.

Identifies hazardous areas around the machine during operation and specifies safe approach distances.

Lists checks to perform before initial operation and daily checks.

Explains the procedure for connecting the drawbar to the tractor.

Describes how to connect, release, and adjust the jack system.

Details the steps to transition the machine from road/drive to work position.

Explains how to connect the PTO shaft to the baler, including safety precautions.

Guides on connecting hydraulic hoses between the tractor and the baler.

Provides instructions for connecting the electrical system of the baler to the tractor.

Illustrates the process of installing twine coils and threading them into the needles.

Explains how to adjust settings for bale density, weight, and size.

Details the adjustment procedure for the front flywheel tripod clutch lining.

Covers the installation and tensioning of various chains within the collection unit.

Describes how to adjust the height and settings of the pick-up unit and its components.

Explains the adjustments for auger settings to prevent crop jamming and ensure smooth flow.

Outlines procedures for adjustments after transmission chain breaks or related component failures.

Details the adjustments required after a knotter set drive chain breaks.

Provides instructions for replacing shear bolts in different units of the machine.

Explains the procedure for adjusting piston bearings, rails, and blades.

Describes how to adjust the length of the needle saddle lever.

Details the adjustment and maintenance of the safety latch system.

Explains the adjustment of compression springs for needle saddle lining.

Covers adjustments for the knotter set and troubleshooting the twine pulling mechanism.

Provides instructions for adjusting the needles for different knotter set types.

Gives guidance on preparing the machine for winter storage and general maintenance.

Details daily lubrication requirements for shaft joints, clutches, and housings.

Specifies weekly lubrication for the jack system.

Outlines lubrication frequency for the drawbar based on operation time.

Details lubrication frequency for the star unit based on operation time.

Specifies daily lubrication for the flywheel and related components.

Covers daily lubrication of knotter set components due to continuous motion.

Details daily lubrication for the ratchet unit.

Specifies daily lubrication for hayfork bearings and units.

Provides guidance on chain lubrication, recommending oil instead of grease.

Explains the type of oil and frequency for transmission oil changes.

Lists common problems related to the PTO shaft area and their solutions.

Addresses problems and solutions for the collector area of the baler.

Details issues and remedies concerning the feeder area, specifically bale form.

Presents the electrical schematic for the PITAGORA INLINE Baler.

Illustrates the hydraulic circuit diagram for the baler.

Lists circumstances and components that are not covered by the warranty.

| Brand | Maschio |

|---|---|

| Model | PITAGORA INLINE |

| Category | Farm Equipment |

| Language | English |