Flushing Procedure:

Flushing frequency: weekly, preferably at the end of a workday, more often if carry-over from traps

contaminate the pump.

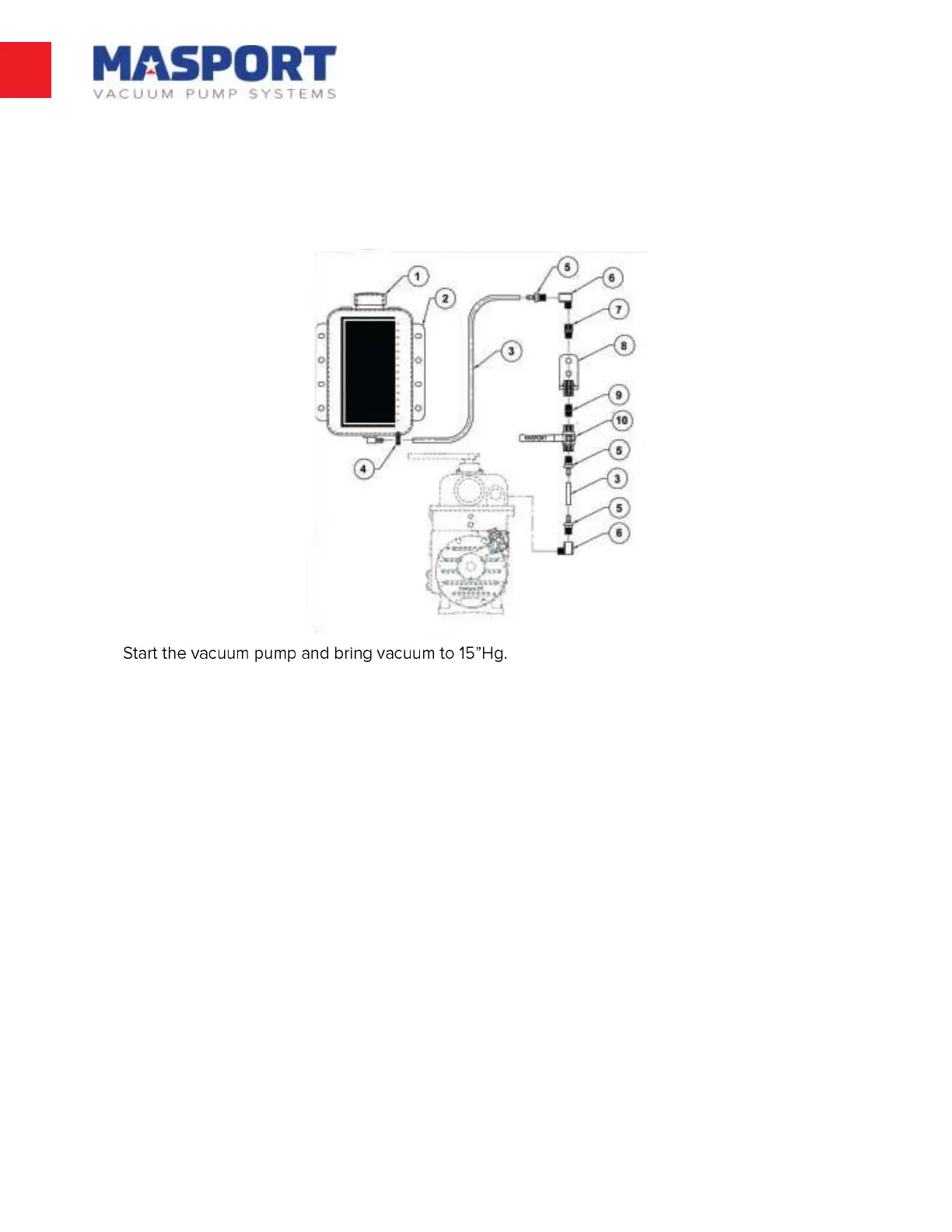

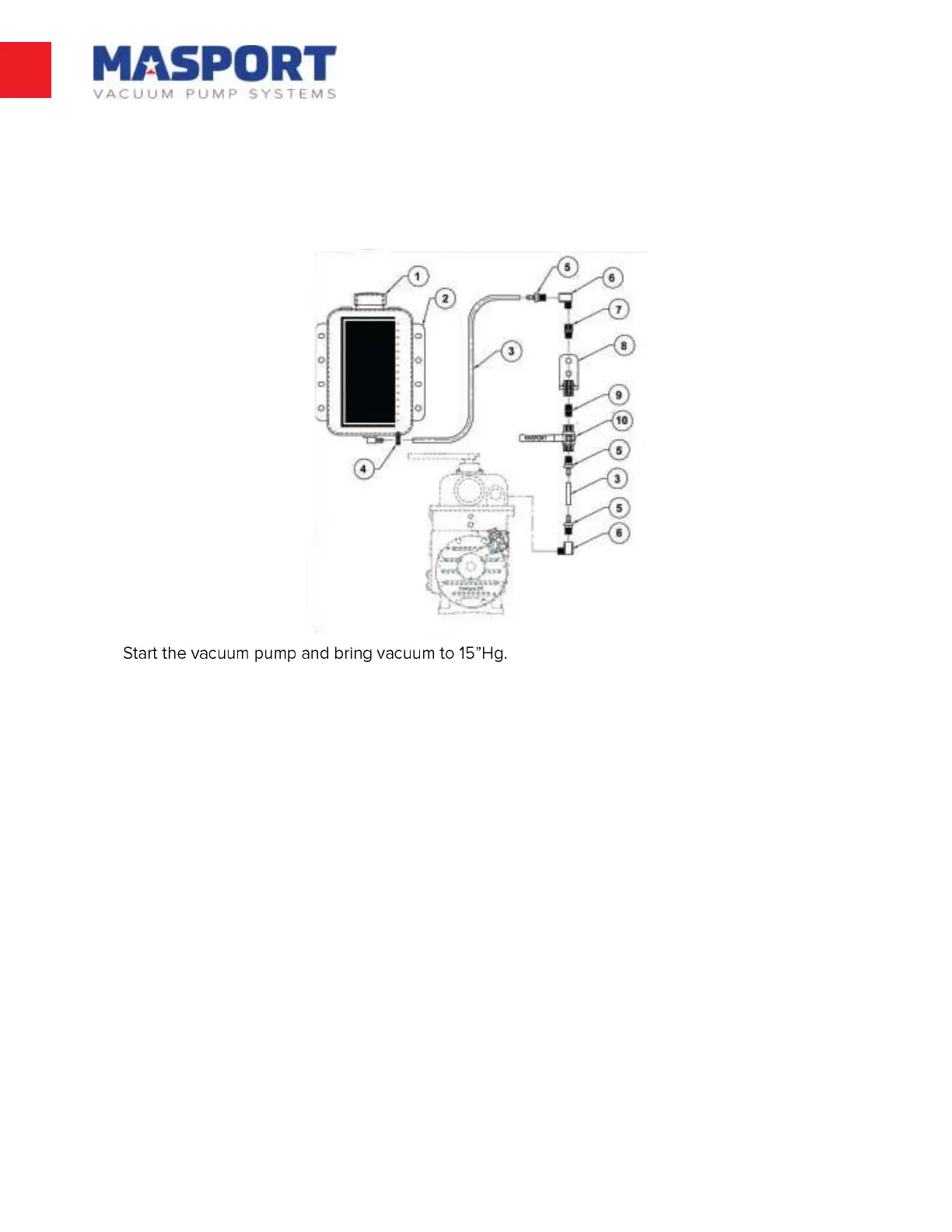

Connect the Flushing Kit to the flushing port on the Masport vacuum pump

Open the ball valve to begin flushing fluid flow.

Continue to run the pump until the fluid level drops 1 graduation (approximately 7 fluid ounces).

Close the ball valve.

Continue to operate the pump for 3 additional minutes to ensure all fluid is purged from the

pump.

Stop the vacuum pump.

Drain the oil separator and dispose of used fluid at an approved recycling site.

Maintenance and Important Operating Tips

To keep the pump in a workable condition operators should undertake regular maintenance and

keep a written log of those checks.

Before Starting:

Ensure a vacuum relief valve and a pressure relief valve are installed in the system and adjusted

to recommended settings, taking into account the altitude of the job location.

Always bleed the tank to atmospheric pressure before switching the valve from vacuum to

pressure or from pressure to vacuum.

Loading...

Loading...