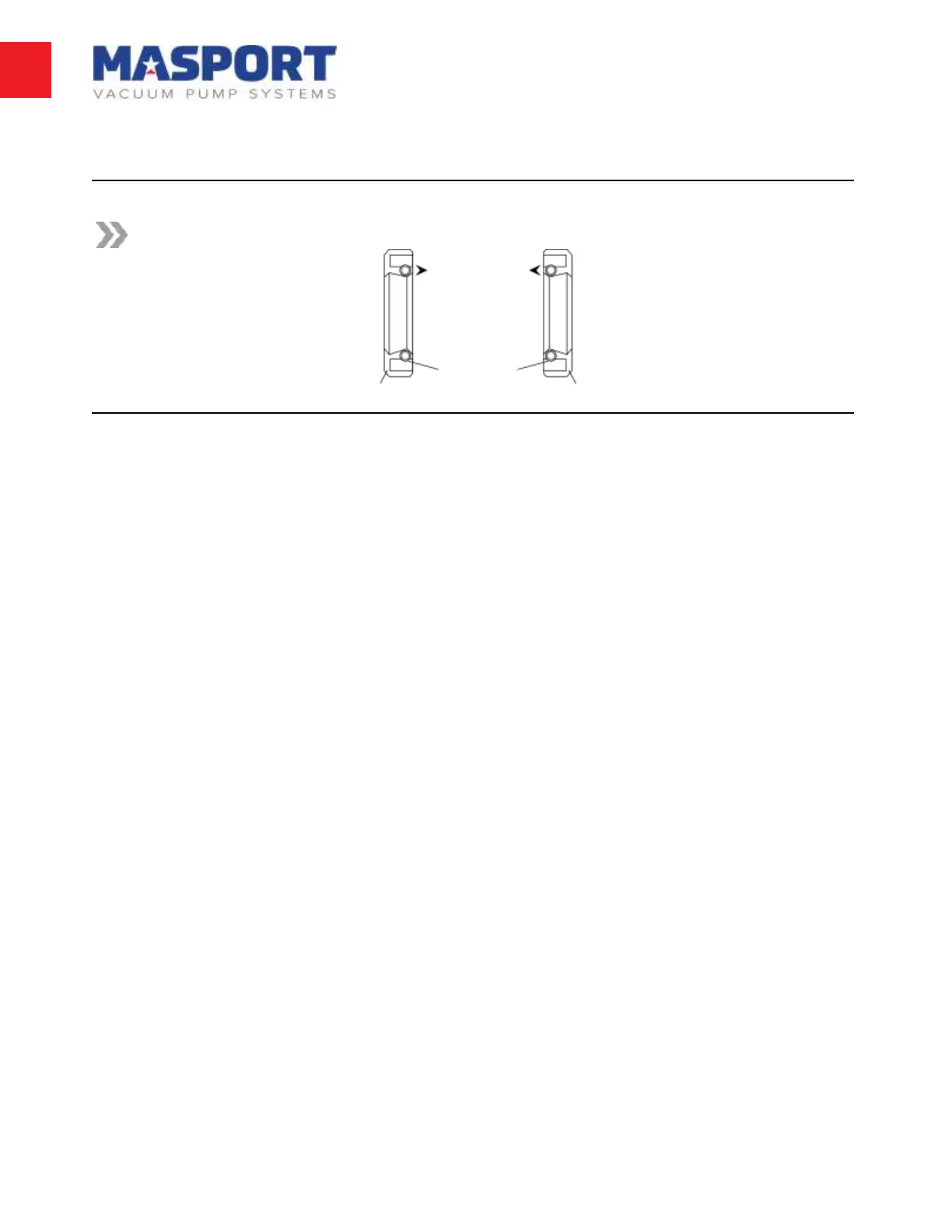

Place the new oil seal in the seal housing. Ensure that the oil seal is installed with the spring side of

the seal facing into the bearing bore of the end cover.

Note: Incorrect installation of the oil seal will potentially result in oil leaks around the shaft

and bearing failure.

The oil seal should be pressed into the seal bore on the end cover using a seal press or a flat round

disc approximately the same outside diameter as the oil seal. Care must be taken to press the oil

seal into the bore evenly to prevent damage.

Reassembly:

The area to be used for reassembly should be thoroughly cleaned to prevent contamination during

the reassembly process.

Installing the First End Cover

If both end covers have been removed from the cylinder the below procedure needs to be followed.

Spread a small amount of oil around the cylinder face to hold the end cover Shim Gaskets in place.

Place the new end cover Shim Gaskets (the correct quantity and color that were removed during the

disassembly process) over the dowel pins and onto the oiled face of the cylinder.

Where used, install the O-Ring in the end cover groove. Small dabs of grease will help retain the O-

Ring in the groove.

Align the end cover dowel pin holes with the dowel pins in the cylinder face. Drive the cover on

evenly with a rubber mallet working from side-to-side to prevent bending the dowel pins or

distorting the holes in the end cover.

Install the end cover retaining bolts and torque them to 29-30 ft/lbs. When tightening work across

the cover, alternating from one side to the other to ensure even pressure.

Apply a small amount of grease to the lip of the oil seal.

Installing the Rotor Assembly:

Spread vacuum pump oil around the cylinder bore to avoid damage to the rotor and cylinder bore

when refitting the rotor.

For HXL Series pumps, reinstall the worm gear for the oil pump drive and tighten the set screw.

Loading...

Loading...