If the seal gap clearance needs to be reset the following technique can be used.

Note: In order to reset the seal gap clearance the dowel pins on the inlet side on both

ends of the cylinder need to be removed.

Place the correct sized feeler gauges in position in the cylinder

Turn the pump upside down. For this to be possible the valve assembly will need to be

removed to allow the cylinder to rest flat.

Loosen the end cover bolts on both end covers

Allow the end covers to pivot on the cylinders exhaust side dowel pins bringing the rotor into

contact with the feeler gauges.

Re-torque the end cover bolts evenly on both end covers

Turn the pump over and re-check the seal gap clearance. Repeat the process if the seal gap

clearance is still out of specification.

If within specification drill and ream to fit either new oversized dowel pins or to reposition the

original dowels pin.

Clear swarf from the drilled holes and fit the dowel pins to secure the setting.

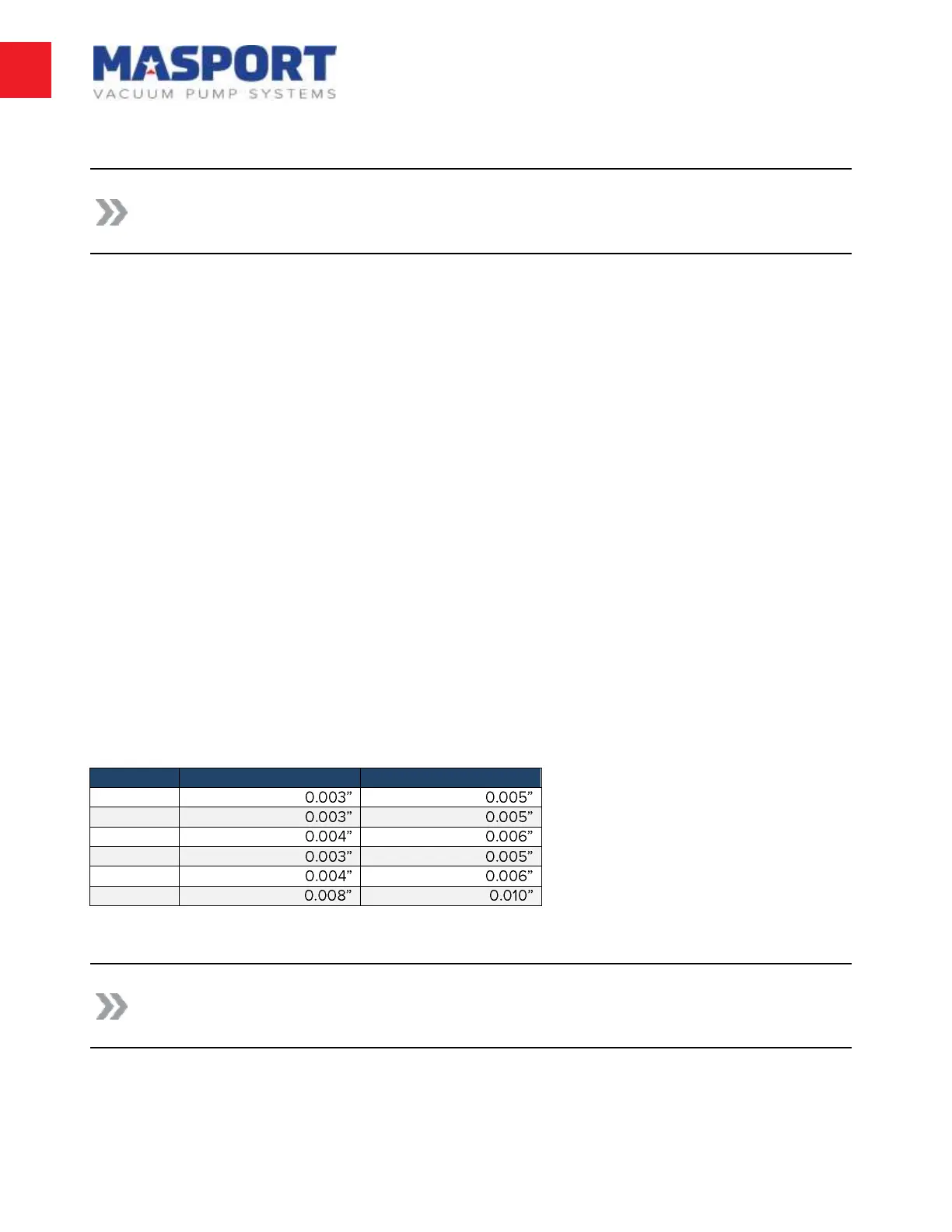

Checking and Setting the End Float Clearance:

The end float clearance is the distance of travel between the end faces of the rotor and the end

covers. The end clearance is set at a certain specification to provide the maximum performance and

efficiency.

The end float clearance for each of the pumps should meet the specifications detailed in the table

below:

To set/check the end float clearance the following procedure should be used:

Note: The following procedure will require the use of a dial indicator and either a

magnetic stand or a stand that can be bolted to one of the end cover bolts.

Loading...

Loading...