Maintenance and Adjustment

68

410/420/430 - 001 8903 U1

UZEL

Fuel filter

Change the fuel filter element every 500 hours.

1. Place a suitable container below the fuel filter

assembly to retain spilled fuel oil. Clean the outside

of the filter assembly.

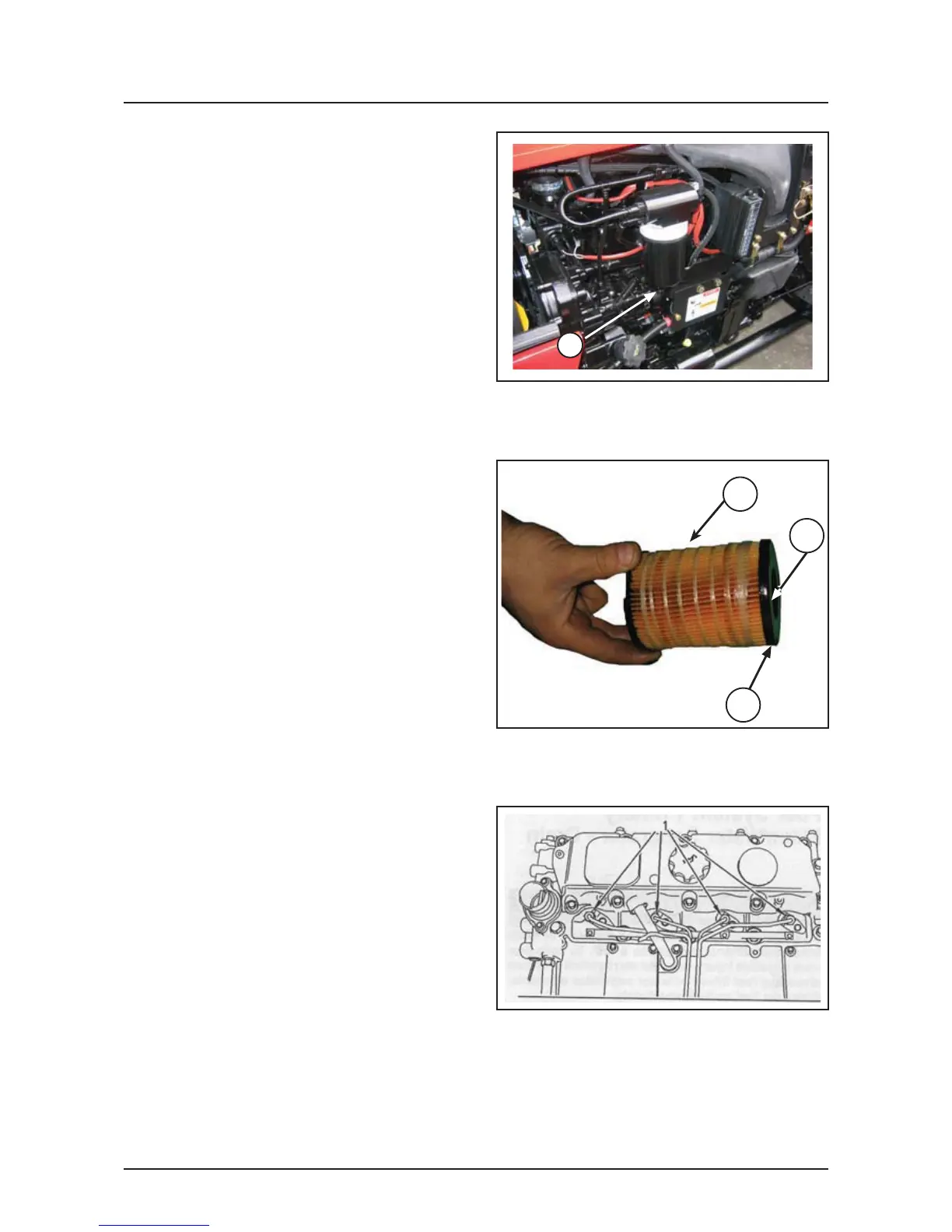

2. Open the drain tap (1, Fig. 88) at the bottom of

the filter casing to drain the fuel from the filter.

3. Use a strap wrench to loosen the filter casing.

Remove the casing and element from the fuel filter

head.

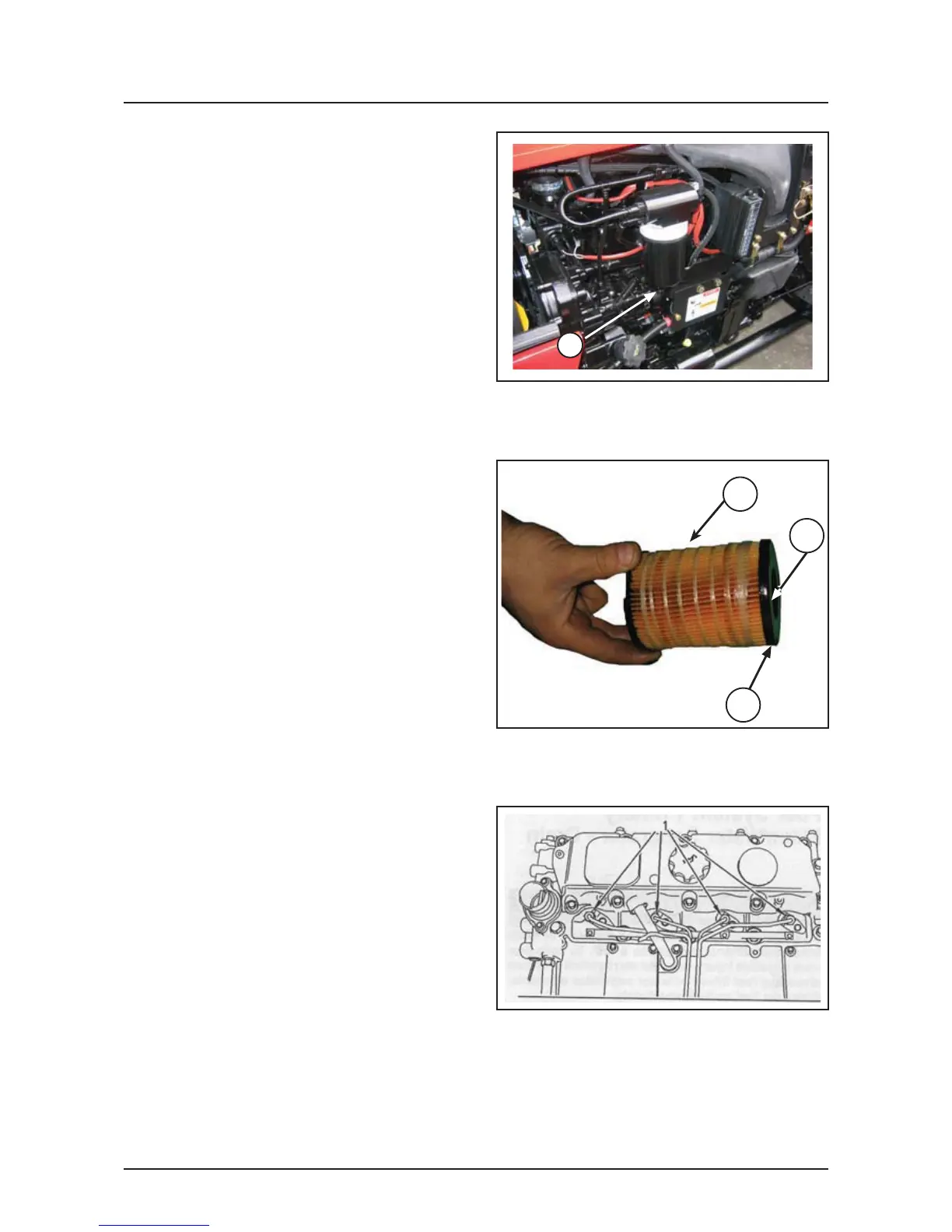

4. To remove the filter element from the casing; press

down on the filter element (1, Fig. 89) against the

spring pressure and rotate the element to the left to

release it from the filter casing .

5. Put the new filter element inside the casing and

press the element down against the spring pressure.

Rotate the element to the right to lock the element

into the casing

6. Fit a new seal (3, Fig. 89) to the casing and lightly

lubricate the seal face with clean fuel oil.

7. Check that the thread (2, Fig. 89) on the inside of

the element is not damaged.

8. Fit the filter assembly to the filter head and tighten

by hand until the filter assembly contacts the filter

head. Tighten the assembly a further 1/8 of a turn

by hand. Do not use a strap wrench.

9. Close the drain tap (1, Fig. 88) and remove the

container.

Removing air from the fuel system

If at any time air enters the fuel system, either due

to fuel system servicing, running out of fuel, tractor

standing idle for a considerable time or difficulty with

starting, the following procedure must be used to

remove air from the system:

NOTE: If air removal temporarily eliminates the

problem, but it occurs again, you must fully check

and test all fuel lines and connections. Loose fuel

connections and gasket surfaces, or damaged fuel

lines, can allow air to enter the system without showing

any apparent leakage.

1. Remove the cover for the fuel injectors (Fig. 90).

Refer to the Disassembly and assembly Manual.

2. Turn the key switch to the RUN position. Leave

the key switch in the RUN position for three minutes.

3. Turn the key switch to the OFF position.

NOTE: Damage to the fuel injection pump, to the

battery, and to the starter motor can occur if the

starter motor is used excessively to purge the air

from the fuel system.

4. Loosen the flare nuts ( 1 ) for the high pressure

fuel lines on all of the fuel injectors.

IMPORTANT: DO NOT crank the engine continuously

for more than 30 seconds. Allow the starting motor

to cool for two minutes before cranking the engine

again.

5. Observe the connection at the flare nut. Operate

the starting motor and crank the engine until the fuel

is free of air.

6. Tighten the flare nuts ( 1 ) to a torque of 30 Nm.

7. The engine is now ready to start. Operate the

engine at low idle for a minimum of five minutes

immediately after air has been removed from the

fuel system.

NOTE: Running the engine for this period of time will

help ensure that the pump is completely free of air.

Fig. 88

Fig. 89

Fig. 90

Valve tip clearances

The valve tip clearances should be checked by your

Massey Ferguson Dealer every 1500 hours.

1

2

1

3

Loading...

Loading...