7

Evaporator Coils

To minimize damage to the evaporator coil, it is recommended that the carton (or crate) not be removed

until the evaporator coil is moved close to its final location. When the container is removed from the

evaporator coil, extreme care must be used when lifting and mounting to the ceiling, to prevent sheet

metal damage. Consult evaporator “Operating and Installation

Instructions” for proper installation details.

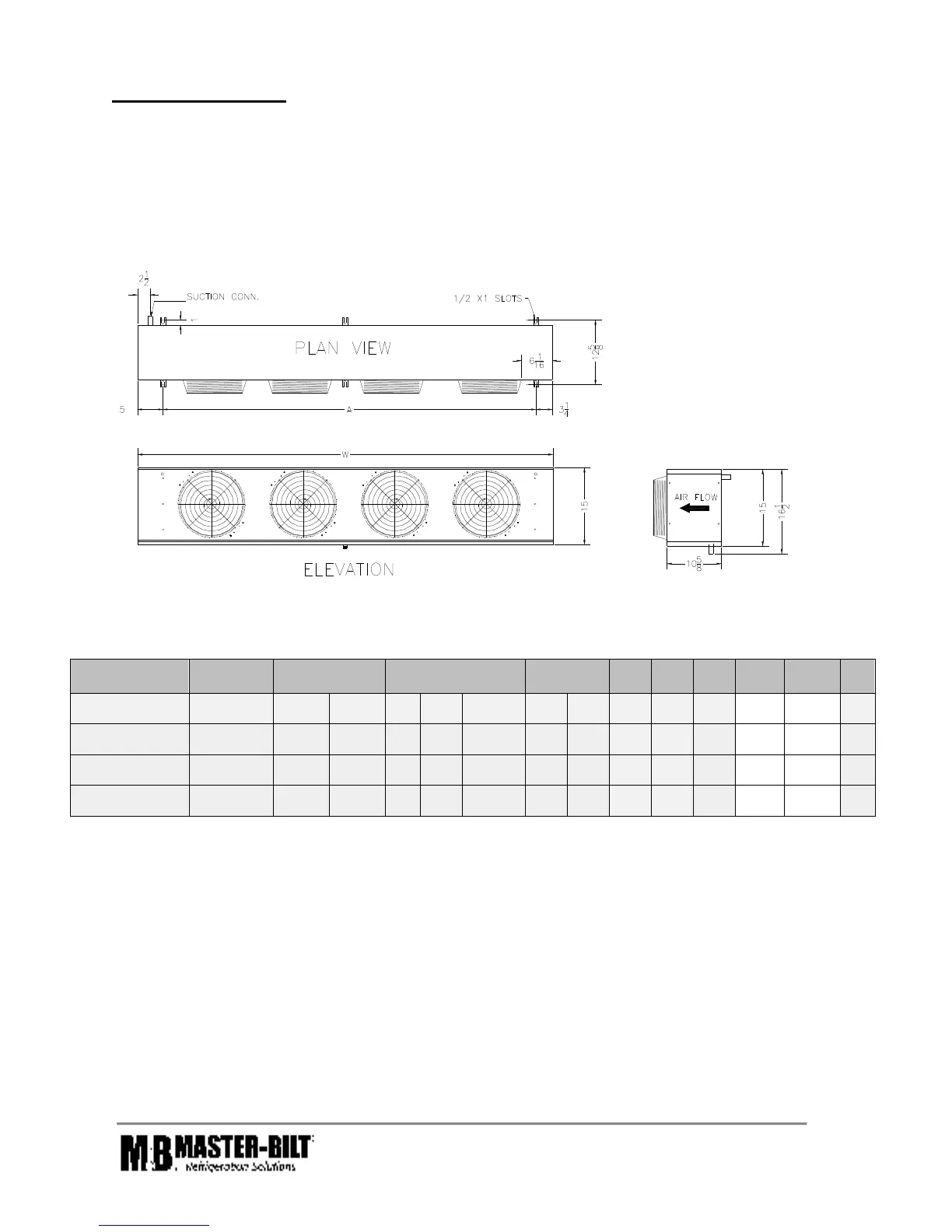

Dimensional Data

Table 2.

Specifications of evaporators

Model Description

Capacity

Refrig. BTUH*

Connection

Inlet Outlet Drain

Amps (230)

Mtrs Htrs

MCA

MOP

Wt.

lbs.

“A”

in

“W”

in

No.

Fan

EMMD0136B-MA

MAC-7,8

COOLER

R-449A

13600

3/8

OD

7/8

OD

3/4 MPT 1.0

15 20 58

33.25 43-5/8

2

EMLD0142B-MR

MAC-7

FREEZER

R-449A

14200

1/2

OD

1 1/8

OD

3/4 MPT 1.5 4.8 15 20 78

49.25 60-1/8

3

EMLD0187B-MR

MAC-8

FREEZER

R-449A

18700

5/8

OD

1 1/8

OD

3/4 MPT 2.0 6.4 15 20 124

65.25 76-5/8

4

EMLD0228B-MR

MAC-8C

FREEZER

R-449A

22800

5/8

OD

1 1/8

OD

3/4 MPT 2.5 8.1 15 20 195

81.25 93-1/8

5

* Based on 10

°

F TD, +25

o

F SST for med-temp, -20

o

F SST for low-temp

(MA/MR) - 208-230V / 1 phase /EC Motors, W/Master Controller, Electric Expansion Valve pre-mounted

The evaporator units are built in with Master Controller 3.2 system. It has standard demand defrost

features. The number of defrosts per day varies depending on moisture condition in the freezer. For more

information of a Master Controller 3.2 System, please consult the Master Controller 3.2 System I/O

Manuals.

Loading...

Loading...