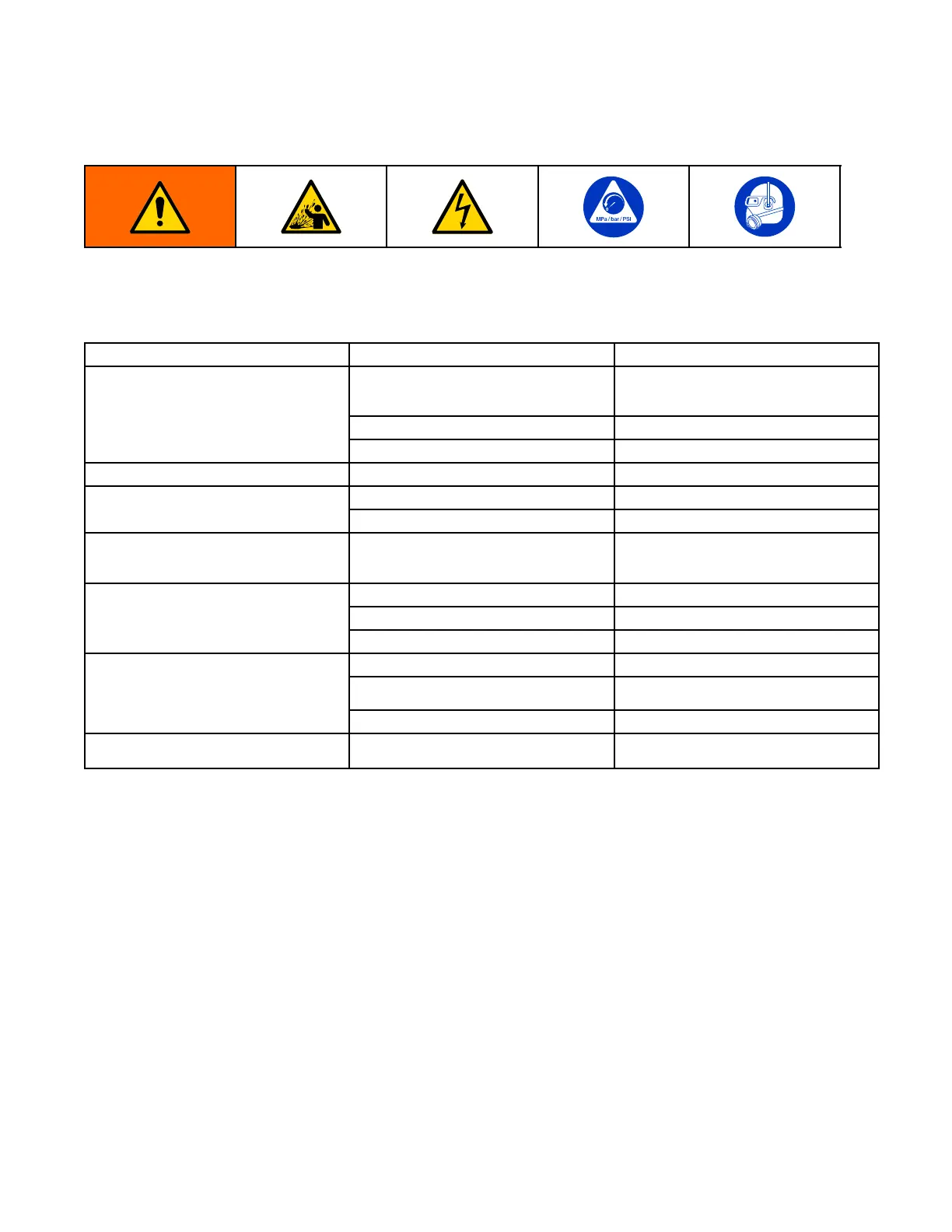

Troubleshooting

Troubleshooting Troubleshooting

Troubleshooting

•FollowthePressureReliefProcedure,page7,

beforecheckingorservicingtheequipment.

•Checkallpossibleproblemsandcausesbefore

disassembly.

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Pumpheadcentersectionhasno

CO

2

pressure,orCO

2

pressureistoo

low.

CheckCO

2

supply,adjustCO

2

to150

psi.

Checkvalvesarewornordamaged.

Replacethecheckvalves.

Pumpcyclesbutwillnotprimeand/or

pump.

Inletoroutlethoseisshutoff.

Removetherestriction.

Thecentersectionisexcessivelyhot.

Thedriveshaftisbroken.

Replace.

Motororcontrolleriswiredimproperly.Wirepermanual. Motorwillnotrun.

Nopowertomotor.

Checkelectricalcircuit.

Themotorisoperating,butthepump

willnotcycle.

Thejawcouplingbetweenthe

motorandgearboxisnotconnected

properly.

Checkthemotorcoupling.

Inletoroutlethoseispinched.Inspecthoses.

Checkvalvesarestickyorbent.Cleanorreplacecheckvalves.

Pumpowrateiserratic.

Diaphragmruptured.Replacediaphragms.

CO

2

ttingislooseorhosedamaged.InspectCO

2

ttingsandhoses.

Looseordamagedo-ringsorshaft

sealincentersection.

Rebuildcentersection.

CO

2

consumptionishigherthan

expected.

Diaphragmruptured.Replacediaphragms.

Pumpleaksexternallyfromjoints.

Loosediaphragmcoverscrewsor

ttings.

Checkscrewsandttingsfor

tightness.

63A7034A

Loading...

Loading...