8

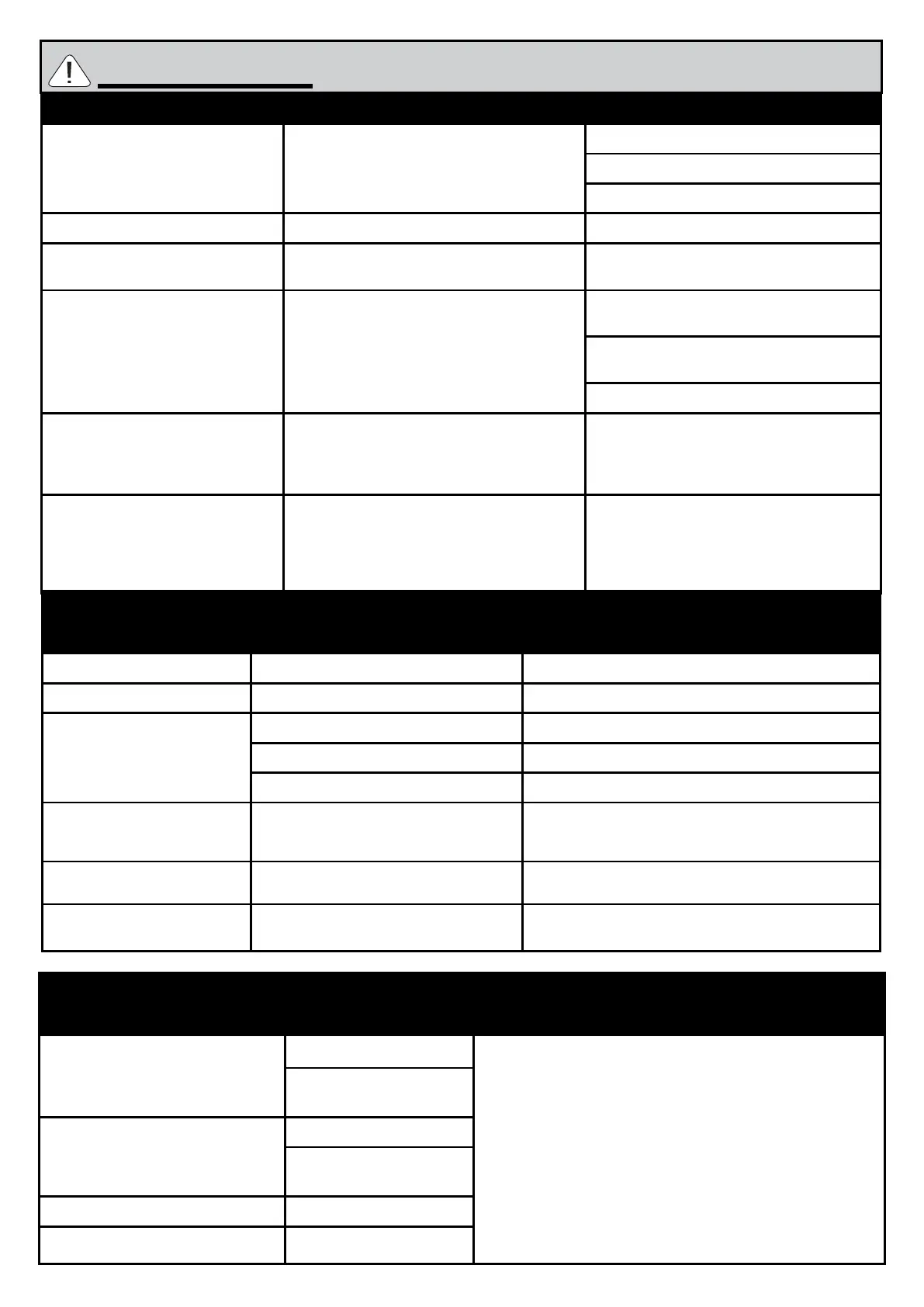

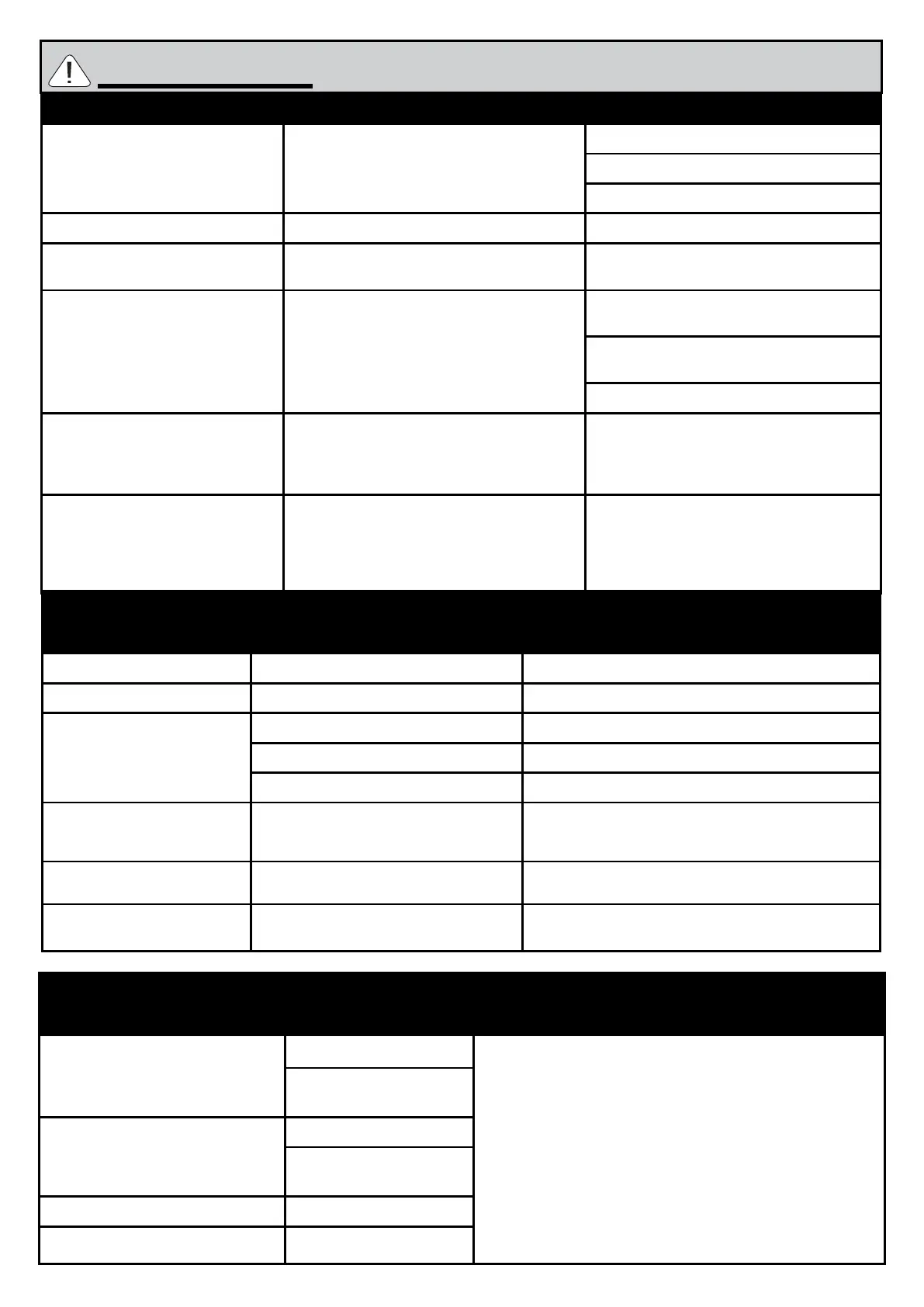

Emergency Cause Possible Solution

Gas leaking from cracked, cut or

burned hose

Damaged hose Turn o gas at LP cylinder.

Replace hose.

Contact Masterbuilt at 1.800.489.1581.

Gas leaking from LP cylinder Failure due to rust or mishandled equipment Replace LP cylinder.

Gas leaking from gas cylinder valve Failure of valve due to rust, mechanical

failure or mishandled equipment

Turn o gas cylinder valve and return

cylinder to gas provider/supplier.

Gas leaking between LP cylinder

and regulator connection

Improper installation, connection not tight

enough, damaged threads or bad rubber seal

Turn o gas cylinder valve, then re-attach

regulator to cylinder.

Turn o gas cylinder valve and return

cylinder to gas provider/supplier.

Visually inspect rubber seal for damage.

Fire under control panel Fire in tube of burner due to burner blockage

Turn o both burner control knob and gas

cylinder valve. Once the re is out and

burner has cooled, remove and inspect

burner for spiders, nests, rust or other debris.

Grease re or excessive/

continuous ame

Grease build up on or around burner area

Turn o both burner control knob and gas

cylinder valve. Allow ames to extinguish

and time for unit to cool down. Clean grease/

food particles from/around burner or burner

area and surrounding surfaces.

WARNING

In the event of a gas leak that cannot be stopped, or if a

re occurs due to a gas leak, contact the re department.

TROUBLESHOOTING SOLUTIONS: “CAUSES” LOW OR NO FLOW/VAPOR LOCK/EXCESS FLOW

Symptom Cause Possible Solution

Burner doesn’t light after pressing

ignitor button

Low/no gas ow 1. Turn burner control knob to “O” position.

2. Turn gas cylinder valve knob to OFF.

3. Disconnect regulator from cylinder to relieve vapor

lock.

4. Reconnect regulator to cylinder by hand turning until

tight.

5. Slightly open the gas cylinder valve slowly and then

open further by turning 1 full turn.

6. You are now ready to light the smoker.

7. Turn the burner control knob to high and light with

ignitor.

Vapor lock at coupling nut

to LP cylinder

Low ame output Excess ow valve tripped

Vapor lock at coupling nut/

LP cylinder connection

Flames blow out Excess ow valve tripped

Slower than expected cooking times Vapor lock

TROUBLESHOOTING GUIDE

Symptom Cause Possible Solution

Low ame output* Out of fuel Rell or replace with full LP cylinder.

Flames blow out* Low on LP gas Rell LP cylinder.

Flare-up Excessive grease buildup Clean burner and inside unit.

Excessive fat on meat Trim fat o of meat.

Cooking temperature too high Adjust or lower temperature accordingly.

Persistent grease re Grease trapped by food buildup around

burner system

Turn burner control knob and gas cylinder valve o.

Allow re to extinguish and the unit to cool down.

Once cool, remove and clean parts.

Flashback (re in burner tube) Burner and/or burner tube has blockage Turn burner control knob and gas cylinder valve o.

Clean burner and/or burner tube.

Slower than expected cooking

times*

Valve not properly aligned to burner Check to see if valve is centered in burner tube.

* Also see Troubleshooting solutions: “Causes” Low or No Flow/Vapor lock/Excess ow below.

Loading...

Loading...