The following directions will give the beginner a start on jointer operations. Use scrap pieces of

lumber to check the settings and to get the feel of the operations before attempting regular work.

NOTE: The cutterheads on the jointer will not wear evenly by feeding the wood through the

same spot on the table every time. Feed the wood through the jointer at different spots on the table

to help eliminate uneven wear of the cutterheads.

WARNING: Always use cutterhead guard and keep hands away from cutterhead. Use push

blocks and push stick whenever possible.

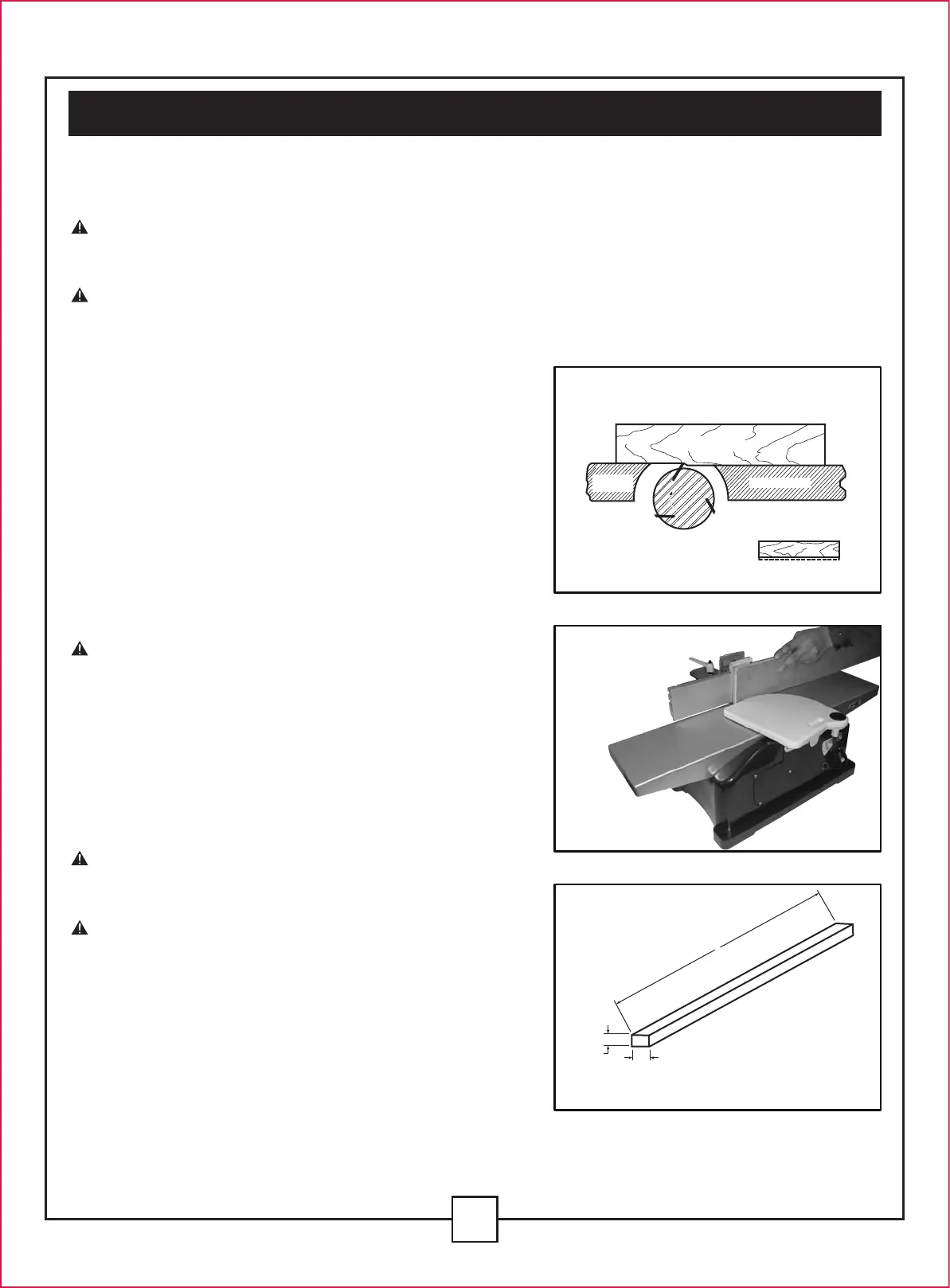

PLACEMENT OF HANDS DURING FEEDING

(Fig. 31)

At the start of the cut, the left hand holds the work firmly

against the infeed table and fence, while the right hand

pushes the work towards the cutterheads. After the cut

is underway, the new surface rests firmly on the outfeed

table as shown in Fig. 31. The left hand should then

be moved to the work on the outfeed table, at the same

time maintaining flat contact with the fence. The right

hand presses the work forward, and before the right

hand reaches the cutterhead it should be moved to

the work on the outfeed table.

WARNING: Never pass hands directly over the

cutterhead.

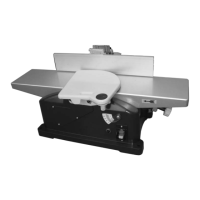

JOINTING AN EDGE (Fig. 32-33)

This is the most common operation for the jointer. Set

the guide fence square with table. Depth of cut should

be the minimum required to obtain a straight edge. Hold

the best face of the piece firmly against the fence

throughout the feed as shown in Fig. 32.

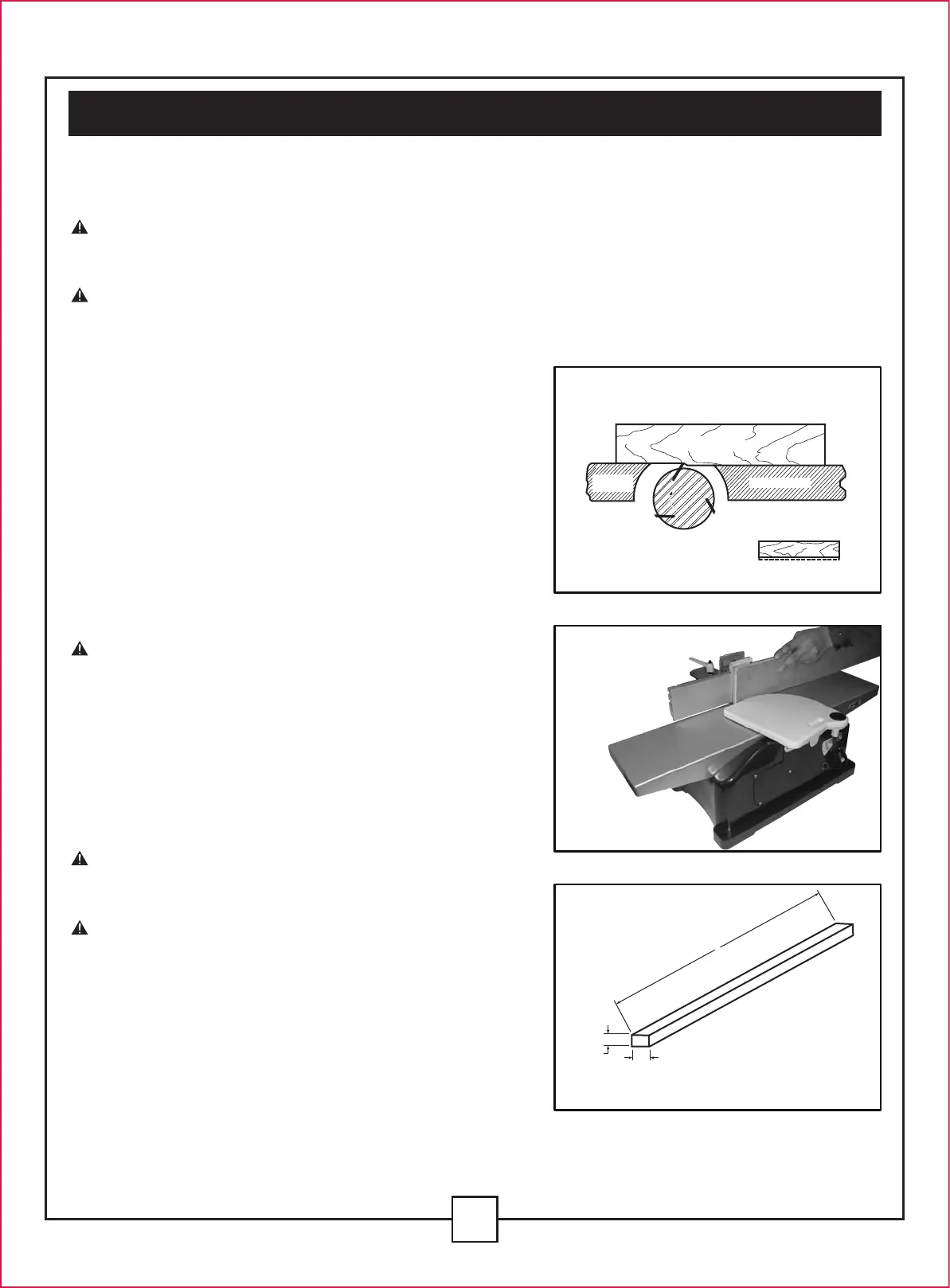

WARNING: Do not perform jointing operations on

material shorter than 10" (25.4 cm), narrower than 3/4"

(19 mm) or less than 1/4" (6 mm) thick (refer to Fig. 33)

NOTE: Always use hold-down/push blocks for

jointing material narrower than 3" (75 mm).

18

VI. Operating instructions (continued)

Fig. 31

Fig. 32

Fig. 33

MINIMUM JOINTING DIMENSIONS

OUT-FEED

TABLE

IN-FEED TABLE

10” MINIMUM

3/4” MINIMUM

1/4”

MINIMUM

CUTTERHEAD

MATERIAL

Loading...

Loading...