THANK YOU FOR USING OUR PRODUCTS

§5.2 Troubleshooting

All welding machines have undergone 100% inspection before leaving the factory.

Disconnect power cord from LINE before any trouble shooting and only professional

maintenance personal should perform any action on the machine!

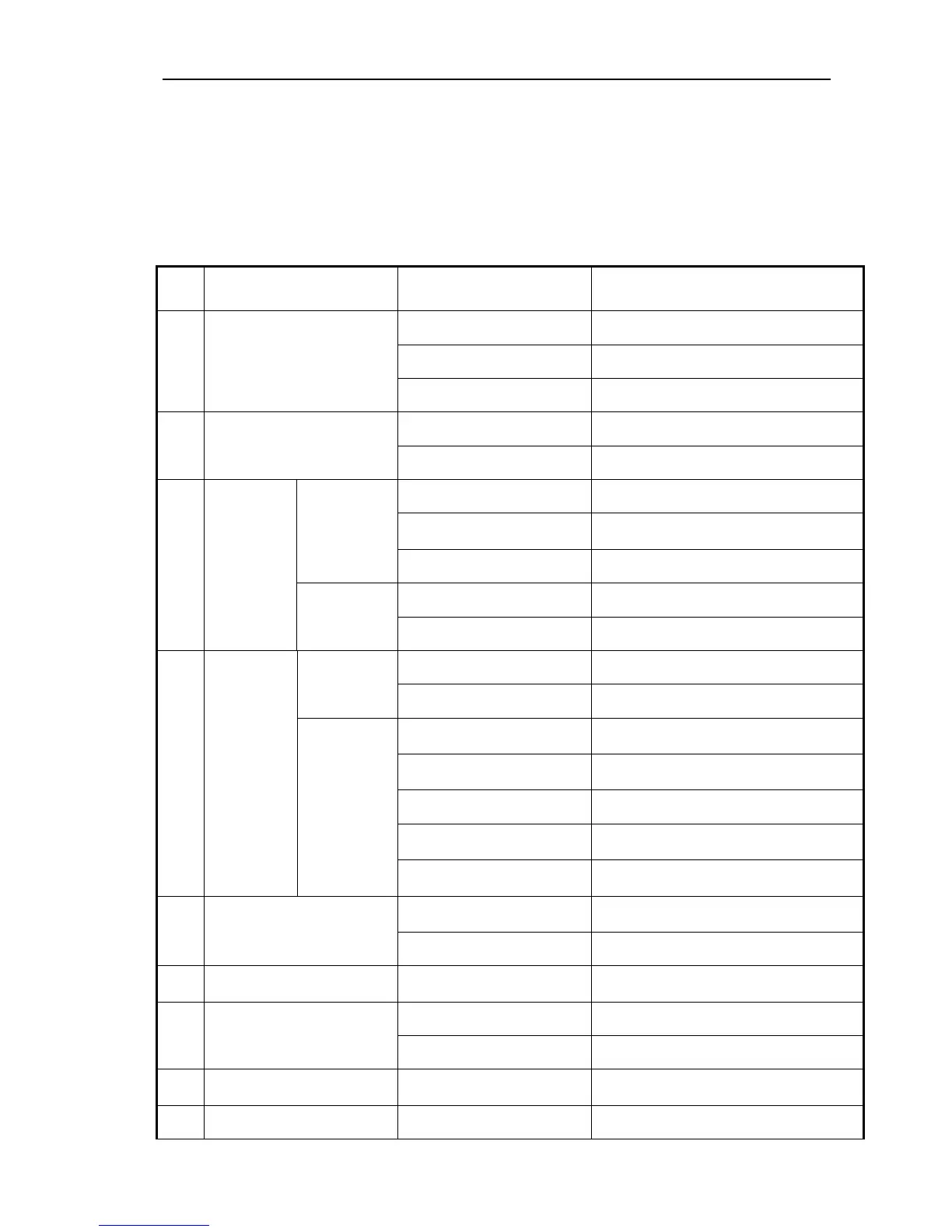

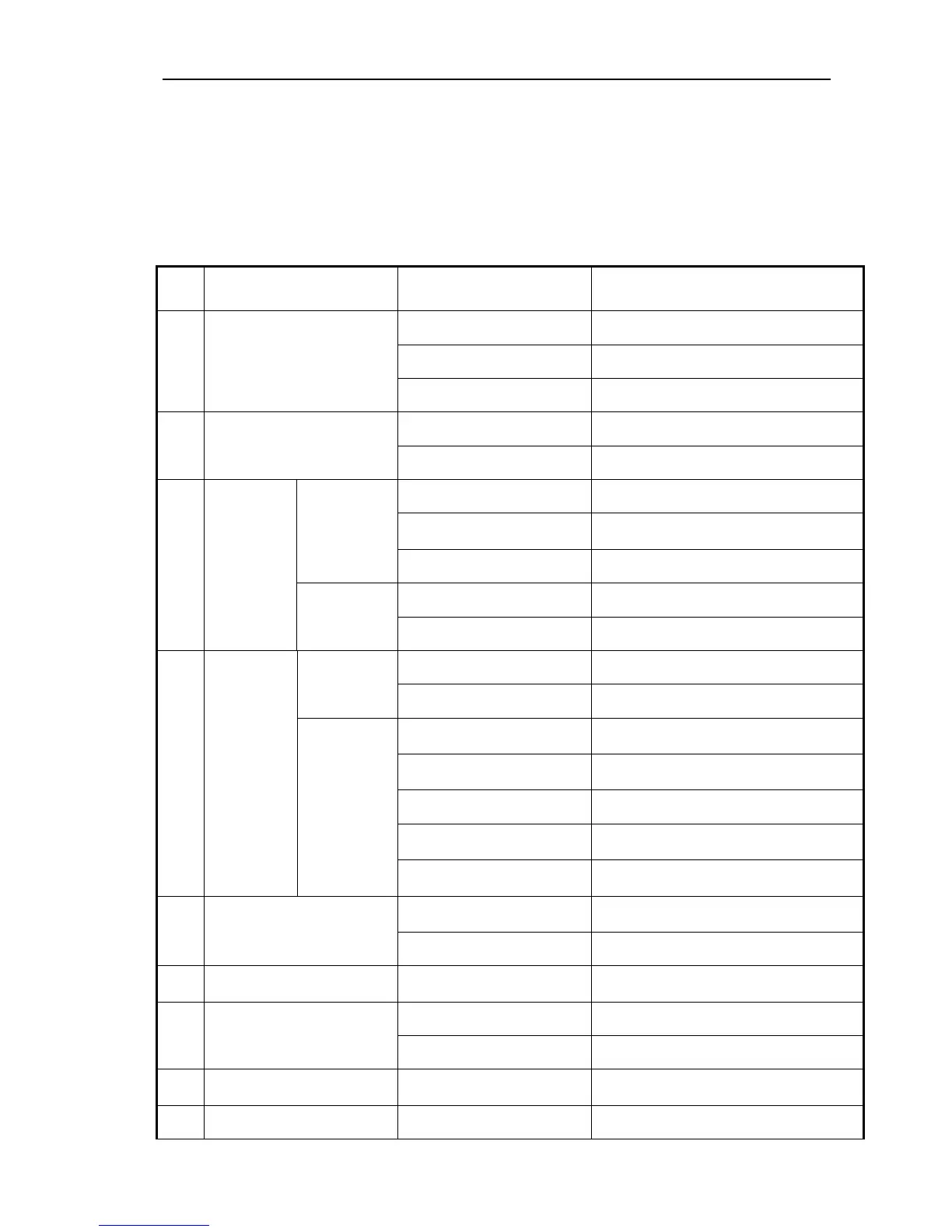

Item Trouble Reasons Solution

1

Power switch “ON” but the

power light not illuminated

Breaker open or damaged Check circuit breaker

Power switch damaged Replace switch

Power cord damaged Replace cord

2

Machine over-

functioning

Fan damaged Clear obstruction or replace

The cable is loosen Secure the cable tightly

3

Depress

trigger

switch, no

output

shielded gas

No output

gas when test

gas

No gas in cylinder or closed Open valve or fill cylinder

Low gas flow or leaks in

hose and fittings

Adjust regulator flow, secure fittings

Gas solenoid valve problem Check and replace if required

Output gas

when test gas

Control switch damaged Repair the switch

Control circuit damaged Check the board

4

Depress

trigger

switch, no

wire feed

Wire feeder

doesn’t turn

Motor damaged Check and replace

Control circuit damaged Check and replace wire feed board

Wire feed

turns but no

wire feed at

nozzle

Welding wire skids over

drive roller wheel

Check tension arm & tighten

Welding wire skids over

drive roller wheel

Confirm roller groove matches wire dia.

Drive roller worn Replace

Wire won’t feed through

gun with tip removed

Replace torch wire conduit liner

Wire won’t feed through

gun with tip installed

Wrong size or worn contact tip, change

5

Output cable is connected

incorrectly or loose terminal

Screw it down or change it

Control circuit damaged Check the circuit

6

Welding stops and over-

temp light illuminates

Machine has reached duty-

cycle limit or internal dust

Stop welding for 10-minutes to allow

cool down. Auto-reset will turn lamp off

7

Welding current is run away

and can be not controlled

The potentiometer damaged Check or change it

The control circuit damaged Check the circuit

8

The crater current can be not

adjusted

The PCB damaged Check it

9 Weld is inconsistent Inadequate or wrong gas Change cylinder to correct

Loading...

Loading...