TI008G0001

7.03

Maintenance

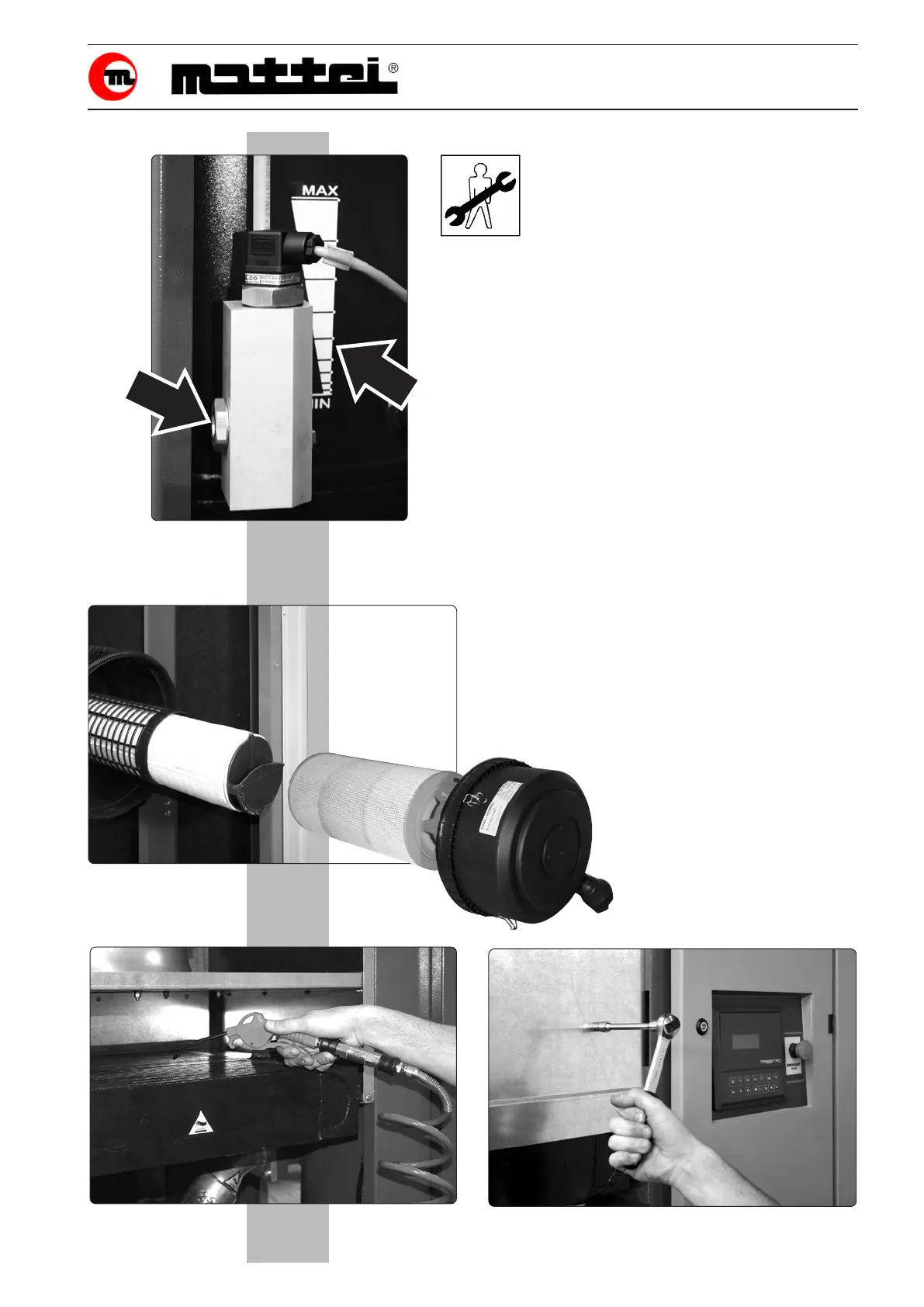

Check of oil level (Photo 1)

With compressor not operating and with-

out pressure inside the chamber the oil

level should be included between the MIN

and MAX levels shown on the specic in-

dicating sticker (g. 1).

When the compressor is running and on load, the

oil level should be over the visual indicator half

(g. 1).

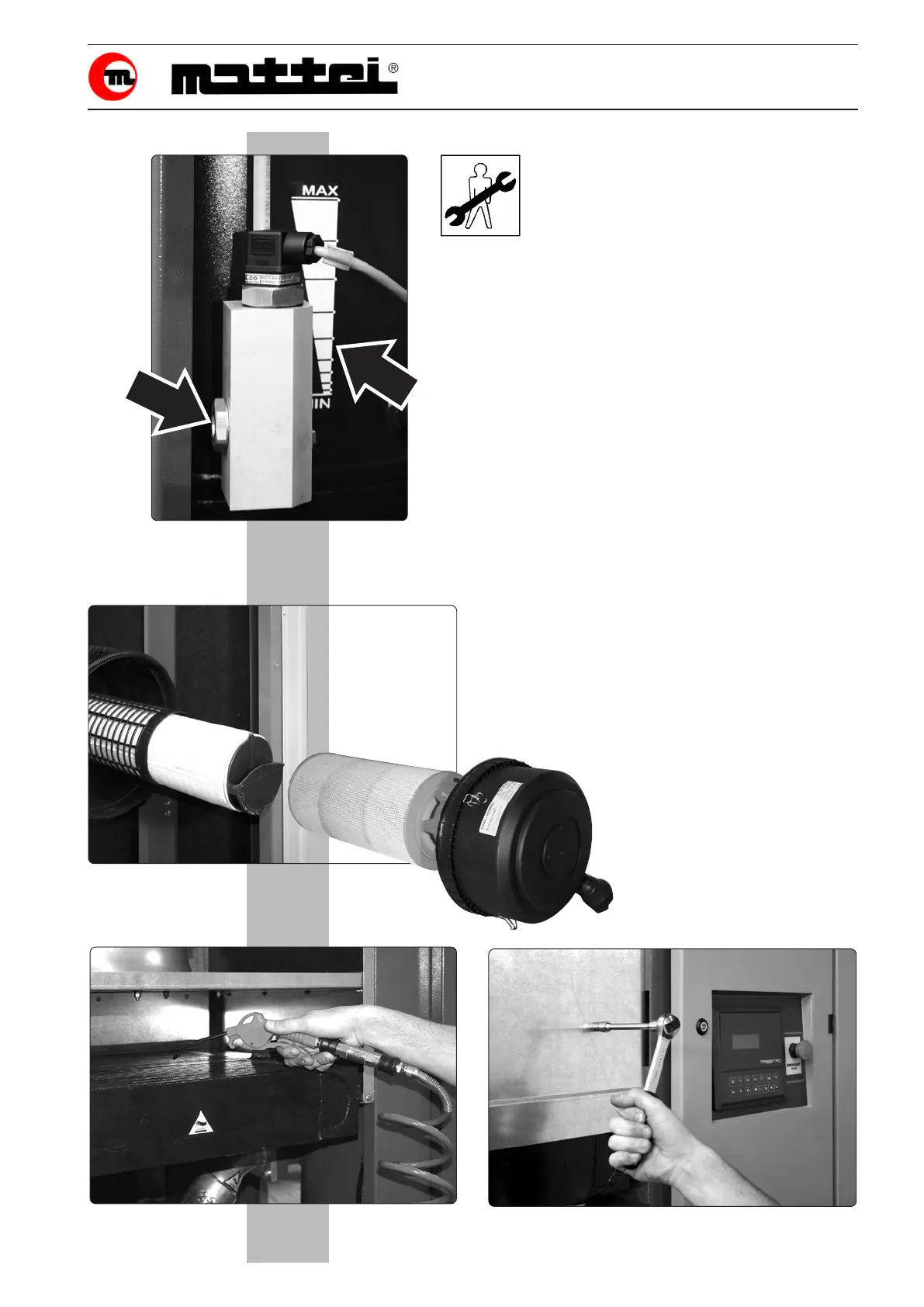

Cleaning/replacing the air intake lter

(Photo 2)

Release the xing hooks to remove the lter cover.

Firstly take out the outer element, then the inner

element by using the specic knob. Clean with

compressed air, directing the air jet from the inside

to the outside. Reassemble in the reverse order.

To clean the air end, remove

the soundproof panel and

proceed as above, by blow-

ing the radiator by means of

a compressed air ow.

Therefore the dust deposits mainly on the bottom.

To clean the oil radiator, remove the fan guard panel

(photo 4) and blow the radiator with a compressed

air ow.

Cleaning the oil/air radiator (Photo 3)

Considering the air ow used to wash the compres-

sor, the radiator is crossed by an air ow directed

from downwards to upwards.

924

4

223

3

222

2

618

101

1

Loading...

Loading...