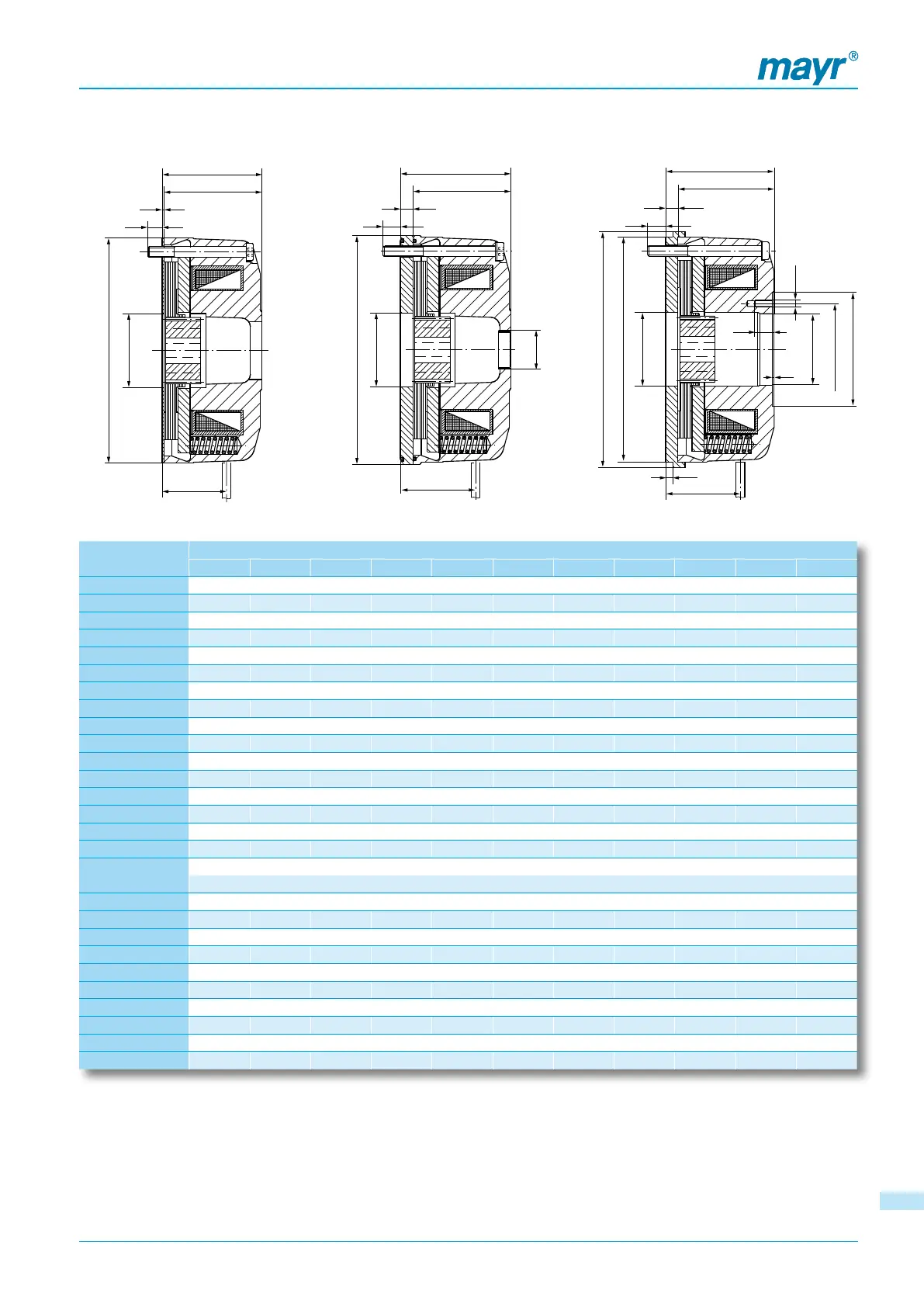

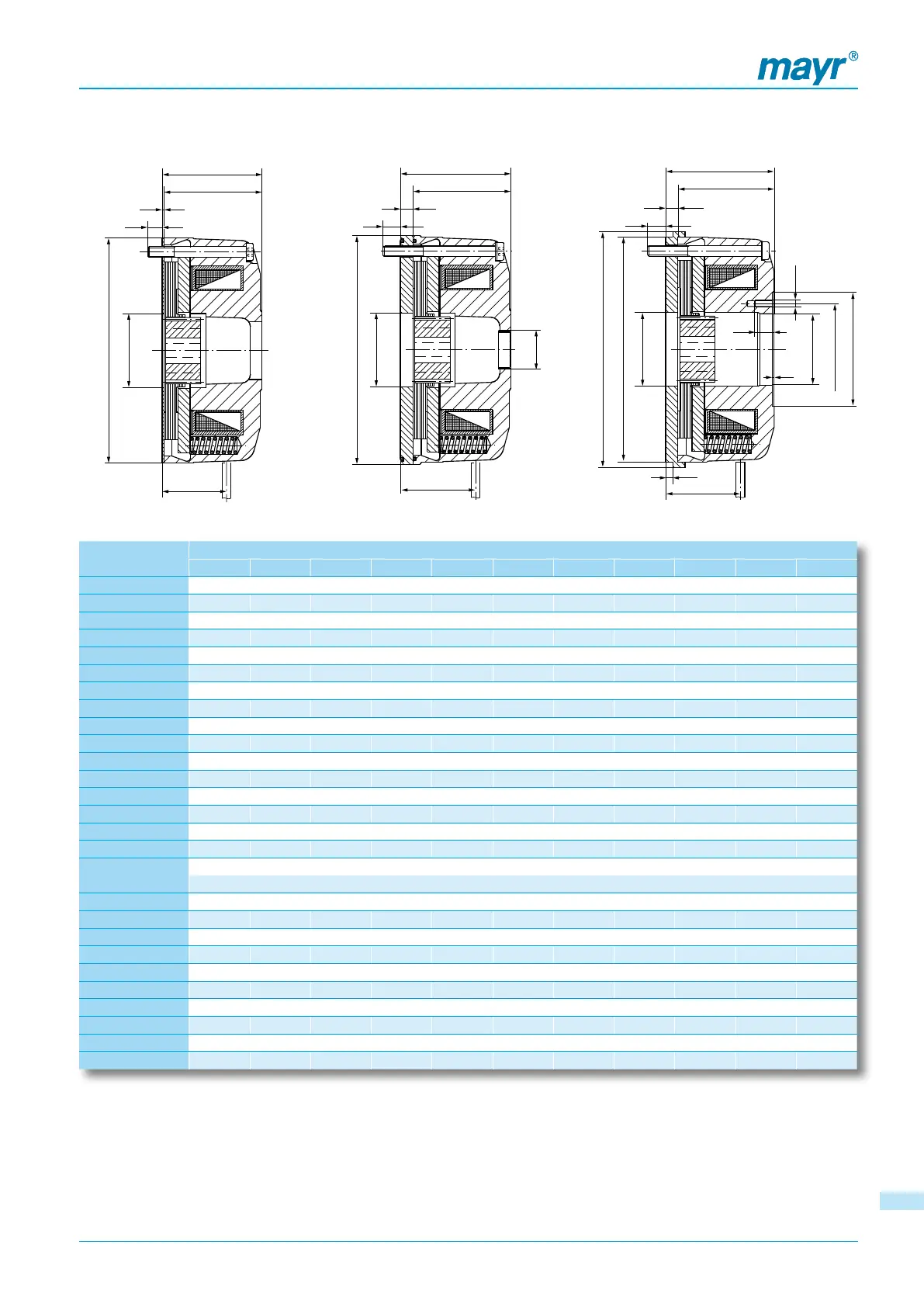

L

4

L

h

1

K

2

Ø b

Ø D

1 h9

*

c

2

Ø G

2

H8

g

c

2

Ø b

Ø Z

Ø s

1

z

t

Ø D

g7

Ø G

1

H7

Ø D

2

Ø M

1

L

5

L

2

h

1

K

3

ROBA-stop

®

-M electromagnetic safety brakes

Type 891._12.0

Standard with friction disk

Type 891._14.1

Enclosed design (IP 65)

with flange plate

Type 891._14.2

Tacho attachment design

with flange plate

1) Braking torque tolerance = +30 %/-10 %, for other adjustments see

Table 3, page 7 and Type key page 3.

1.1) Minimum bore not permitted for braking torque adjustment = 125 %.

1.2) Braking torque tolerance = +40 %/-20 % (slight grinding necessary).

2) The respective maximum bores are to be seen in relation to the

corresponding keyways and their tolerances acc. Table 2 page 7.

3) Brake operation from 700 Nm on only possible with overexcitation.

4) Hub facing side (both sides) 3 mm deep, Ø 97 recessed.

5) Brake operation only possible with overexcitation.

6) The IP65 design is equipped with a sealing cover on size 1000:

L = 149 mm, L

4

= 170 mm.

7) Projection screw plugs (emergency hand release): 8,5 mm

8) For flange plate securement: additional 2 x M12 screws (dimensions

available on request).

Standard voltages 24; 104; 180; 207 V. We reserve the right to make dimensional and constructional alterations.

Permitted voltage tolerance acc. DIN IEC 60038 (±10 %).

* Outer diameter friction disk: free size; outer diameter flange plate: -0,2 Missing dimensions are identical with Type 891.011.0 see page 4.

Dimensions

[mm]

Size

2 4 8 16 32 60 100 150 250 500 1000

G 16,5 18 22 33 36 38 48 55 65 85 100

G

1

23,5 28,5 32,5 40,5 52,5 60 75,5 82,5 92 131 100

G

2

H8

- - 22 22 28 32 42 48 52 62 100

g 4 4 4 4 4 4 5 6 7 7 7

H 16 14,5 17,5 26 27 26 34 41 46 54,5 -

h 1 1 1 1,25 1,25 1,25 - - - - -

h

1

5 6 6 7 8 8 10 12 14 19 21

K 10 10,8 12,5 12,3 8,3 12 12 20 20 22 18,5

K

1

9 9,8 11,5 11,1 7,1 10,8 - - - - -

K

2

10 8,8 11,5 10,3 10,3 14 12 18 25,5 21,5 17,5

K

3

10 9,8 11,5 10,3 10,3 14 12 18 26 23 19

L 39 41,5 45,2 55,7 61,7 72,5 84 97 116 114 135

6) 7)

L

2

38 40,5 44,2 54,7 60,7 71,5 83 96 115 113 135

7)

L

3

40 42,5 46,2 57 63 73,8 - - - - -

L

4

44 47,5 51,2 62,7 69,7 80,5 94 109 130 133 170

6)

L

5

43 46,5 50,2 61,7 68,7 79,5 93 108 129 132 156

7)

l

18 18 20 20 25 30 30 35 40 50

4)

70

supporting length of the key

M 66 72 90 112 132 145 170 196 230 278 325

M

1

29 35 41 52 61 75 88 100 112 145 115,5

R 57 65 81 101 121 130,5 154 178 206 253 300

r 45 45 53 70 83 94 106 122 140 161 190

s 3 x M4 3 x M4 3 x M5 3 x M6 3 x M6 3 x M8 3 x M8 3 x M8 3 x M10 6 x M10 6 x M12

8)

s

1

3 x M3 3 x M4 3 x M4 3 x M4 3 x M5 3 x M5 3 x M5 3 x M6 3 x M6 6 x M8 6 x M6

t 6 10 10 10 10 10 10 10 10 13 12

x 0 0 0 0 - 0,5 0 - 0,5 0 - 2 0 - 3 0 - 3 0 - 3 3 - 4 0 – 1,5

Z 36 45 55 65 75 90 100 115 130 175 -

z 1 1 1 1 1 1 1 1 1 1 -

55

Loading...

Loading...