ROBA-stop

®

-M – Brake Dimensioning

Brake Dimensioning

Friction work

per 0,1 mm

wear

Standard brake

Type 891.

0

_ _._

2

Q

r 0,1

[10

6

J/0,1] 35 40 65 100 130 130 140 150 160 200

Holding brake

Type 891.1_ _._

Q

r 0,1

[10

6

J/0,1] 7 8 13 20 30 65 70 75 80 100

Friction work

on rotor

replacement

Standard brake

Type 891.

0

_ _._

2

Q

r tot.

[10

6

J] 95 100 162 500 600 700 840 950 1000 2000

Holding brake

Type 891.1_ _._

Q

r tot.

[10

6

J] 7 8 13 20 45 130 170 300 350 500

Mass

moment

of inertia

rotor + hub

on d

max

Type 891.

0

_ _._

1

(Metal rotor)

J

[10

-4

kgm²] 0,12 0,21 0,67 1,74 4,48 6,74 16,54 31,68 61,82 222,6

Type 891.2_ _._

(Friction lining rotor)

J

[10

-4

kgm²] 0,1 0,17 0,58 1,53 4,1 - - - - -

Weight

Standard brake

Type 891.

0

_ _._

2

m

[kg] 0,76 1,1 1,8 3,4 4,5 7,4 13,6 19,2 33,3 38

Holding brake

Type 891.1_ _._

m

[kg] 0,76 1,1 1,8 3,4 4,5 7,4 13,6 19,2 33,3 38

Please Observe!

Due to operating parameters such as slipping speed, pressing or temperature, the wear values can only be considered guideline values.

When using a brake with a friction disk (Type 891._ _2._), the max. friction work and friction power must be reduced by 30 % for sizes 2 to

16 and by 50 % for sizes 32 – 60.

The wear values Q

r 0,1

and Q

r tot.

are therefore not valid.

1. Brake selection Key:

M

req.

=

9550 x P

x K ≤ M

2

[Nm]

J [kgm²]

Mass moment of inertia

n

K [-] Safety factor

(1 – 3 x acc. to conditions)

t

v

=

J x n

[sec]

9,55 x M

v

M

req.

[Nm]

Required braking torque

t

4

= t

v

+ t

1

[sec]

M

v

[Nm]

Delaying torque

M

v

= M

2

+ (-)* M

L

[Nm]

M

L

[Nm] Load torque * sign in brackets is valid if load

is braked during downward movement

2.

Inspection of thermic load

M

2

[Nm]

Nominal torque (Technical Data page 4)

Q

r

=

J x n²

x

M

2

[J/braking]

n [rpm]

Speed

182,4 M

v

P [kW]

Input power

t

v

[s]

Braking action

The permitted friction work (switching work) Q

r perm.

per braking for

the specified switching frequency can be taken from the friction-

power diagrams (page 9).

If the friction work (switching work) per braking is known, the max.

switching frequency can also be taken from the friction-power

diagrams (page 9).

t

1

[s]

Connection time (Table 6 page 10)

t

4

[s]

Total switch-on time

Q

r

[J/braking] Friction work present per braking

Q

r 0,1

[J/0,1] Friction work per 0,1 wear (Table 4)

Q

r tot.

[J] Friction work up to rotor replacement (Table 4)

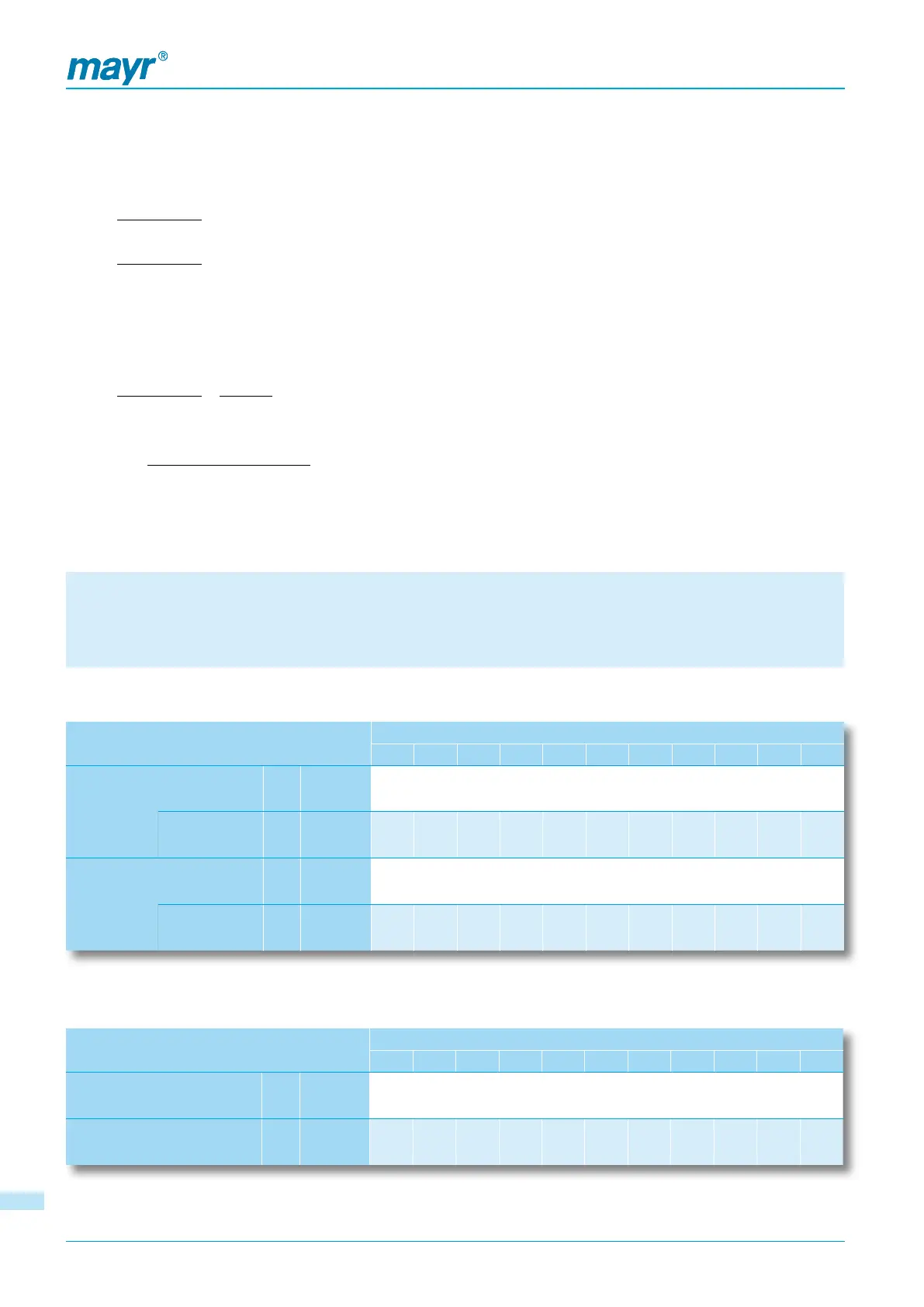

Brake Size Selection

Mass Moment of Inertia

Size

Rotor + hub at d

max

2 4 8 16 32 60 100 150 250 500 1000

Type 891.

0

1

_ _._

(Metal rotor)

J

R+H

[10

-4

kgm²] 0,12 0,21 0,67 1,74 4,48 6,74 16,54 31,68 61,82 222,6 424

Type 891.2_ _._

(Friction lining rotor)

J

R+H

[10

-4

kgm²] 0,1 0,17 0,58 1,53 4,1 - - - - - -

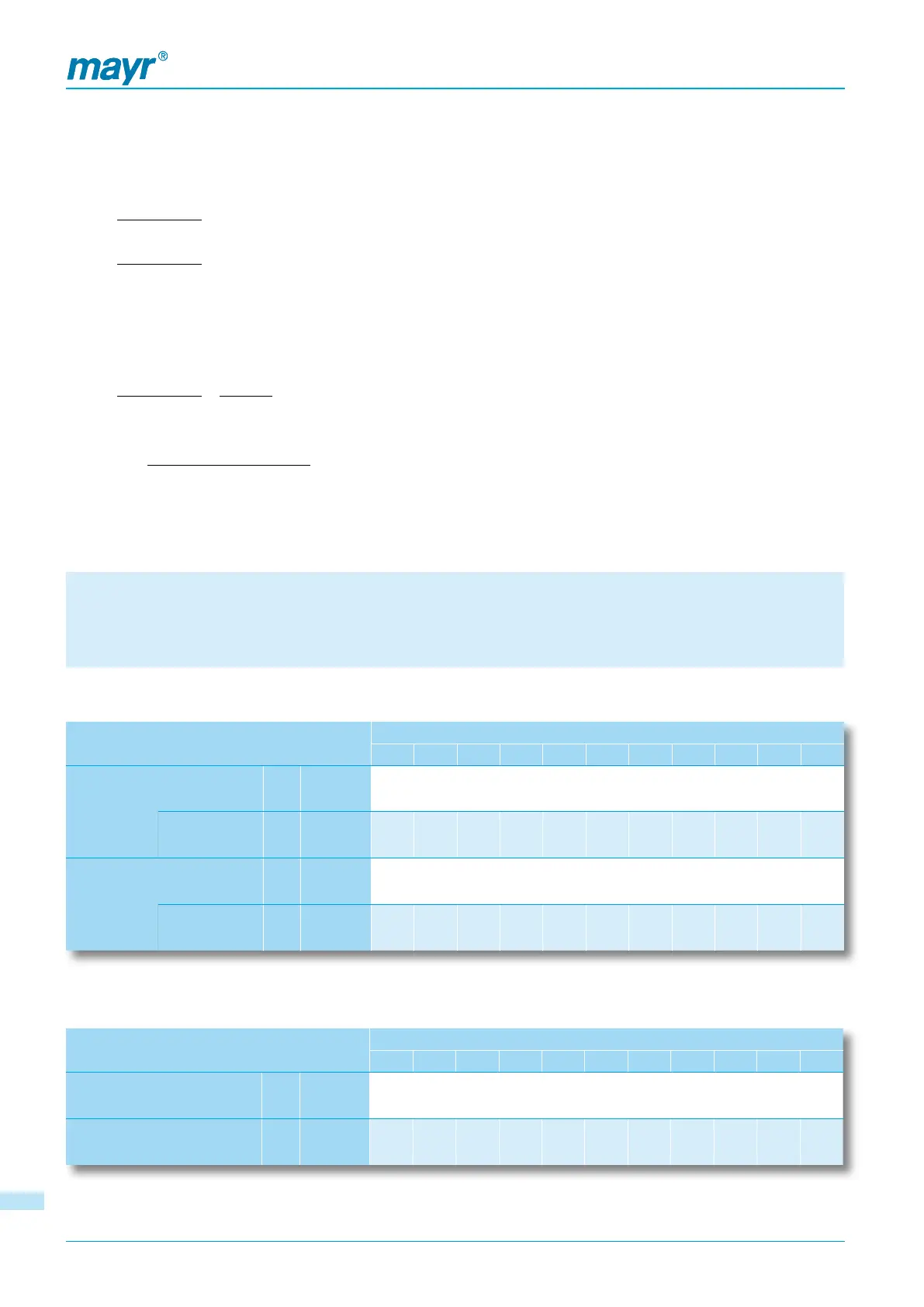

Table 5

Friction Work

Size

2 4 8 16 32 60 100 150 250 500 1000

Per 0,1 mm

wear

Standard brake

Type 891.

0

2

_ _._

Q

r 0,1

[10

6

J/0,1] 35 40 65 100 130 130 140 150 160 170 180

Holding brake

Type 891.1_ _._

Q

r 0,1

[10

6

J/0,1] 7 8 13 20 30 65 70 75 80 85 90

Up to rotor

replacement

Standard brake

Type 891.

0

2

_ _._

Q

r tot.

[10

6

J] 95 100 162 500 600 700 840 950 1000 1700 2000

Holding brake

Type 891.1_ _._

Q

r tot.

[10

6

J] 7 8 13 20 45 130 170 300 350 425 540

Table 4

88

Loading...

Loading...