IOMM ACZ1 ACZ 010A through 039A

7

3.

Manual or automatic air vent valves at the high points of the system. Install drains at the lowest

points in the system.

4.

A means of maintaining adequate system water pressure (expansion tank or regulating valve).

5.

Temperature and pressure indicators located at the unit to aid in unit servicing. Pressure gauge

taps must be installed in the chilled water inlet and outlet piping or as shown in Figure 4.

6.

A strainer or other means of removing foreign matter from the water before it enters the pump.

Place the strainer far enough upstream to prevent cavitation at the pump inlet (consult pump

manufacturer for recommendations). The use of a strainer will help prolong pump life and keep

system performance up.

7.

A 40-mesh strainer is required in the water line just before the inlet of the evaporator. This will

help prevent foreign material from entering and decreasing the performance of the evaporator.

8.

If the unit is used as a replacement chiller on a previously existing piping system, flush the

system thoroughly before unit installation. Regular water analysis and chemical water treatment

on the evaporator is recommended immediately at equipment start-up.

9.

When glycol is added to the water system for freeze protection, the refrigerant suction pressure

will be lower, cooling performance less, and water side pressure drop greater. If the percentage

of glycol is high, or if propylene is used instead of ethylene glycol, the added pressure drop and

loss of performance could be substantial. Reset the freezestat and low leaving water alarm

temperatures. The freezestat is factory set to default at 38°F (3.3°C). Reset the freezestat setting

to approximately 4 to 5 degrees F (2.3 to 2.8 degrees C) below the leaving chilled water setpoint

temperature.

10.

Perform a preliminary leak check before insulating the piping and filling the system.

11.

Piping insulation should include a vapor barrier to prevent condensation and possible damage to

the building structure.

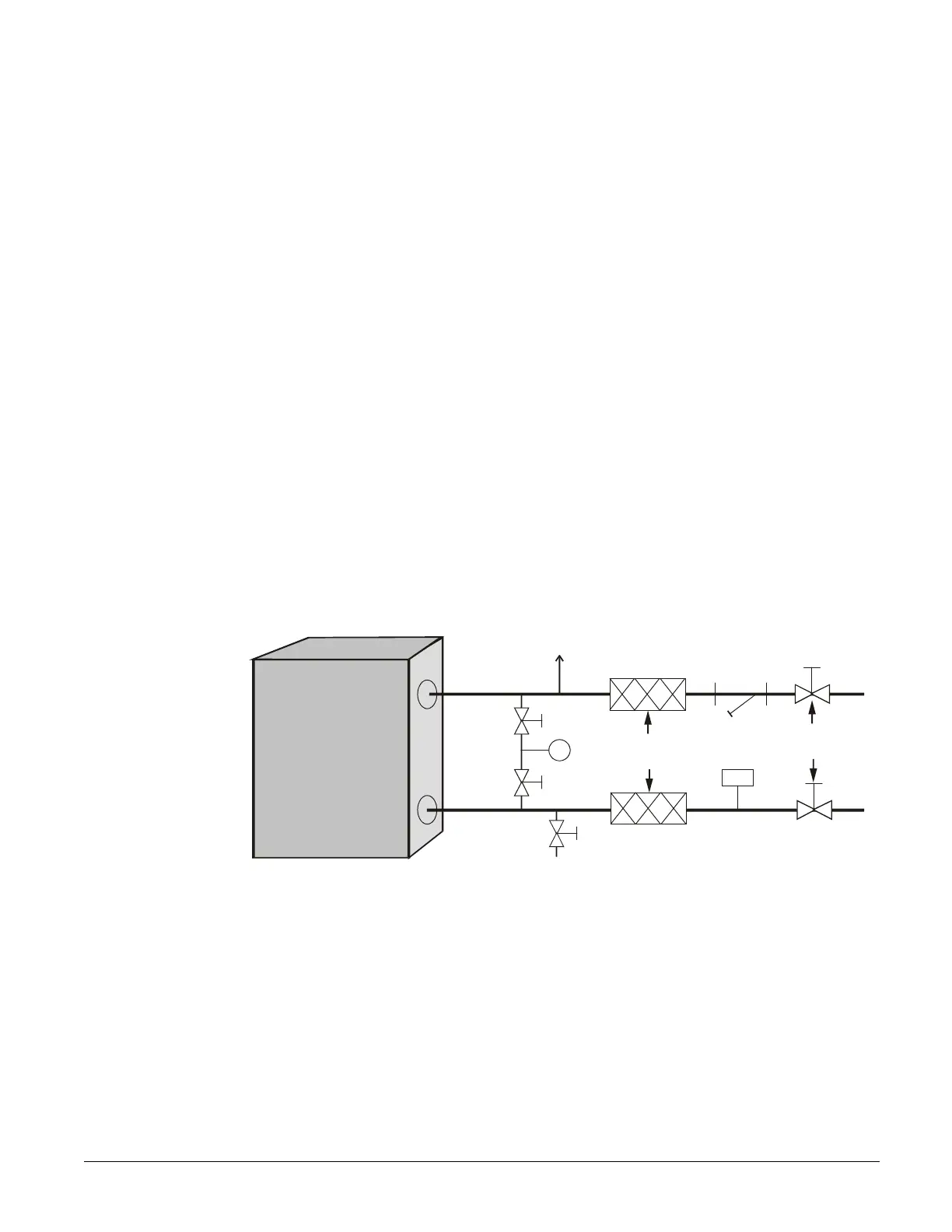

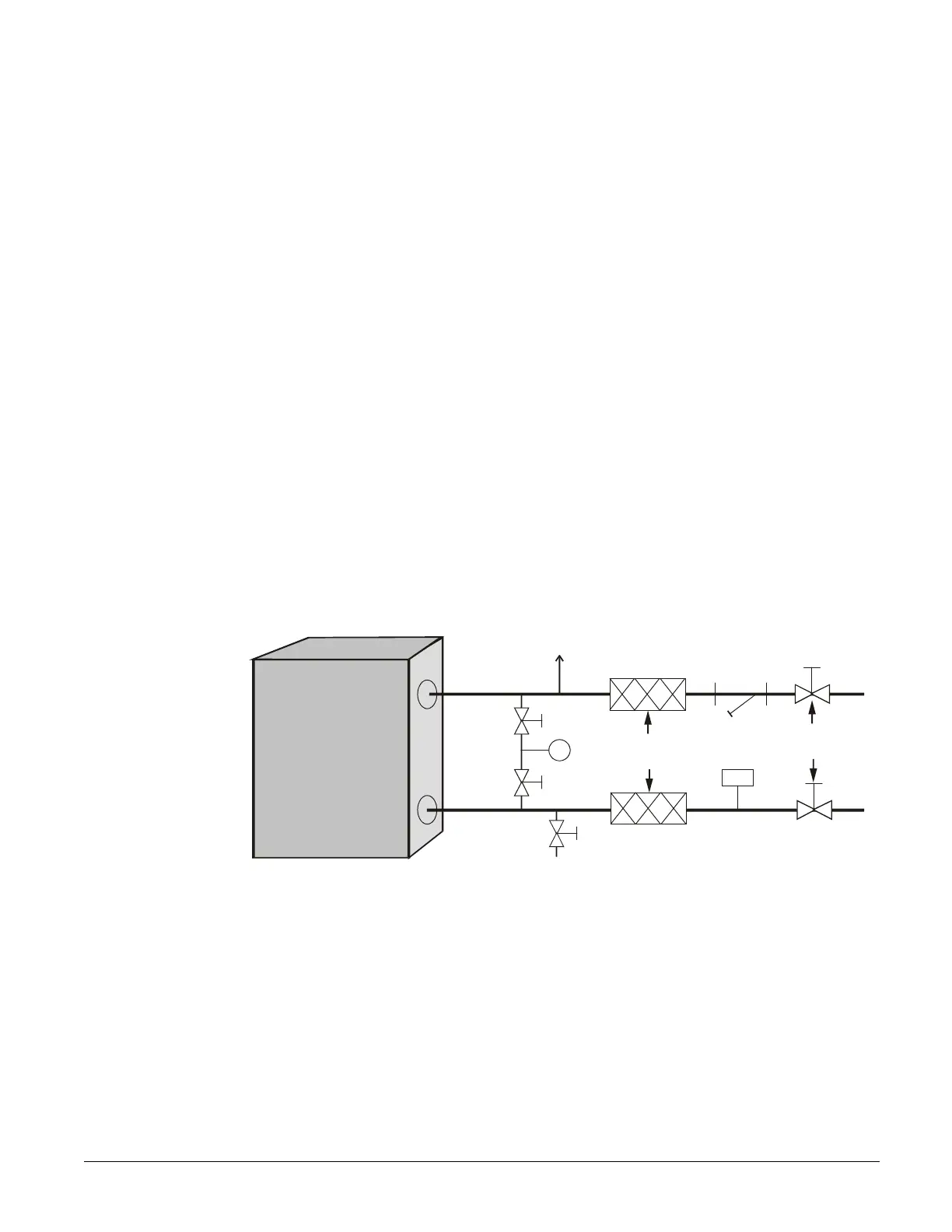

Figure 4, Typical Field Evaporator Water Piping

Air

Vent

Flow

Switch

Vibration

Eliminators

Drain

Outlet

Inlet

P

Isolation

Valves

Strainer

System Volume

It is important to have adequate water volume in the system to provide an opportunity for the chiller

to sense a load change, adjust to the change and stabilize. As the expected load change becomes

more rapid, a greater water volume is needed. The system water volume is the total amount of water

in the evaporator, air handling products and associated piping. If the water volume is too low,

operational problems can occur, including rapid compressor cycling, rapid loading and unloading of

compressors, erratic refrigerant flow in the chiller, improper motor cooling, shortened equipment life

and other undesirable occurrences.

Loading...

Loading...