Product Manual ALR2-3 ALR 110F – 150F 7

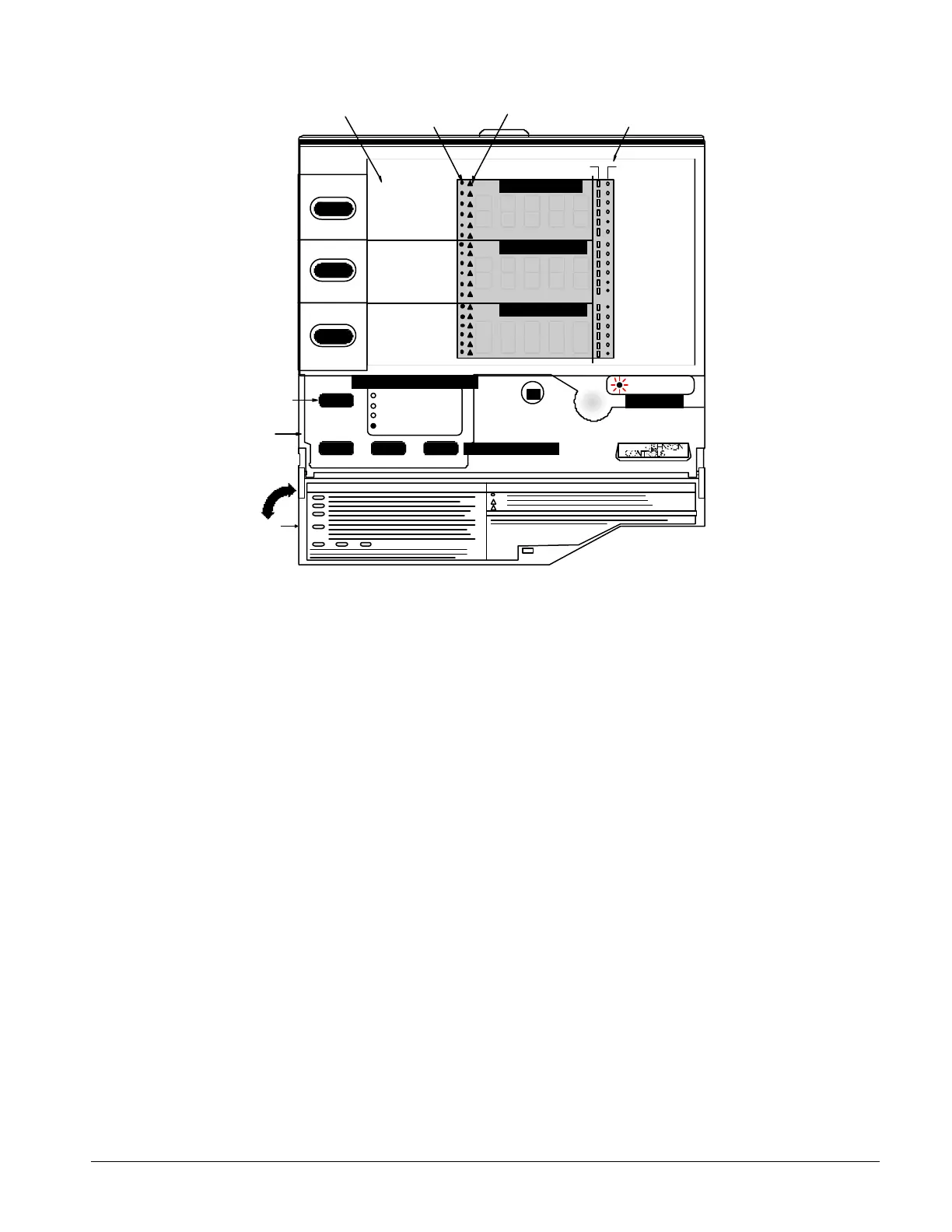

Figure 2, Zone Terminal Configuration

MONITOR

ADJUST

TIME SCHEDULE

PASSWORD

ENTER

Compressor 1

Compressor 2

Stage 3

Stage 4

Solenoid #1

Frzstat#1Alm

Frzstat#2Alm

MinLowPres#1

MinLowPres#2

Occupied

Flow Failure

OA Lockout

Cir#2Lead=On

Pmp/Stp #1=0

Lvg Water Temp

Evap Pres #1

Evap Pres #2

OA/AI3 Input

LvgWtr RBnd SP

Contrl Band SP

Actual Lvg SP

Unoccpd Lvg SP

OA Lockout SP

Lvg Low Lim SP

SoftSta Capcty

Cir #1 Starts

Cir #2 Starts

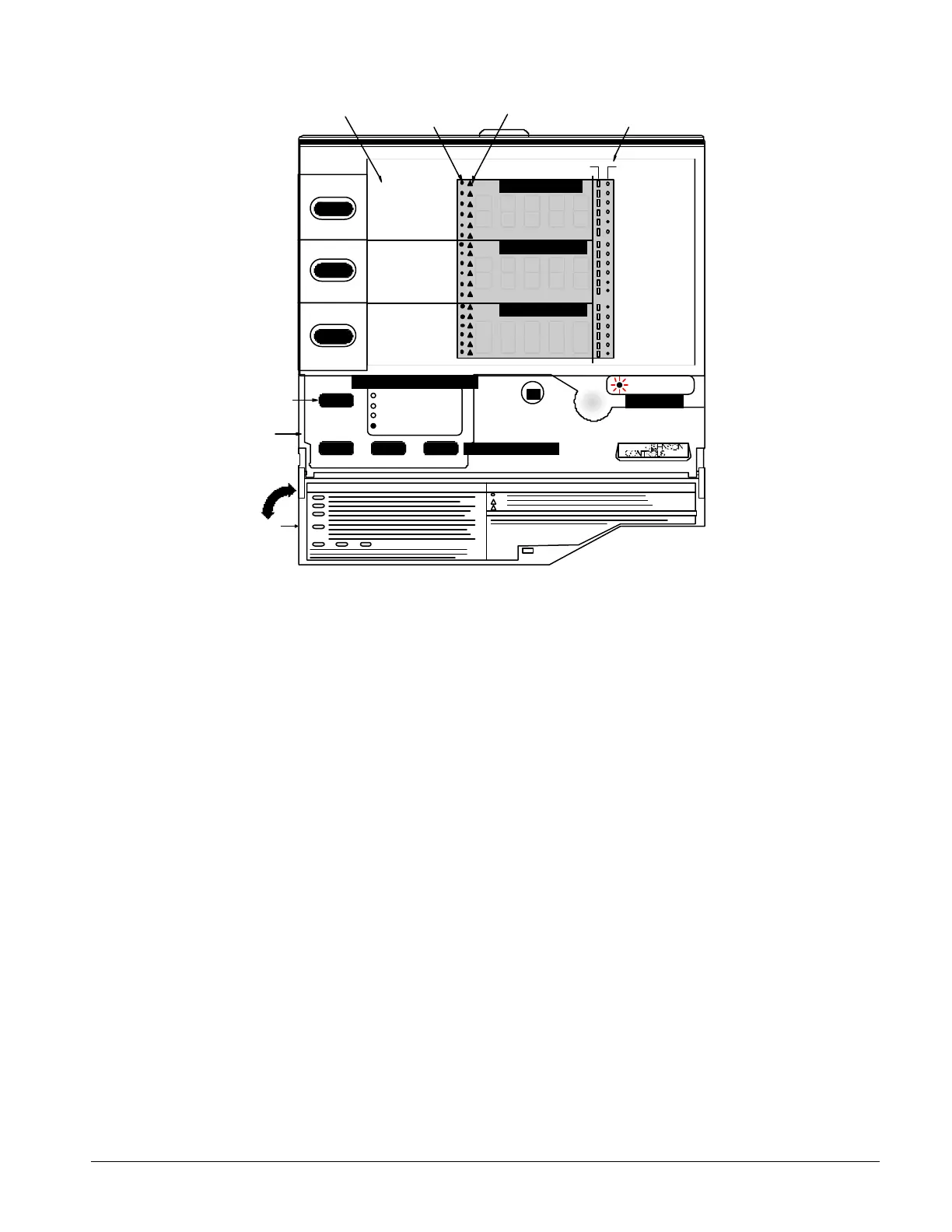

McQuay AGZ/AGR Global Chiller

INSERT 10

ON OFF

Display

Button 1

Mode

Selector

Panel

Mode

Selector

Button

2

AGZ-AGR

Display Indicator Dot

On/Off Status

3

Operating Mode Indicator

Up/Down Arrow Keys

Door

Display Item List

Warning Signal

ALARM

OA/AI3 HiLimSP

OA/AI3 ResetSP

Display Area 11

Display Area 21

Display Area 31

Alarm Light

Lvg Water SP

% Unit Load

SoftStart Time

Pmp/Stp #2=0

Solenoid #2

Stage 5 Opt.

Stage 6 Opt.

Optional MicroTech Control

The exclusive MicroTech microprocessor control is common throughout McQuay equipment. The

interface is a 12 key keypad and 2-line, 32 character backlit liquid crystal display. The MicroTech

continuously performs self-diagnostic checks on all system temperatures, pressures, and safeties, and

will automatically shut down a circuit or the entire unit if a fault condition occurs. The cause, time,

and date of the occurrence is recorded and can be displayed. The seven previous incidents are kept

in memory for service reference.

If a fault occurs, the controller takes preventive measures in an effort to keep the unit operating;

staging down capacity, activating a pre-alarm signal, and automatically switching to the alarm menu on

the display. Pre-alarms are self-clearing when the fault condition is no longer present.

Critical shutdown alarms such as high condenser pressure (with mechanical back up), freeze

protection, oil pressure (with mechanical back up), and low evaporator pressure are manual reset and

must be cleared at the keypad to resume operation.

Choose the MicroTech control and Open Protocol options to interface with virtually any building

management system and perform remote monitoring and control by hard wiring or modem. A nominal

site license fee is required for a Building Automation System (BAS) interface.

A single chiller can connect directly to the BAS. Two or more units will require an Open Protocol

Panel (OPM) for connection.

Thirty feet of sensor cable is included, rolled up in the control panel, on remote evaporator models.

The cable can be field spliced for a total run not to exceed 75 feet.

Loading...

Loading...