Page 14 of 24 / IM 439

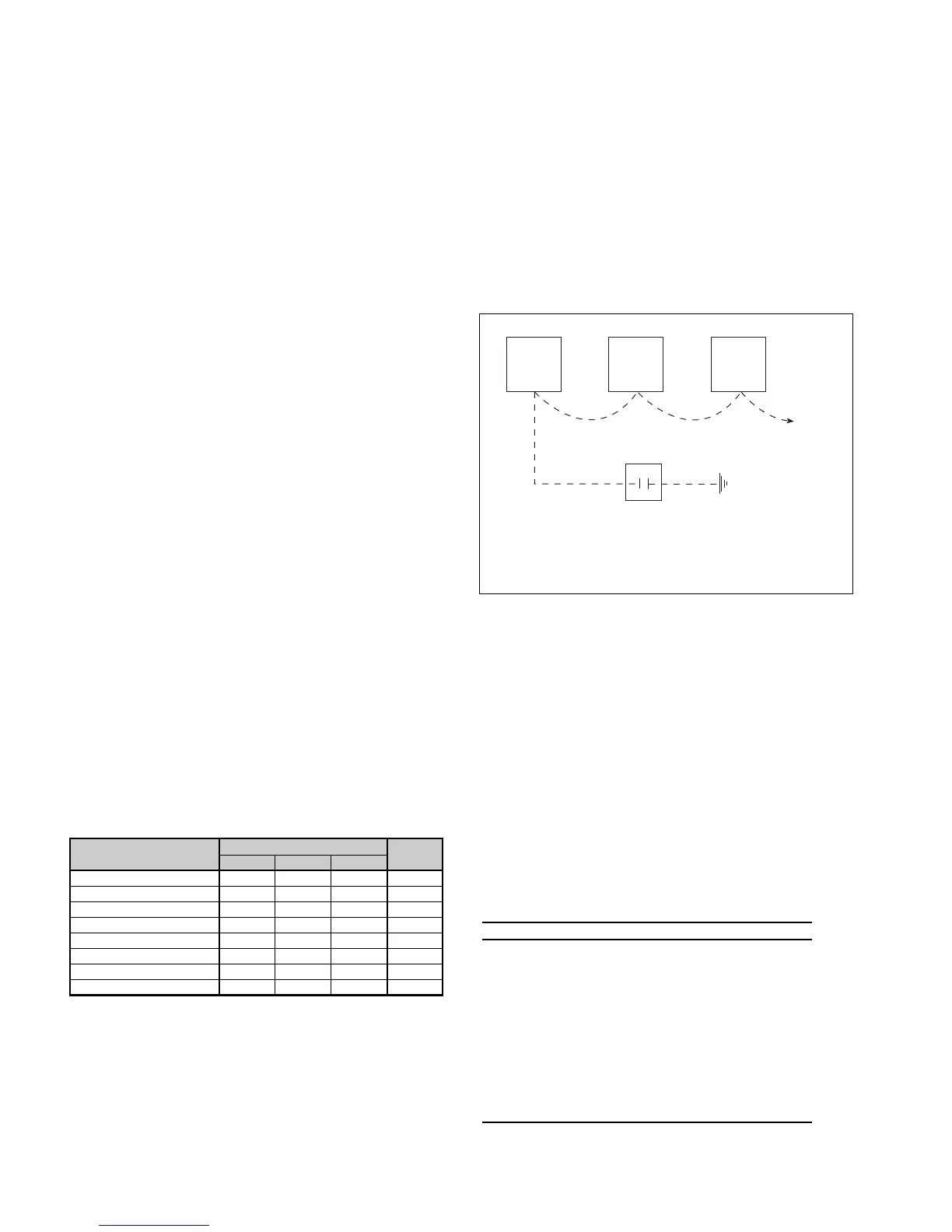

14-Position Terminal Strip

Pin Designation Description

1CTransformer ground (Ovac)

2RTransformer supply (24vac)

3V-DC power connection

4PPump request output

5A Alarm fault output

6UUnoccupied input

7LLoad shed input

8ERemote shutdown input

9F+DC power connection

10 Y1 Occupied cooling mode input

11 W1 Occupied heating mode input

12 G Fan only input

13 W2 Unoccupied heating mode input

14 O Tenant override input

Mark IV/AC Sequence of

Operation

The Mark IV/AC control board has built-in night setback

operation. A “grounded” signal to the “U” terminal on the low

voltage terminal strip puts the unit into the unoccupied mode

for night setback operation. The fan shuts off and the unit is put

under control from the night setback terminal on the thermo-

stat, W2 on single compressor and W3 on dual compressor

Ground

Unit

3

To

Additional

Units

Time

Clock

Unit

2

Unit

1

Unit Operation

General

Each unit has a printed circuit board control system. The low

voltage output from the low voltage terminal strip on the control

board is always 24 volts DC (direct current). Terminals C and

R on the low voltage terminal strip supply 24 volts AC power.

The unit has been designed for operation with a 24 volt

mercury bulb type wall thermostat or a microelectronic wall

thermostat selected by the manufacturer. Do not operate the

unit with any other type of wall thermostat.

Table 3.

LEDs

FAULT

INDICATION

Yellow Green Red

OUTPUT

Normal Mode Off On Off Off

High Pressure Fault Off Off Flash On

Low Temperature Fault* Flash Off Off On

Condensate Overflow On Dim Off On

Brown-out Off Flash Off On

Load Shed Off Off On Off

Unoccupied Mode On On Off Off

Unit Shutdown Off Flash Off On

*In heating mode only.

Mark IV/AC Control Units

Single compressor units have a single Mark IV/AC circuit

board and dual compressor units have two Mark IV/AC circuit

boards. The refrigerant circuits on dual compressor units

operate totally independent from each other and allow for

total independent operation of each circuit.

The Mark IV/AC circuit board has built-in features such as

random start, compressor time delay, night setback, load

shed, shutdown, condensate overflow protection, defrost

cycle, brownout, and LED/fault outputs.

The 24 volt low voltage terminal strip on each board is set

up so R-G energizes the fan, R-Y1 energizes the compressor

for cooling operation, R-W1 energizes the compressor and

reversing valve for heating operation. The reversing valve is

set up to be energized in the heating mode. The circuit board

has a fan interlock circuit to energize the fan whenever the

compressor is on if the thermostat logic fails to do so.

The Mark IV/AC control board has a lockout circuit to stop

compressor operation if any one of its safety switches opens

(high pressure switch and low pressure switch). If the low

temperature switch opens, the unit will go into the cooling

mode for 60 seconds to defrost any slush in the water-to-

refrigerant heat exchanger. After 60 seconds the compressor

is locked out. If the condensate sensor detects a filled drain

pan, the compressor operation will be suspended only in the

cooling mode. The unit is reset by opening and closing the

disconnect switch on the main power supply to the unit in the

event the unit compressor operation has been suspended

due to low temperature (freezestat) switch, high pressure

switch or low pressure switch. The unit does not have to be

reset on a condensate overflow detection.

The Mark IV/AC control board has a fault output signal to

an LED on a wall thermostat. Table 3 shows for which functions

the fault output is “on” (sending a signal to the LED).

units; day heating and cooling operation is locked out. R-W2

energizes the compressor and reversing valve for heating

operation. Night setback operation can be overridden for two

hours by toggling the fan switch (intermittently closing the R

to O terminals) on the Deluxe Auto Changeover thermostat.

Day thermostat setpoints then control the heating and cool-

ing operation. The Mark IV/AC control system is also set up

for load shed and shutdown operation on receipt of a

“grounded” signal to the “L” and “E” terminals, respectively,

on the low voltage terminal strip (see Figure 16).

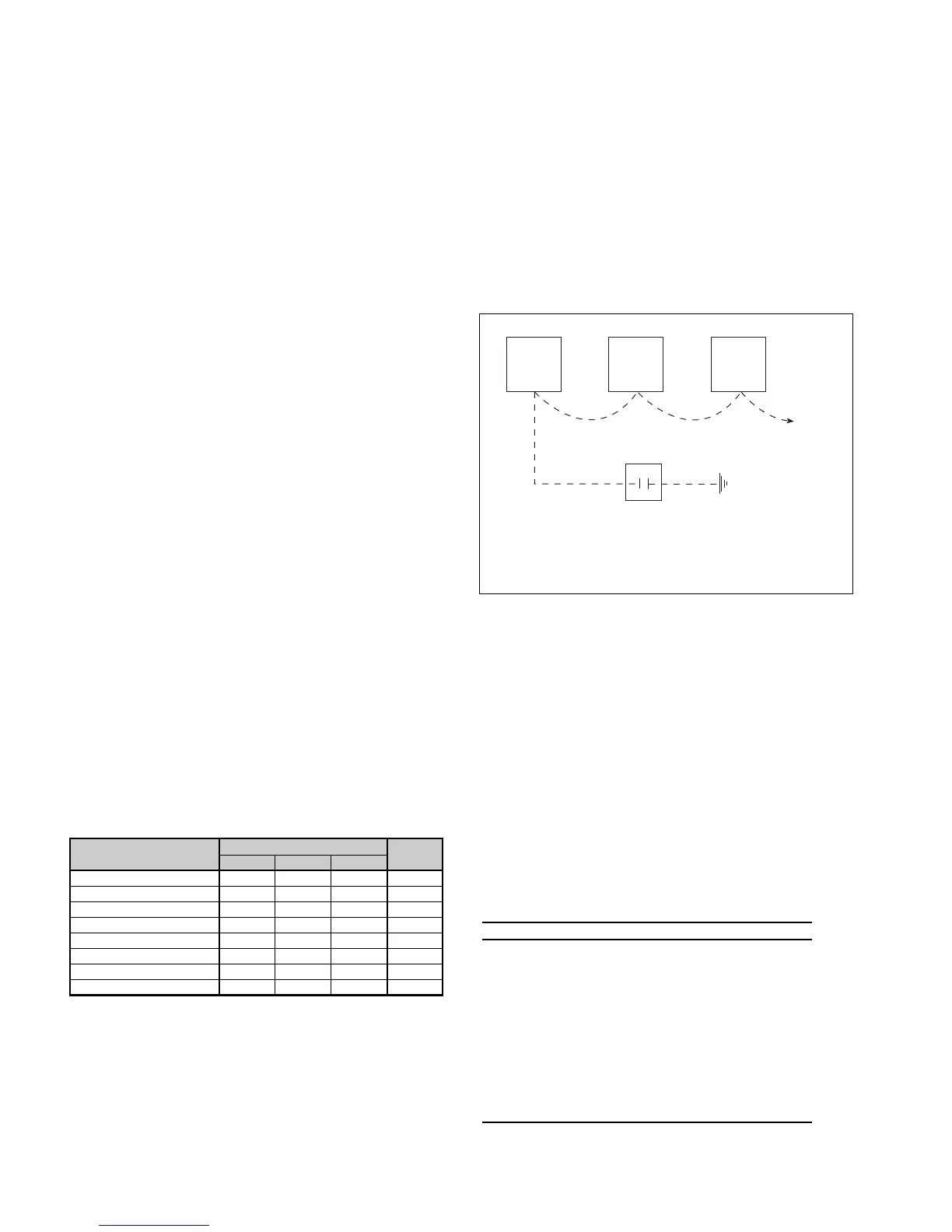

Figure 16.

To activate the unoccupied mode for units on the same clock schedule,

a single wire can be “daisy chained” between units and simply grounded

through the timeclock contacts. The same system can also be done to

activate the load shed and emergency shutdown modes by running

additional wires between units to ground.

The P and C terminals of the Mark IV/AC board are used

for pump restart. These terminals pass a voltage signal

whenever the unit’s compressor is turned on. This signal is

detected by a Pump Restart Relay board (P/N 898-613703X01)

providing a N.O. or N.C. set of contacts for heat pump loop

circulation pump control. When used with the Loop Water

Controller, the relay operation accommodates turning off

circulation pumps during unoccupied periods with a safety

override dependent on, at minimum, one WSHPs need. The

P and C terminals may be “daisy chained” between 200 units

(see page 18).

Loading...

Loading...