-86-

Design & installation Guide For McQuay MDS Multi System

4.3.7 Process Sequence of Air Leakage Test

Main points of testing

Please test as follows:

The Pressure charging must be tested both in liquid pipe and gas pipe.

First step, keep 3.0kg/cm

2

pressure gas for more than 3 minutes---may be can find

big gap;

Second step, keep 15.0kg/cm

2

pressure gas for more than 3 minutes---may be can

find big gap;

Third step, keep 28.0kg/cm

2

pressure gas for more than 24 hours.

Notes: Keep the 28.0kg/cm

2

pressure gas must more than 24 hours.

The pressure can not be more than 28.0kg/cm

2

!

Check the pressure decrease or not

If the pressure remain the same, then it is OK;

If the pressure decrease, then we should find out the leak gap.

If the ambient temperature when pressure is charged is different from the temperature

when observing, the pressure need to be modified as follows:

Modified value = (temperature when pressure is charged- temperature when

observing)x 0.1; e.g.: when pressure is charged to 28.0kg/cm

2

and the ambient

temperature is 25 ; after 24 hours, the pressure is 27.5kg/cm

2

and the tempera-

ture is 20 , then you can have a conclusion that it is OK.

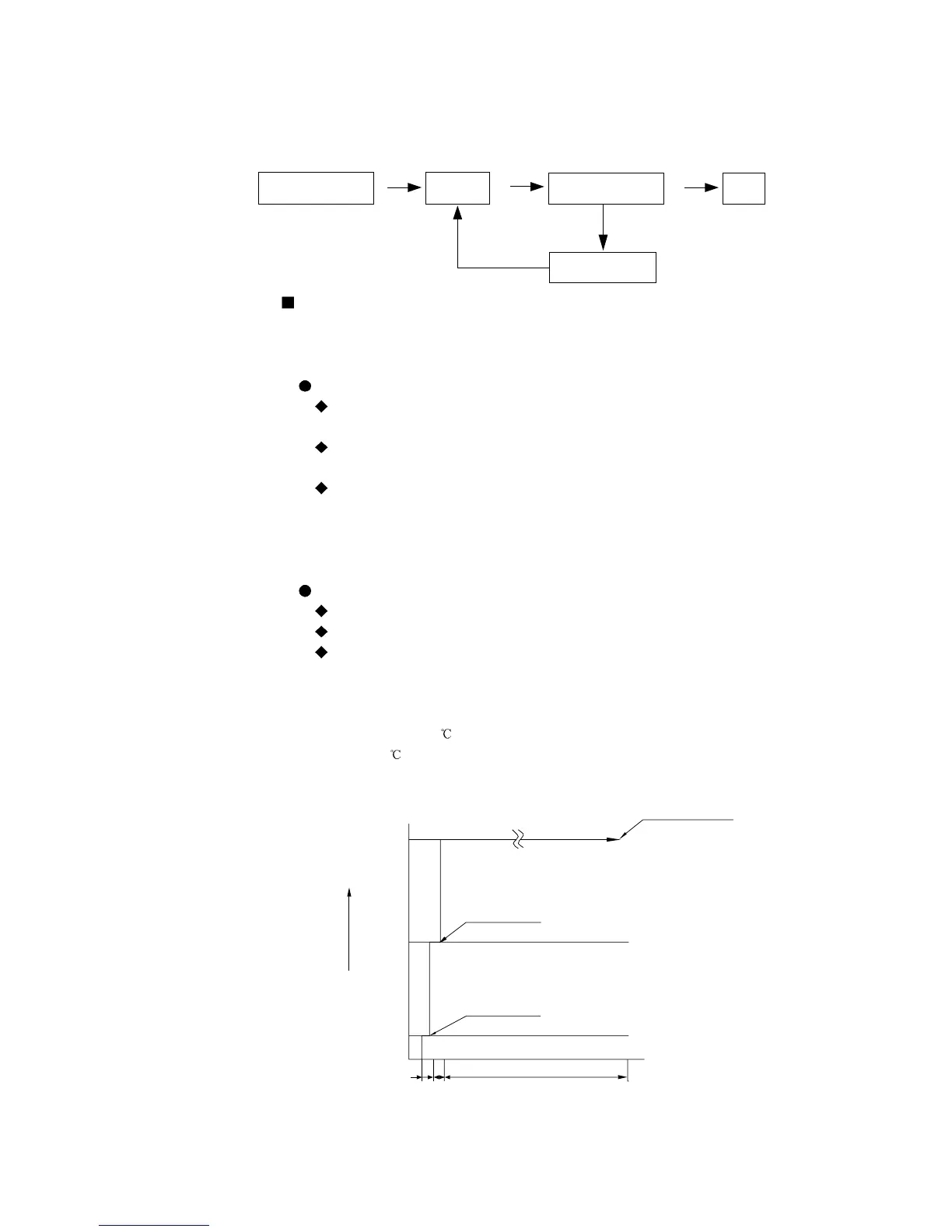

24 hours

First step

Pass

Work flow

Second step

Pass

15kg/cm

2

x 3min.

3kg/cm

2

x 3min.

30kg/cm

2

28kg/cm

2

3kg/cm

2

0kg/cm

2

15kg/cm

2

Third step

3min. 3min.

Pressure

24 hours later, if the

pressure remains to

28kg/cm

2

, then pass

Pass

No

yes

Pressure

charging

Pass

check and

maintain it

refrigerant piping

assembly finished

is the pressure

released?

Loading...

Loading...