The triple evacuation method is recommended and is par-

ticularly helpful if the vacuum pump is unable to obtain the

desired 1 millimeter of vacuum. The system is first evacuated

to approximately 29 inches of mercury. Enough refrigerant

vapor is then added to the system to bring the pressure up

to zero gauge pressure. Then the system is once again

evacuated to approximately 29 inches of mercury. This is

repeated 3 times. The second pull down will remove about

90% of that remaining from the first pull down and after the

third, only

1/10

of 1% non-condensables will remain.

REFRIGERANT CHARGING

The

McQuay

centrifugal chillers normally use R-12, or R-500

refrigerant; therefore, it is recommended that the operator

check the unit nameplate to assure the correct refrigerant

selection prior to charging or adding refrigerant.

An initial operating charge is made at the factory prior to

shipment. In the event the operator needs to add refrigerant

after the unit is installed, certain precautions should be taken

to protect equipment components. Refrigerant charging lines

must be kept dry, clean and free of non-condensable gases.

Care should be taken in selecting the best charging point in

the unit so as to protect the equipment from damage.

If the entire charge is lost or removed from the unit, recharg-

ing can be accomplished quickly and safely by introducing

the liquid refrigerant directly into the bottom of the evaporator

with the expansion valve manually opened. Both condenser

water and chilled water must be flowing through the respec-

tive vessels to prevent localized freezing. Consult the chiller

nameplate for the proper refrigerant charge.

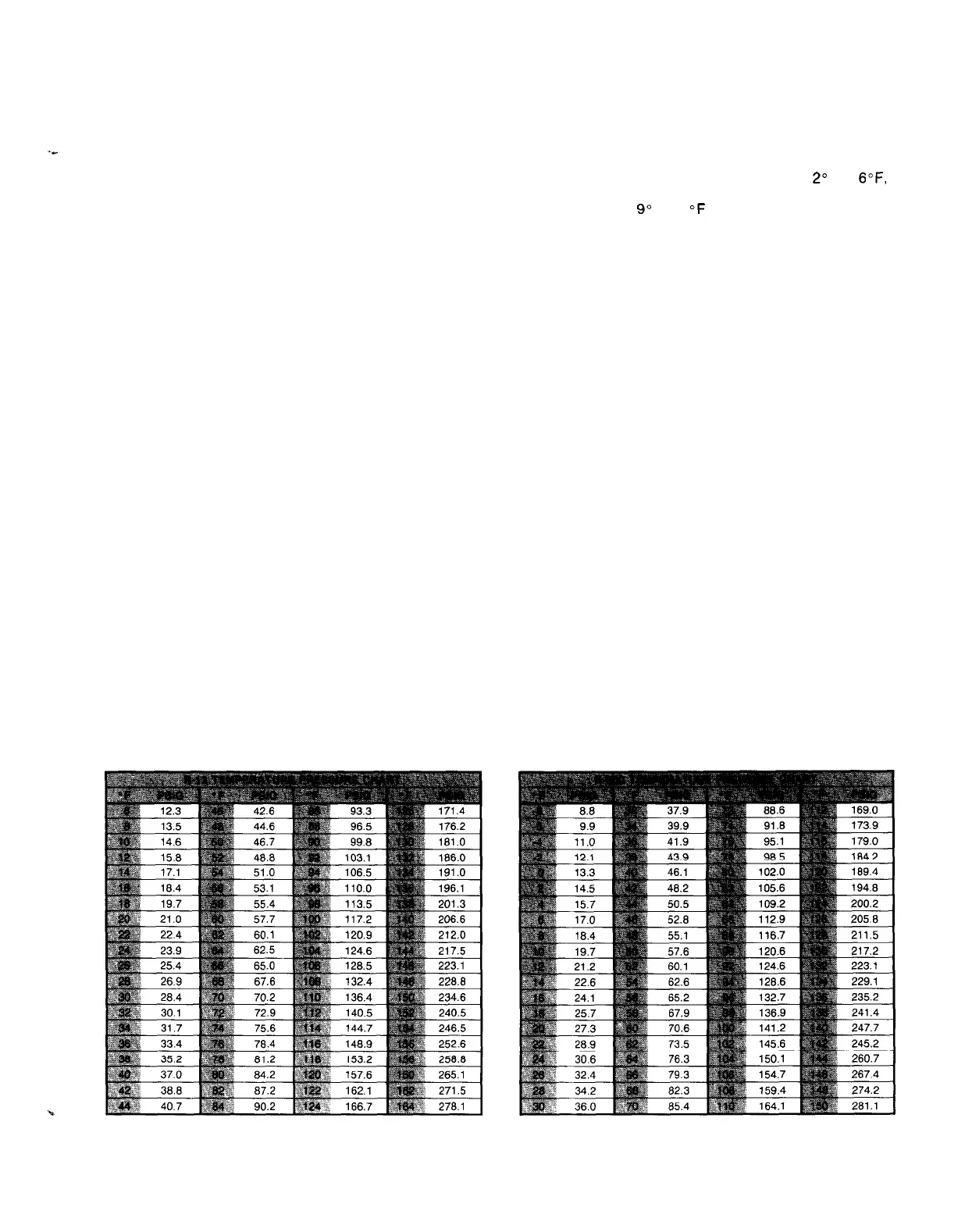

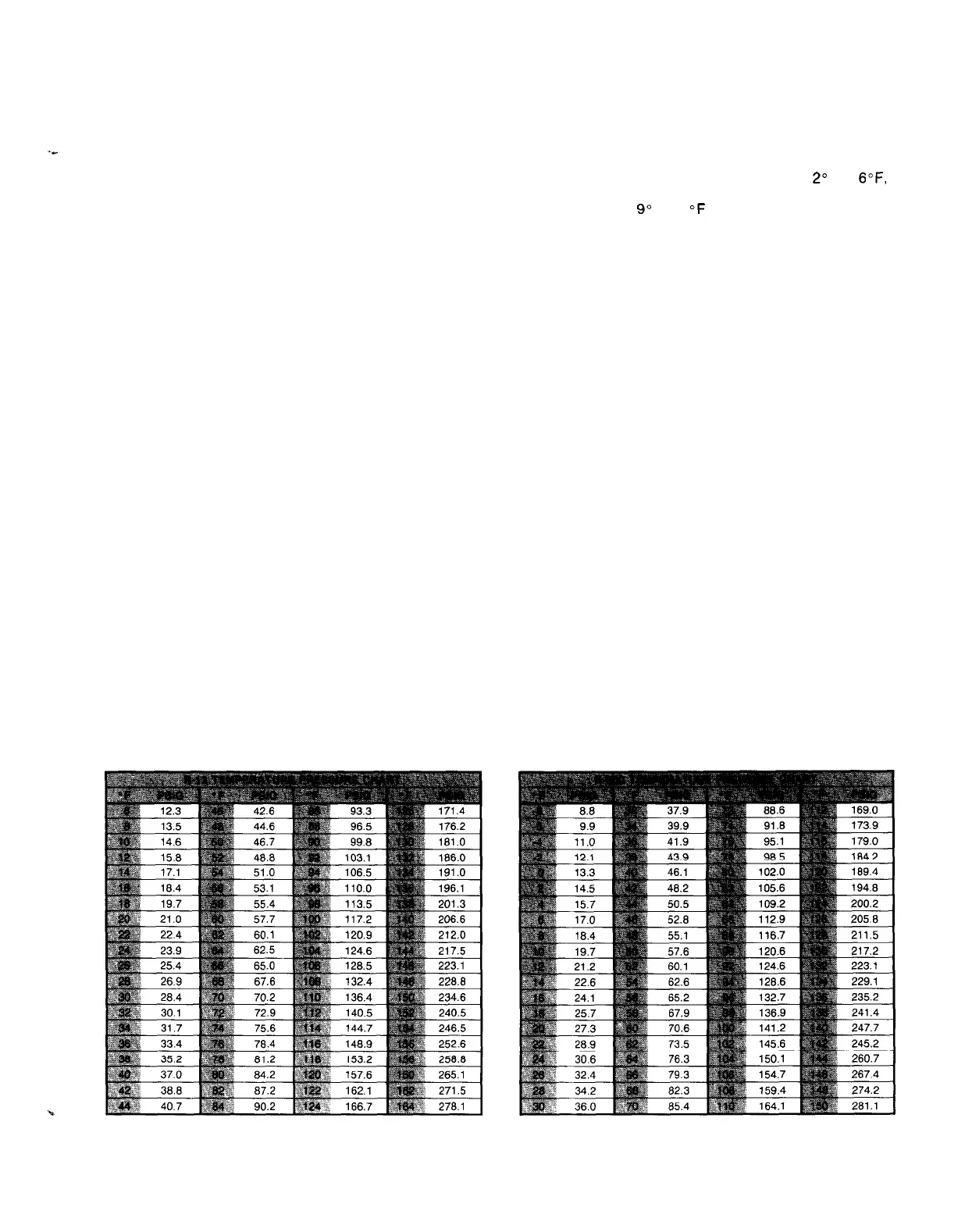

With a near-normal charge in the system, final charging

can best be accomplished with the unit running with the com-

pressor at full load. In this operating mode the unit should

be charged until suction superheat is between

2”

and

6”F,

adjusting the thermal expansion valve as necessary. Con-

tinue charging until

9” to 11

OF

liquid subcooling is obtained

leaving the condenser if the unit is operating at full load. At

less than full load, liquid subcooling will be proportionally less.

PRESSURE RELIEF VALVE REPLACEMENT

Current condenser designs use two relief valves (1 set)

separated by a three-way shutoff valve. In the event one of

the relief valves is leaking on the two valve set, the following

procedures should be followed:

If the valve closest to the valve stem is leaking, back seat

the three-way valve all the way, closing the port to the leak-

ing pressure relief valve. Remove and replace the faulty relief

valve. The three-way shutoff valve should remain either fully

back seated or fully forward for normal operation. If the relief

valve furthest from the valve stem is leaking, front seat the

three-way valve and replace the relief valve and replace the

relief valve as stated above.

EQUIPMENT WARRANTY

Each PEH/PHH centrifugal chiller manufactured by McQuay

startup or 18 months from date shipped by the company,

carries a standard limited warranty. This warranty covers

whichever comes first.

repair or replacement of component parts which prove

defec-

For a complete description of this warranty refer to the

war-

tive in material or workmanship within 12 months from initial

ranty form furnished with the equipment.

REFRIGERANT CHARTS

FIGURE 12.

IM 307 I Page

17

Loading...

Loading...