48 WGS 130A to 190A OM WGS-5

Soft Load – (ON/OFF)

Begin Capacity Limit – (Unit %)

Soft Load Ramp – (seconds)

The Soft Load Unit Limit increases linearly from the Begin Capacity Limit setpoint to

100% over the amount of time specified by the Soft Load Ramp setpoint. If the option is

turned off, the soft load limit is set to 100%.

Demand Limit

The maximum unit capacity can be limited by a 4 to 20 mA signal on the Demand Limit

analog input at the unit controller. This function is only enabled if the Demand Limit

setpoint is set to ON.

As the signal varies from 4 mA up to 20 mA, the maximum unit capacity changes linearly

from 100% to 0%. Although the demand limit can call for 0% capacity, this signal will

never cause a running compressor to shut down. Rather, all running compressors will be

held at minimum load, and this may occur at a demand limit value that is actually less than

20mA.

Network Limit

The maximum unit capacity can be limited by a network signal. This function is only

enabled if the unit control source is set to network. The signal will be received through the

BAS interface on the unit controller.

As the signal varies from 0% up to 100%, the maximum unit capacity changes linearly from

0% to 100%. Although the network limit can call for 0% capacity, this signal will never

cause a running compressor to shut down. Rather, all running compressors will be held at

minimum load, and this may occur at a network limit value that is actually less than more

than 0%.

Condenser Pump and Tower Control

Condenser pump and cooling tower control logic requires that the unit be configured as

water-cooled in order to be active. The unit controller controls water-cooled components

such as condenser pumps and tower controls, since there is usually one tower per unit. Air-

cooled equipment, associated with the remote condenser option, is controlled by the circuit

controllers. Remote evaporative condensers require a self-contained, on-board, discharge

pressure control system.

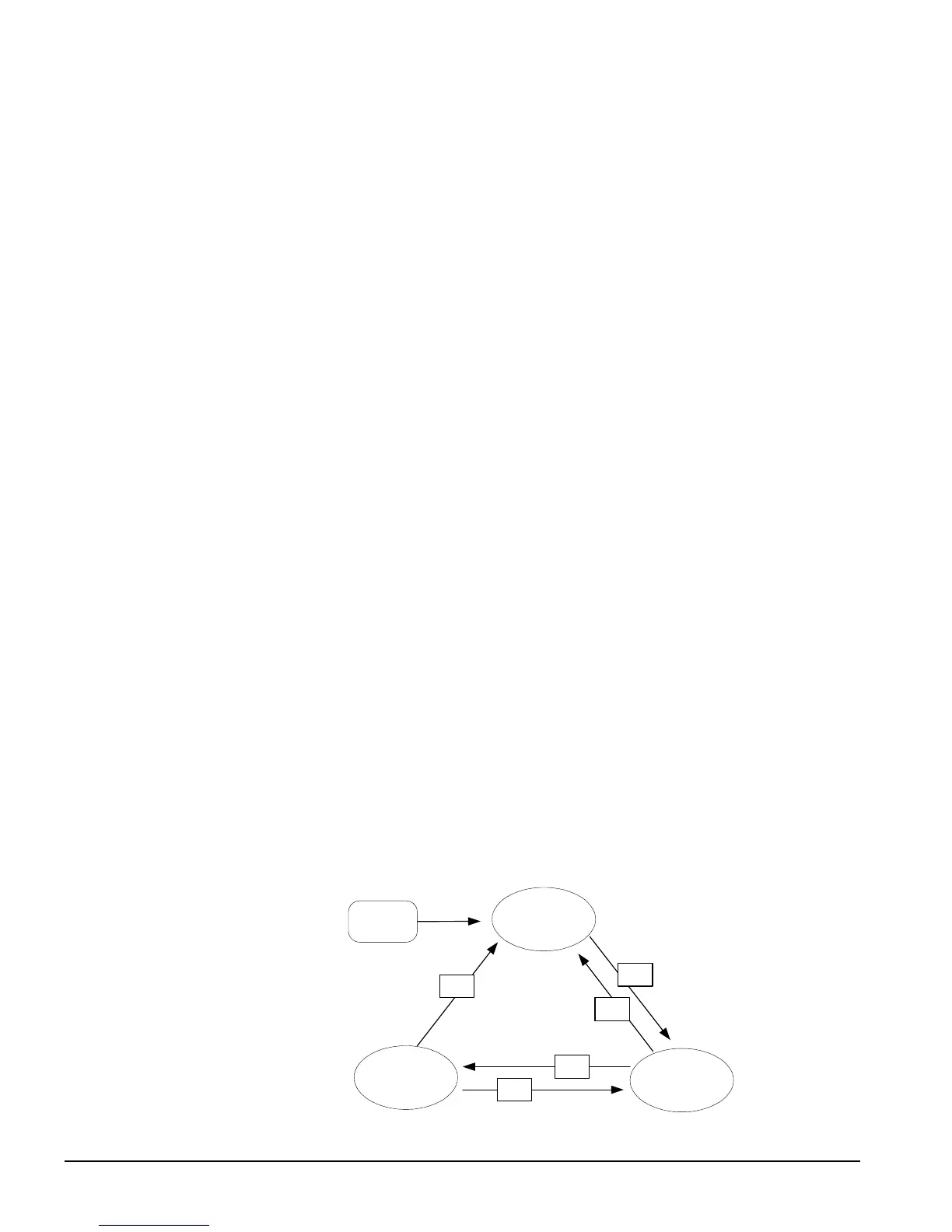

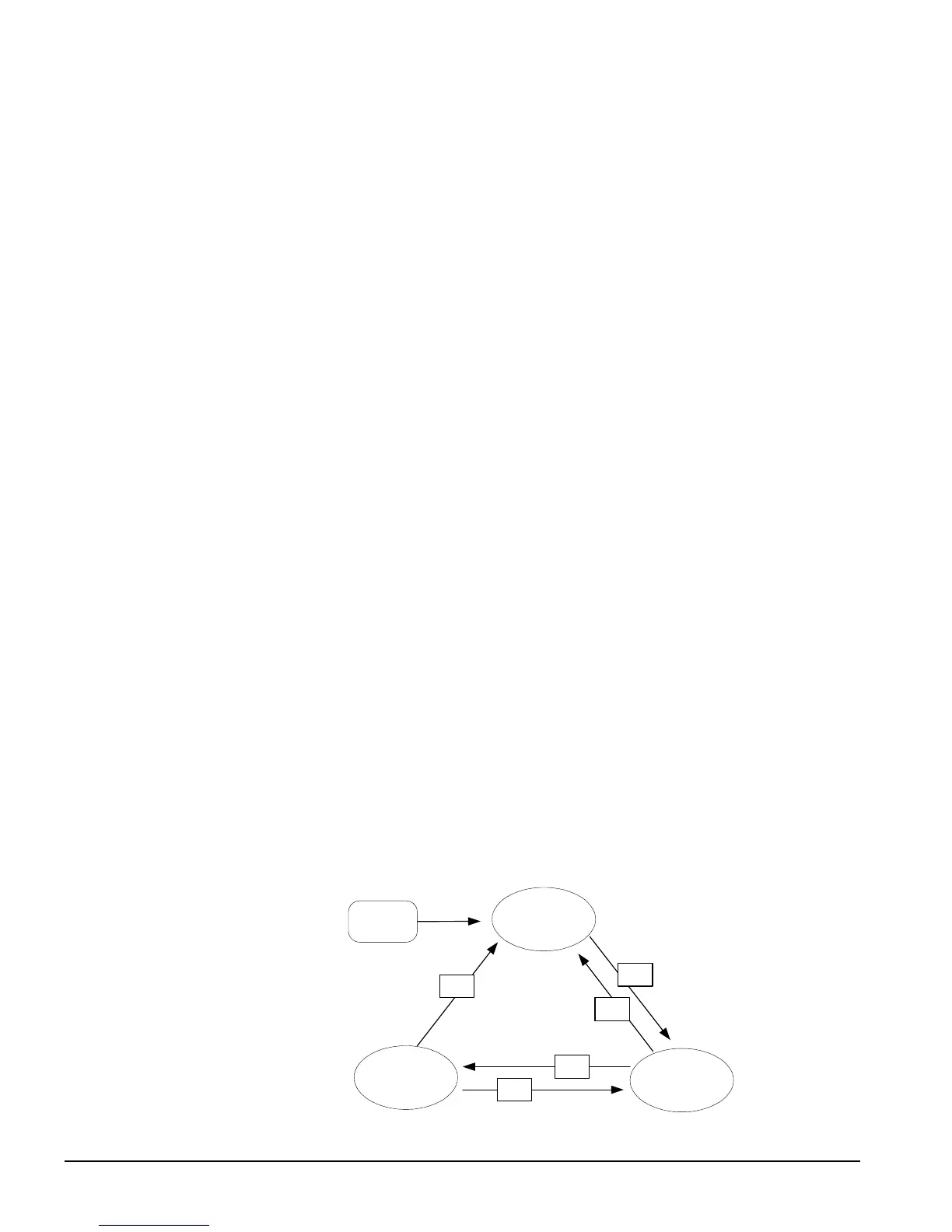

Condenser Water Pump State Control

If the unit is configured as water-cooled, then the condenser pump is controlled by the state-

transition diagram shown below.

Power ON

OFF

RUN

START

T1

T4

T2

T3

Condenser Pump

States

T5

Loading...

Loading...