96 WGS 130A to 190A OM WGS-5

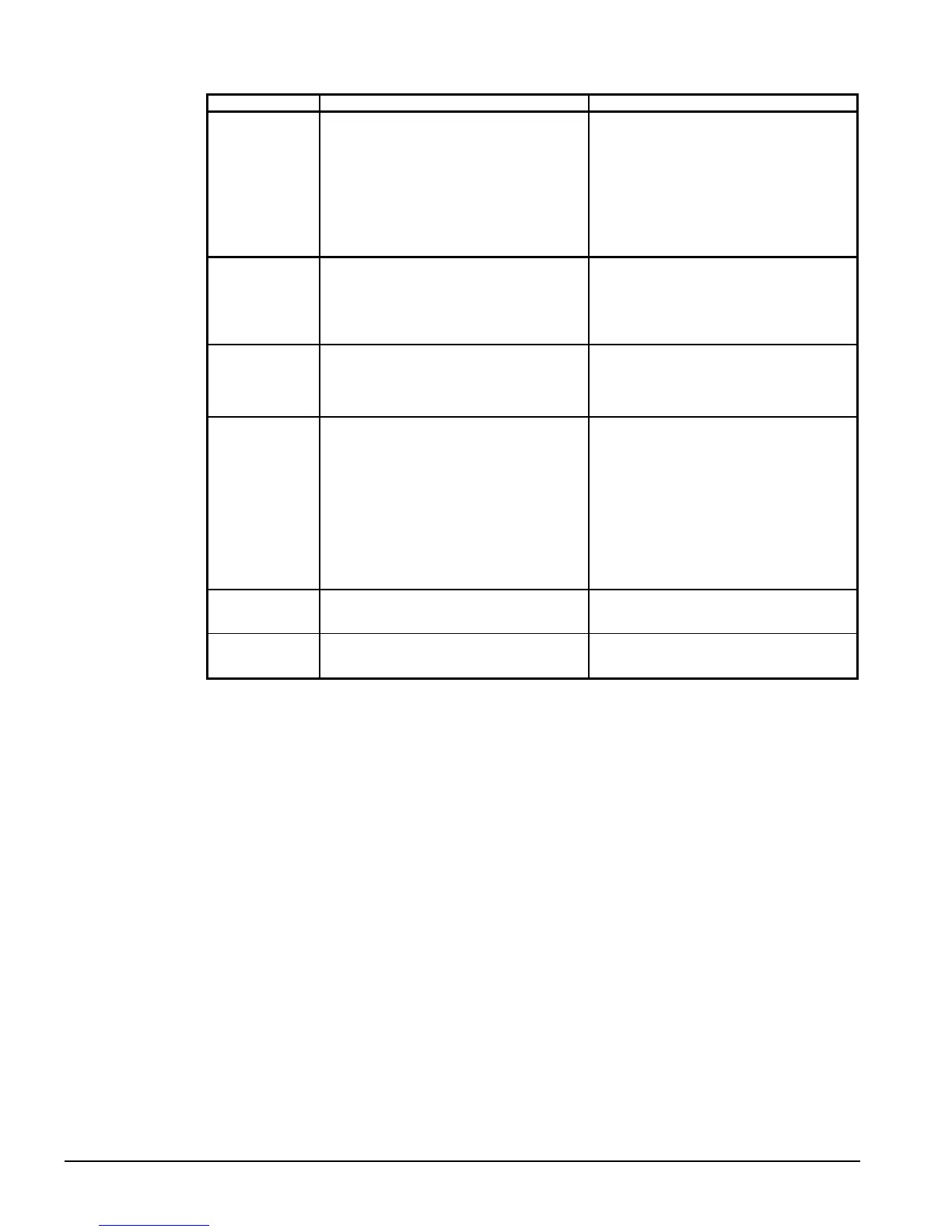

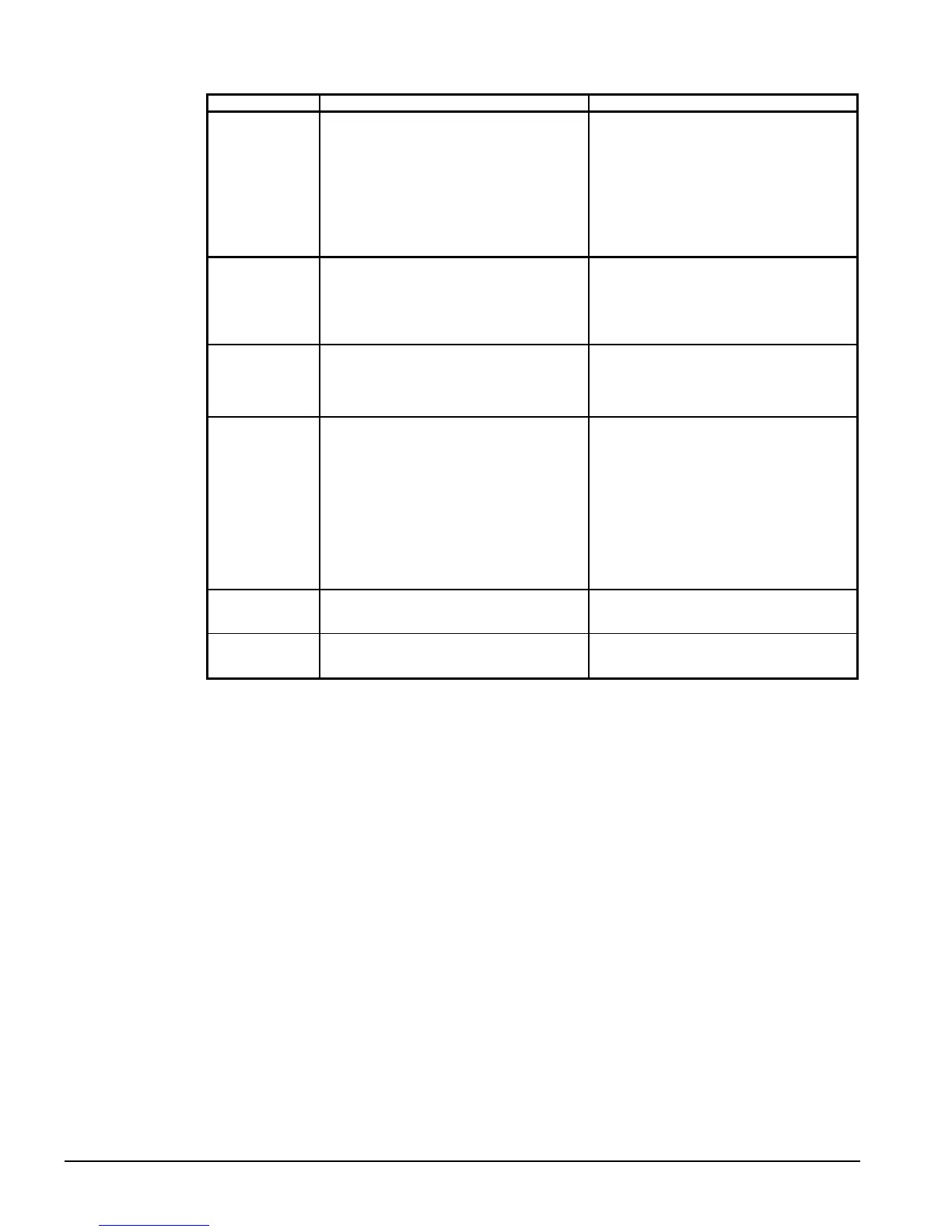

PROBLEM POSSIBLE CAUSES POSSIBLE CORRECTIVE STEPS

Low Suction

Pressure

1. Lack of refrigerant.

2. Evaporator dirty.

3. Clogged liquid line filter-drier.

4. Expansion valve malfunctioning.

5. Condensing temperature too low.

6. Compressor will not unload.

7. Insufficient water flow.

1. Check for leaks. Repair and add charge.

2. Clean chemically.

3. Replace cartridge(s).

4. Check and reset for proper superheat.

Replace if necessary.

5. Check means for regulating condensing

temperature.

6. See corrective steps for failure of

compressor to unload.

7. Adjust flow.

Little or No Oil

Pressure

1. Clogged suction oil strainer.

2. Excessive liquid in crankcase.

3. Low oil level.

4. Flooding of refrigerant into crankcase.

1. Clean.

2. Check sump heater. Reset expansion

valve for higher superheat. Check liquid

line solenoid valve operation.

3. Add oil.

4. Adjust expansion valve.

Compressor

Loses Oil

1. Lack of refrigerant.

2. Velocity in risers too low (A-C only).

3. Oil trapped in line.

1. Check for leaks and repair. Add

refrigerant.

2. Check riser sizes.

3. Check pitch of lines and refrigerant

velocities.

Motor Overload

Relays or Circuit

Breakers Open

1. Low voltage during high load conditions.

2. Defective or grounded wiring in motor or

power circuits.

3. Loose power wiring.

4. High condensing temperature.

5. Power line fault causing unbalanced

voltage.

6. High ambient temperature around the

overload relay

1. Check supply voltage for excessive line

drop.

2. Replace compressor-motor.

3. Check all connections and tighten.

4. See corrective steps for high discharge

pressure.

5. Check Supply voltage. Notify power

company. Do not start until fault is

corrected.

6. Provide ventilation to reduce heat.

Compressor

Thermal Switch

Open

1. Operating beyond design conditions.

2. Discharge valve partially shut.

1. Add facilities so that conditions are within

allowable limits.

2. Open valve.

Freeze Protection

Opens

1. Thermostat set too low.

2. Low water flow.

3. Low suction pressure.

1. Reset to 42°F (6°C) or above.

2. Adjust flow.

3. See “Low Suction Pressure.”

Loading...

Loading...