48

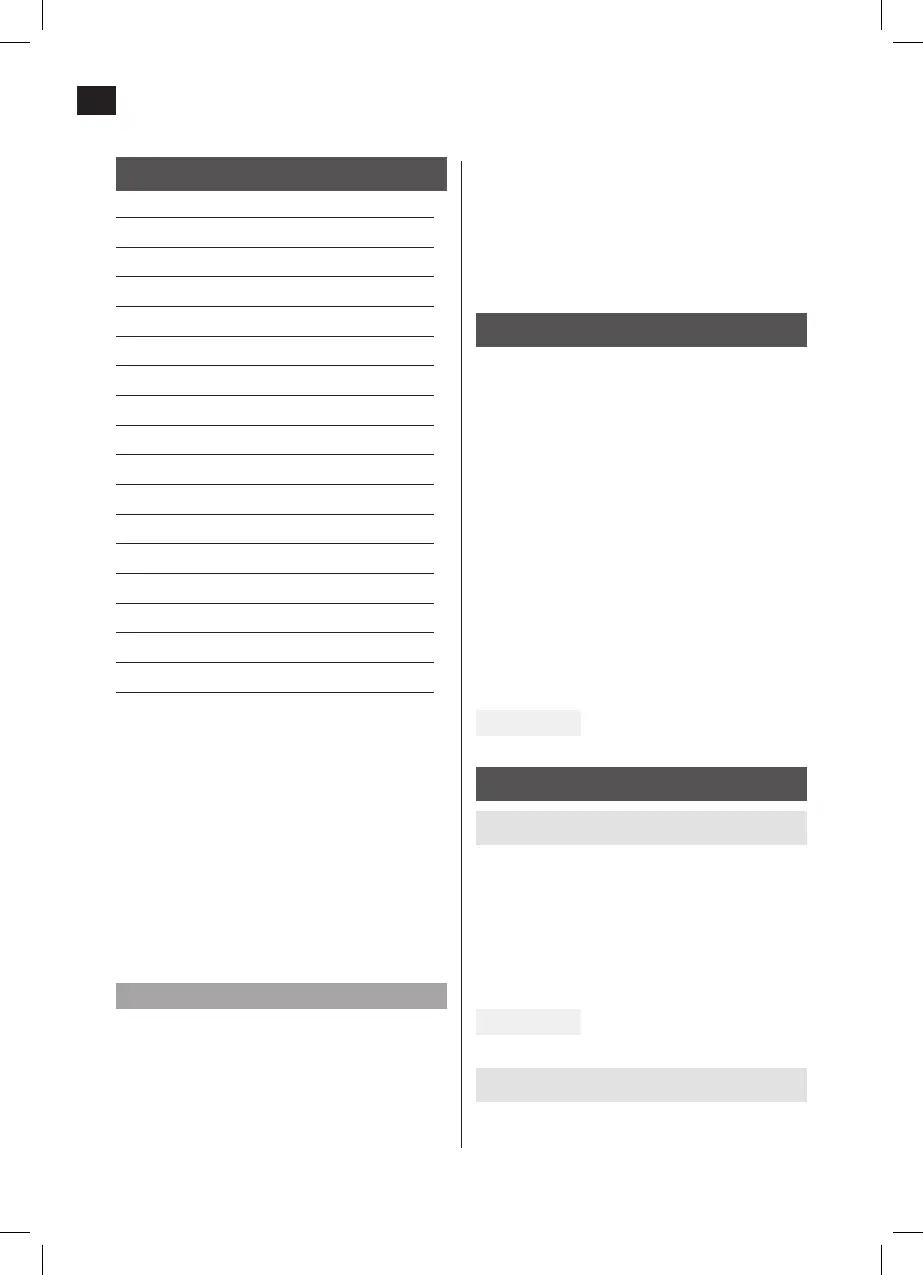

TECHNICAL DATA

Engine type Air cooled, two-stroke

Displacement 25,4 cm³

Output 900W

Idling speed 3000 ± 300/min

Max speed 9000 rpm

Spark plug L8RTC

Volume fuel tank 500 ml

Fuel, mixing ratio 40:1

Axle diameter Ø 24 mm

Working width 380 mm

Trimmer line Ø 2 mm

Weight 4.9 kg

Sound pressure level, LpA 94.5 dB(A)

Sound power level, LwA* 105.8 dB(A), K=3 dB

Sound power level, LwA** 108 dB(A)

Max vibration level F: 5.43 m/s², K=1.5 m/s²

R: 4.79 m/s², K=1.5 m/s²

*Measured, **Guaranteed

F: Front handle, R: Back handle

Always wear ear protection.

The declared values for vibration and noise,

which have been measured according to a

standardised test method, can be used to

compare dierent tools with each other and

for a preliminary assessment of exposure. The

measurement values have been determined in

accordance with ENISO 11806-1:2011.

WARNING!

The actual vibration level when using power

tools may dier from the specied maximum

value, depending on how the tool is used. It is

therefore necessary to determine which safety

precautions are required to protect the user,

based on an estimate of exposure in actual

operating conditions (taking into account all

stages of the work cycle, e.g. the time when

the tool is switched o and when it is idling, in

addition to the start-up time).

DESCRIPTION

1. Shaft coupling

2. Trimmer head

3. Guard

4. Shaft

5. Front handle

6. Back handle

7. Back cover

8. Fuel tank

9. Starter

10. Fuel cap

11. Choke lever

12. Air lter cover

13. Front cover

FIG. 1

ASSEMBLY

Fitting the shaft

1. Press in the bottom part of the shaft (b) as

far as it will go, so that the lock pin (a) goes

in the hole (c) in the shaft. If necessary turn

the bottom part of the shaft (b) back and

forth to make it easier. Check that the lock

pin (a) has gone completely into the hole.

2. Firmly tighten the locking screw (d).

FIG. 2

Fitting the handle

Put the rubber cap (3) on the shaft between the

two arrows. Fit the top part of the handle (2)

Loading...

Loading...