EN

28

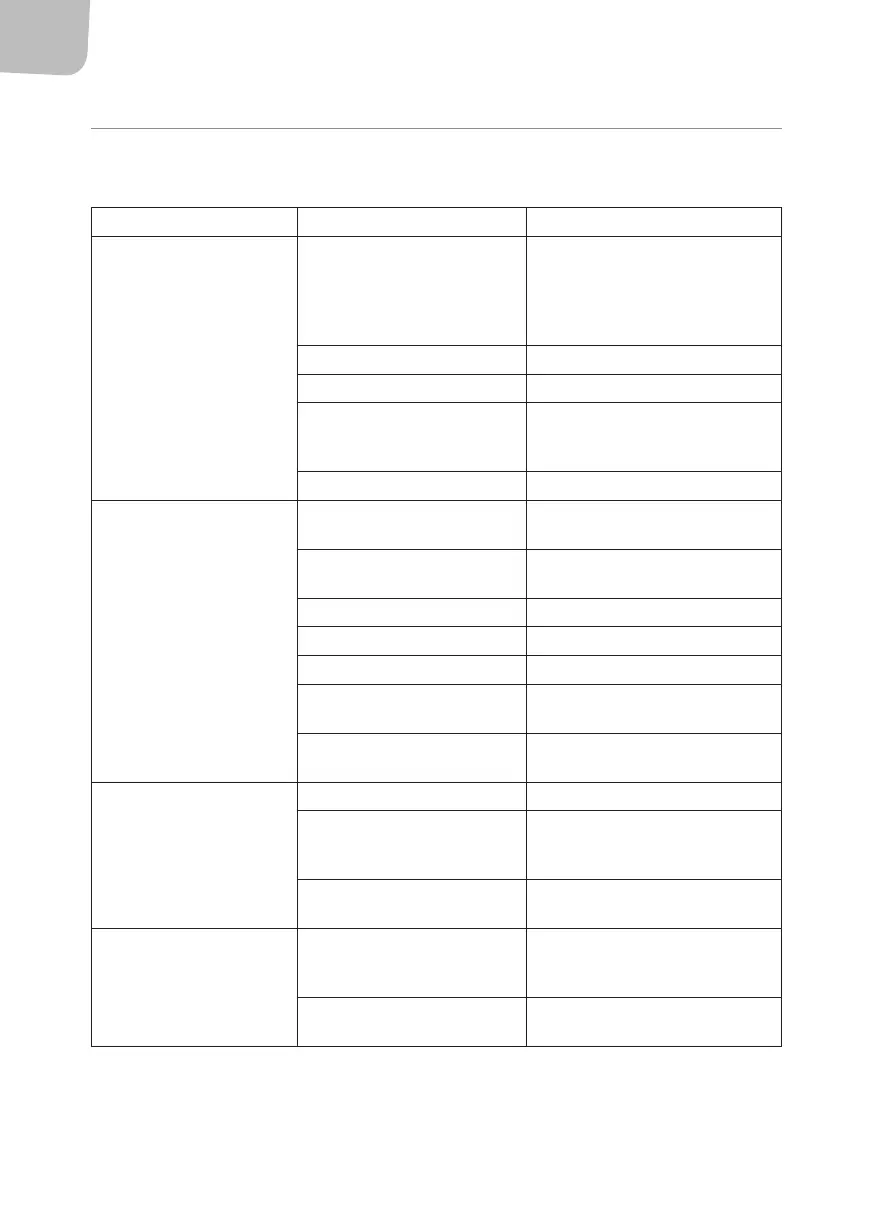

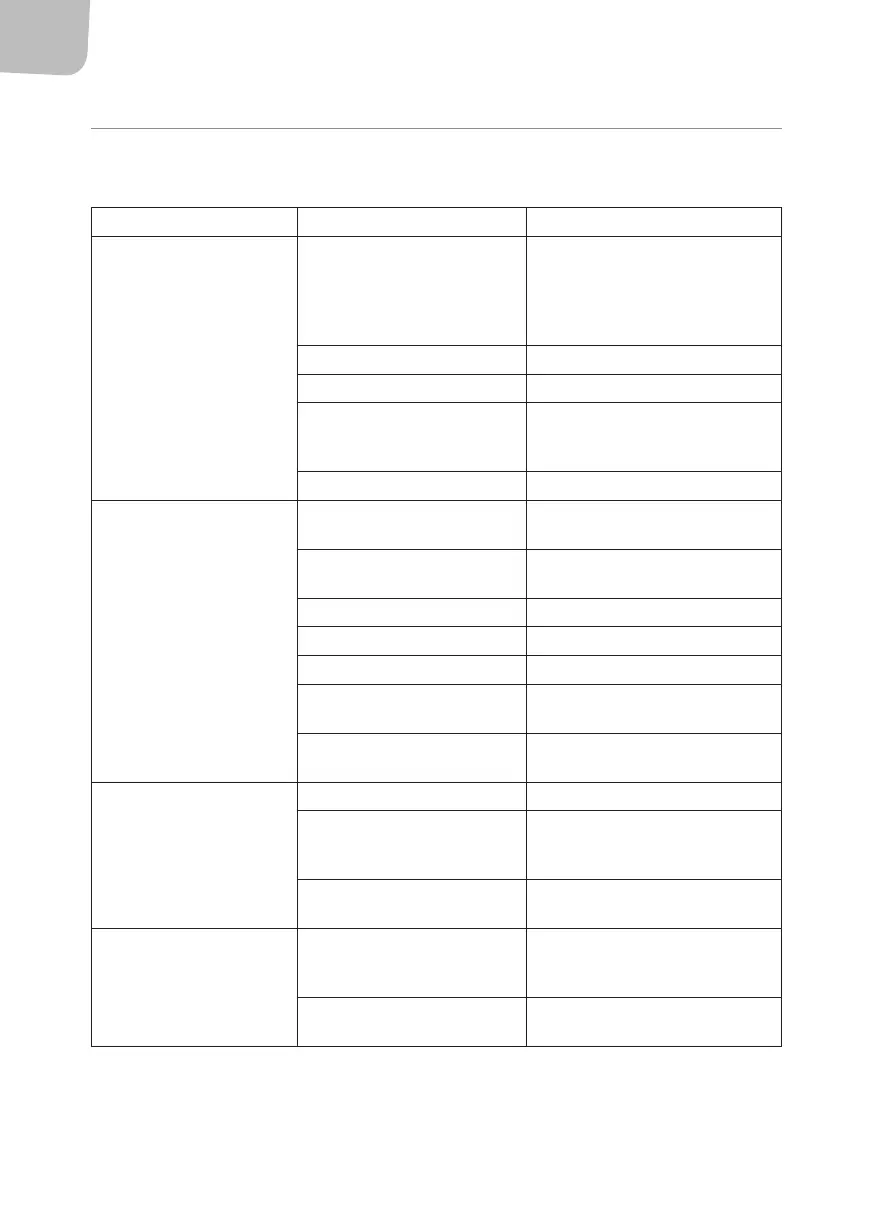

TROUBLESHOOTING

NOTE: Shut-o the pump and disconnect it from the mains supply before checking.

Problem Cause Action

The motor will not start. A. Loose contact in the power

switch.

B. The fuse has tripped.

C. Cable not connected.

D. Phase dropped.

A. Repair or replace.

B. Reset or replace the fuse.

C. Connect the cable.

D. Repair or replace the cable.

Defective capacitor Replace with a new one of the same type.

Faulty bearing. Replace the bearing.

Blocked impeller. Turn the impeller with a screwdriver to

remove the contaminants, or drain and

dismantle the pump housing for cleaning.

Damaged stator winding. Rewind the stator.

The pump runs, but fails to

deliver water.

Incorrect direction of rotation. Reverse the two wires in the connector

(3-phase motor).

The pump is not lled with

water correctly.

Rell the pump with water.

Damaged impeller. Replace the impeller.

Leak on the inlet pipe. Seal or replace the inlet pipe.

Too low water level. Adjust the pump’s installation height.

The water has frozen in the pump

chamber or pipes.

Wait until the pump and pipes have

thawed and then start.

Plastic components damaged because

of too high water temperature.

Replace damaged parts.

Too low pressure. Pump not suited for the type of task. Use a suitable pump.

The inlet pipe is too long, has

too many bends and/or too

small diameter.

Use an inlet pipe with the stated diam-

eter and which is as short and straight

as possible.

Inlet pipe, lter or pump chamber

clogged.

Clear inlet line, bottom valve and/or

pump chamber.

The motor works intermittently

or the stator winding is burned.

The impeller has been blocked or

the pump has been overloaded for

a long time.

Clear the pump chamber and run the

pump within the specied rated ow.

Defective earth, connection fault or

pump damaged by lightning.

Earth the pump correctly, reset the cor-

rect connection and rewind the stator.

Loading...

Loading...