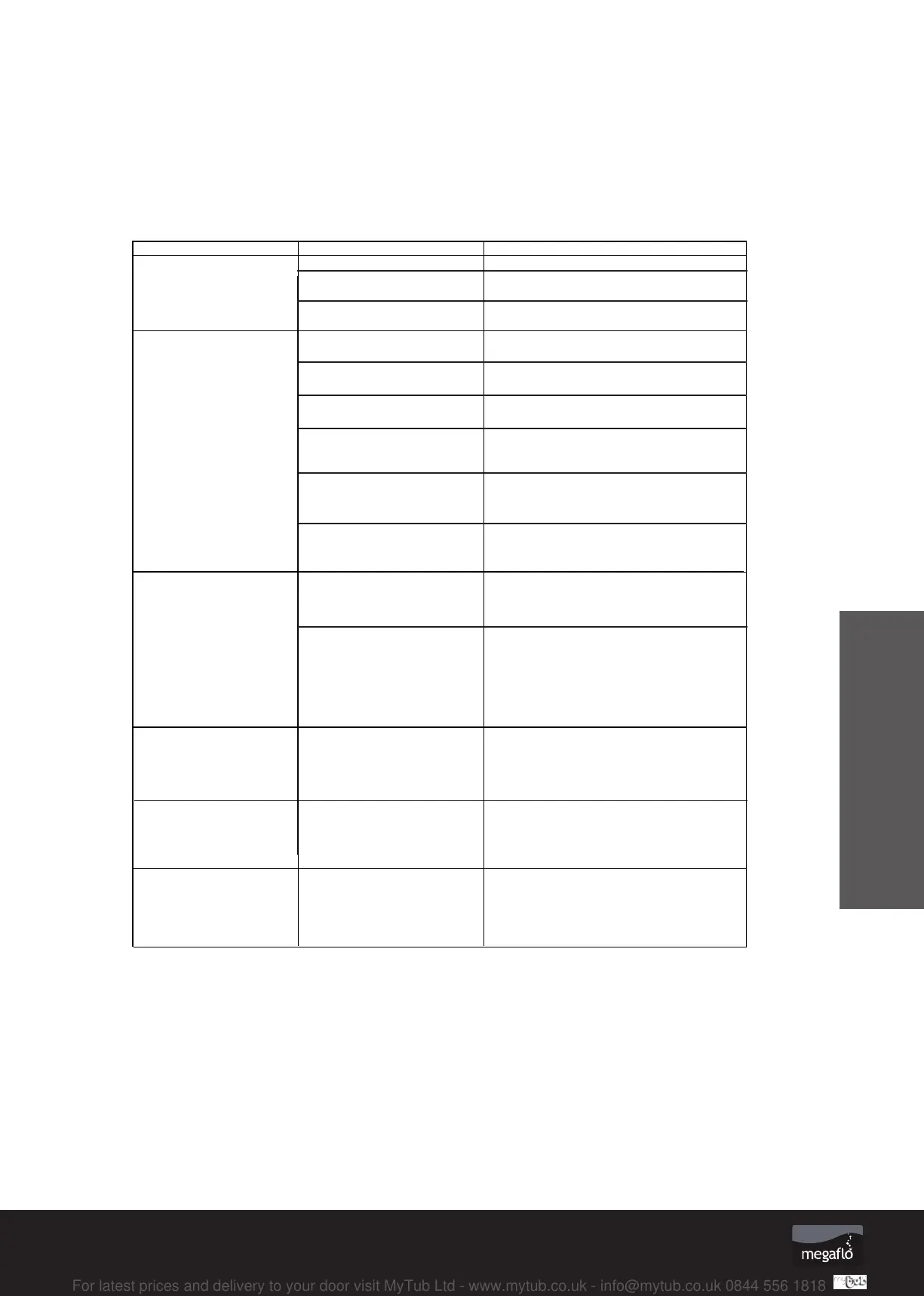

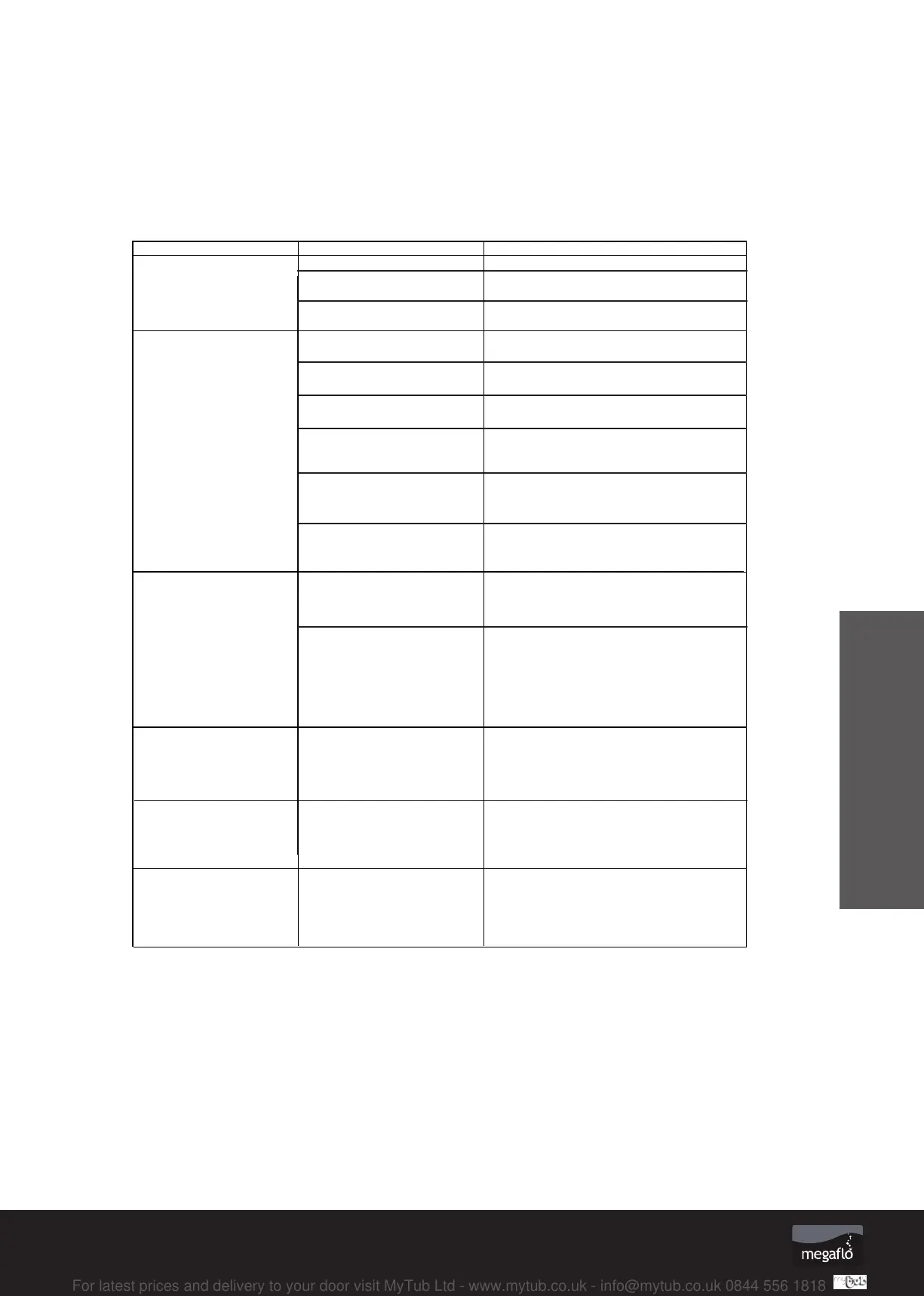

YDEMERESUAC

ELBISSOPTLUAF

1. M a in s water s upp ly off.

2. S tra ine r bloc k e d.

and c lea n (s ee page 28).

3. C old W at er C om b ination

V alve inc orrec tly fitted .

3. C h ec k and re fit as requ ire d.

1. BACK UP immers ion h ea ter

not s witc hed on.

1. C h ec k and s w itc h on.

2. BACK UP immers ion h ea ter

therm al c u t-ou t h as opera ted.

2. C h ec k . R es et by pu s h in g b utto n.

(Figure 16, page 23)

3. IN D IR E C T p rogrammer s et

to C e ntra l H e ating only .

3. C h ec k . S et to a Do m e s tic H ot W at er

prog ramme.

4. IN D IR E C T boile

r no t

w ork ing .

4. C h ec k boiler o peration. If fault is

s us pec ted c on s ult boiler m a nufac turer's

ins tru c t ions .

5. IN D IR E C T th erm al c ut-ou t

has op era ted.

5. C h ec k . R es et by pu s h in g b utto n on c u t-

out. Ch ec k ope ration o f in dire c t therm o s t at

(Figure 16, page 23 ).

6. IN D IR E C T m ot oris ed valve

not c onne c ted c o rrec tly .

6. C h ec k wiring and/o r p lum bing

c onnec tio ns to m oto ris ed valve (s ee F ig 13

and 14).

1. IN TE R M ITTE N TL Y

Air Volume in Megaflo eco

has reduced.

1. S ee Page 38 (Operational Faults

s e c tion for re-c harg ing )

2. C O NTINU A

LLY

2a. C hec k pres s ure from 3 Bar Presssure

Reducing Valve. If g reater than 3 b ar

replac e P re s s ure R ed uc er c artridge.

b. E x pan s ion V alve s eat

dam ag ed.

W ater d is c harges from the

T&P Relief valve continually

1. The rm a l c ontro l fa ilure

N O TE w ate r w ill b e very ho t.

1. S w itc h o ff pow e r to immers ion hea te r(s )

and s hut do wn b oiler. D O N O T tu rn o ff

w ate r s upply . W hen discha rge s tops

c heck a ll the rm a l c on trols , rep lac e if fa ulty .

M ilk y w ater

1. O x y ge nate d w ate r.

rele as es ox y gen bub bles wh en flow

ing. The

m ilk ine ss w ill dis appe ar after a s hort w hile .

No ho t w a ter flow

W ate r from hot ta ps is c old

W ater d is c harges from

8Bar Ex pans io n V a lve

1. C h ec k and o pen s top c oc k .

2. Turn o ff w a ter s upp ly . R em ove s tra ine r

1. W ate r from a pre s s uris e d s y s tem

2b. R em ove E x pans ion Relief c art rid ge from

8 Bar Pressure Relief valve and check seating. If

necessary fit new cartridge

a. 3 Bar Pressure Reducing

Valve not working correctly

1. Air volume in Megaflo eco has

reduced

1. S ee Page 38 (Operational Faults

s e c tion for re-c harg ing )

W ater d is c harges from the

T&P Relief valve intermittently

2. 8 Bar expansion relief valve

faulty

2. Check valve and replace if necessary

Loading...

Loading...