Chapter IV Dex PM3000 27

Full-Digital Control CO2/MAG/MIG Multi-FunctionWelding Machine

1. Enter into the internal function, and adjust the welder panel knob to F22.Press the "Fn" key, and the

right nixie tube flashes.

2. Turn the knob on the right panel to adjust the F22 parameters (shownin table 4-12), press the "Fn"key

to confirm, and F22 parameter setting is completed.

Table4-12Parameter Table of DC Chopping Time

Function Code Unit Adjusting Range Step Length Default Value

F22 s

0.00~1.00s

0.01s 0.24s

Fast Rising Slope of DC Welding Short-Circuit Current(F23)

The current rising speed changes during the short-circuit time underDC welding.

1. Enter into the internal function, and adjust the welder panel knob to F23.Press the "Fn" key, and

theright nixie tube flashes.

2. Turn the knob on the right panel to adjust the F23 parameters (shownin table 4-13), press the "Fn" key

to confirm, and F23 parameter setting is completed.

Table4- 3Parameter Table on Fast Rising Slope of DC Welding Short-Circuit Current

Function Code Unit Adjusting Range Step Length Default Value

F23 /

1~300

1 Automatic Matching

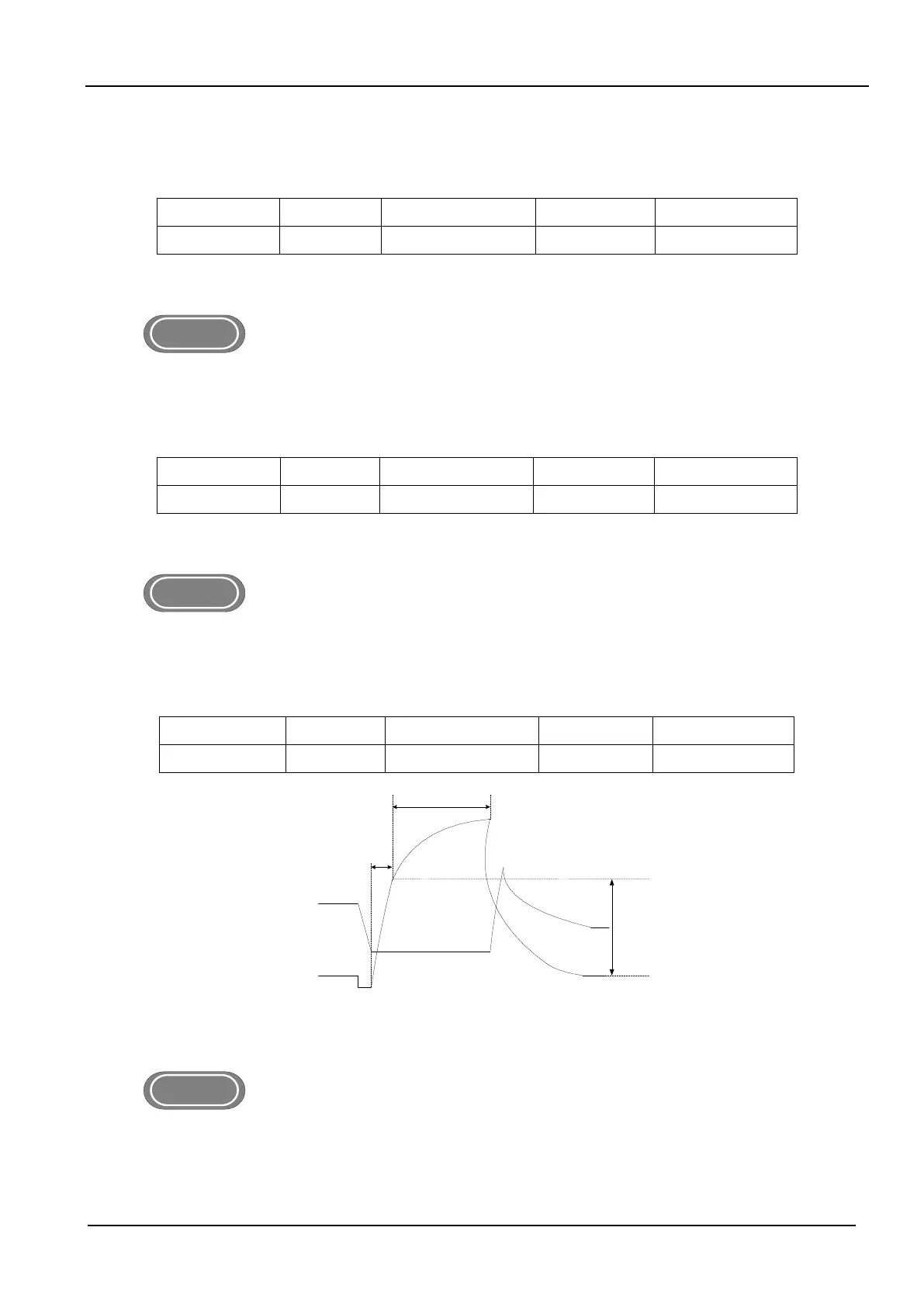

QuickRising Amplitude of DC Welding Short-Circuit Current(F24)

The current rising speed amplitude during the short-circuit time when conducting the DC welding.

1. Enter into the internal function, and adjust the welder panel knob to F24.Press the "Fn" key, and the

right nixie tube flashes.

2. Turn the knob on the right panel to adjust the F24 parameters (shownin table 4-14), press the "Fn" key

to confirm, and F24 parameter setting is completed.

Table4- 14 Parameter Table of Fast Rising Amplitude of DC Welding Short-Circuit Current

Function Code Unit Adjusting Range Step Length Default Value

F24 A

0~500A

1A AutomaticMatch

Voltage

Current

Slope

Amplitude

Arc Characteristic Slope

Fig.4-13 Fast Rising Slope and Amplitude of Current

DC Welding EnergyControl(F55)

1. Enter into the internal function, and adjust the welder panel knob to F55.Press the "Fn" key, and the

right nixie tube flashes.

2. Turn the knob on the right panel to adjust the F55 parameters (shownin table 4-15), press the "Fn" key

to confirm, and F55 parameter setting is completed.

Table4- 15 ParameterTable of DC Welding EnergyControl

Loading...

Loading...