MAINTENANCE

65

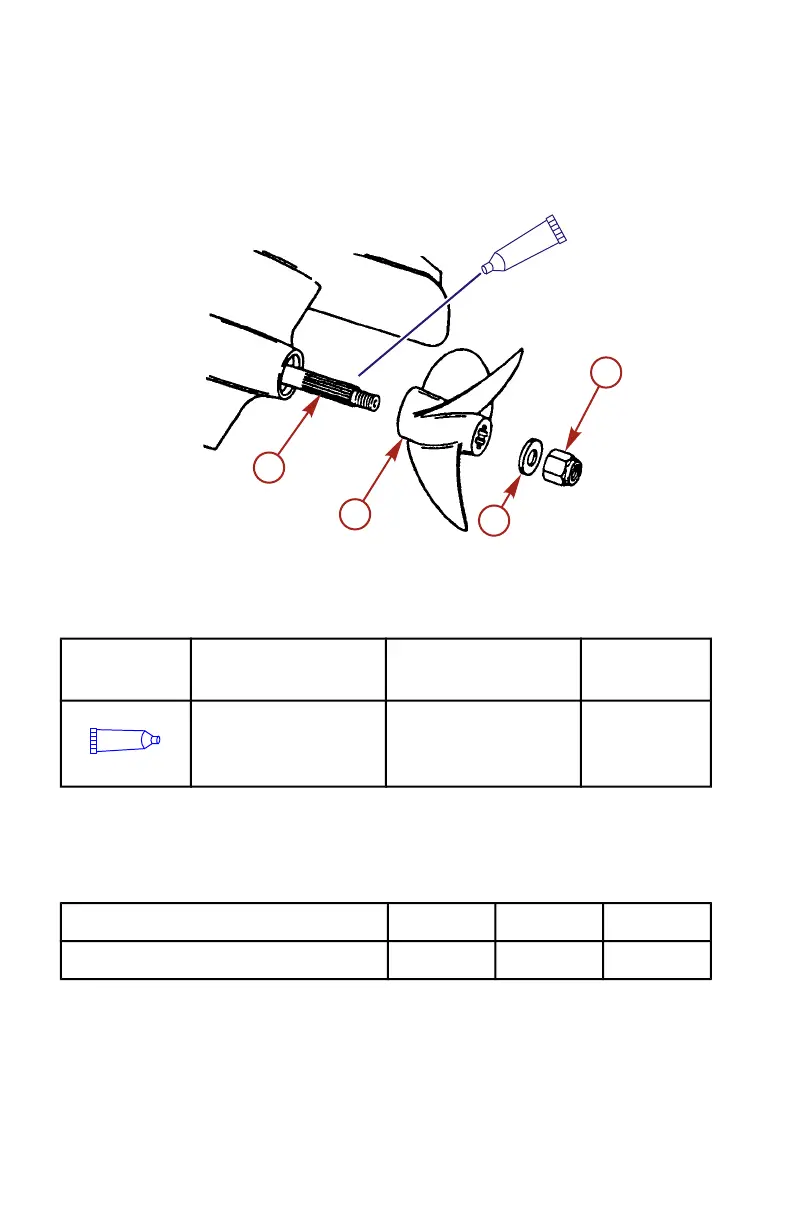

INSTALLATION

1. Apply a liberal coat of Optimal Longtime PD2 Extreme Pressure

Grease to propeller shaft.

2. Align splines and install propeller, washer and propeller nut.

a - Propshaft

b - Cleaver propeller

c - Flat washer

d - Propeller nut

Tube Ref.

No.

Description Where Used Part No.

Optimal Longtime

PD2 Extreme

Pressure Grease

Propeller shaft

splines

92‑848767

3. Place wood block between the propeller blade and anti‑ventilation plate

to prevent rotation and tighten the propeller nut. After first use,

re‑tighten propeller nut. Check propeller at least every 20 hours of

operation. Do not operate with a loose propeller.

Description Nm lb. in. lb. ft.

Propeller nut 136 100

Seawater Pump Impeller Inspection

Seawater Pump Impeller service should be performed by an authorized

Mercury Marine dealer.

Loading...

Loading...