90-10100R30

15

GB

goh7

1–3

a

b

oh

MAINTENANCE

ohq1

GEAR CASE LUBRICATION

When adding or changing gear case lubricant, visually check for the presence of

water in the lubricant. If water is present, it may have settled to the bottom and will

drain out prior to the lubricant, or it may be mixed with the lubricant, giving it a milky

colored appearance. If water is noticed, have the gear case checked by your

dealer.Water in the lubricant may result in premature bearing failure or, in freezing

temperatures, will turn to ice and damage the gear case.

Also examine the gear case lubricant for metal particles. A small amount of metal

filings or fine metal particles indicates normal gear wear. An excessive amount of

metal filings or larger particles (chips) may indicate abnormal gear wear and

should be checked by an authorized dealer.

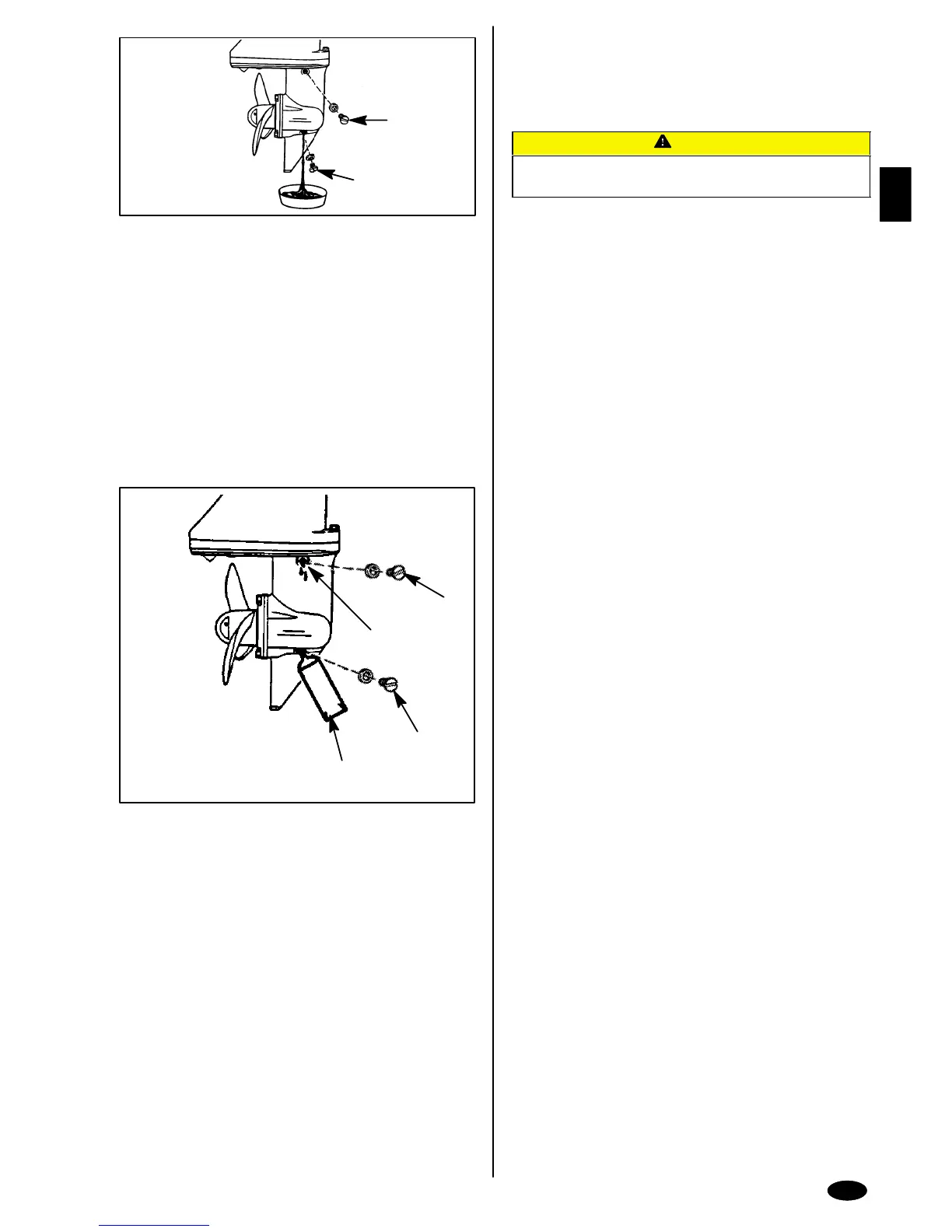

Draining Gear Case

1 Place outboard in a vertical operating position.

2 Place drain pan below outboard.

3 Remove fill/drain plug (a) and vent plug (b) and drain lubricant.

ohv1

Gear Case Lubricant Capacity

Gear case lubricant capacity is approximately 4.5 fl. oz. (135ml).

goh8

1-5

a

c

b

d

ohw1

GEAR CASE LUBRICATION (CONTINUED)

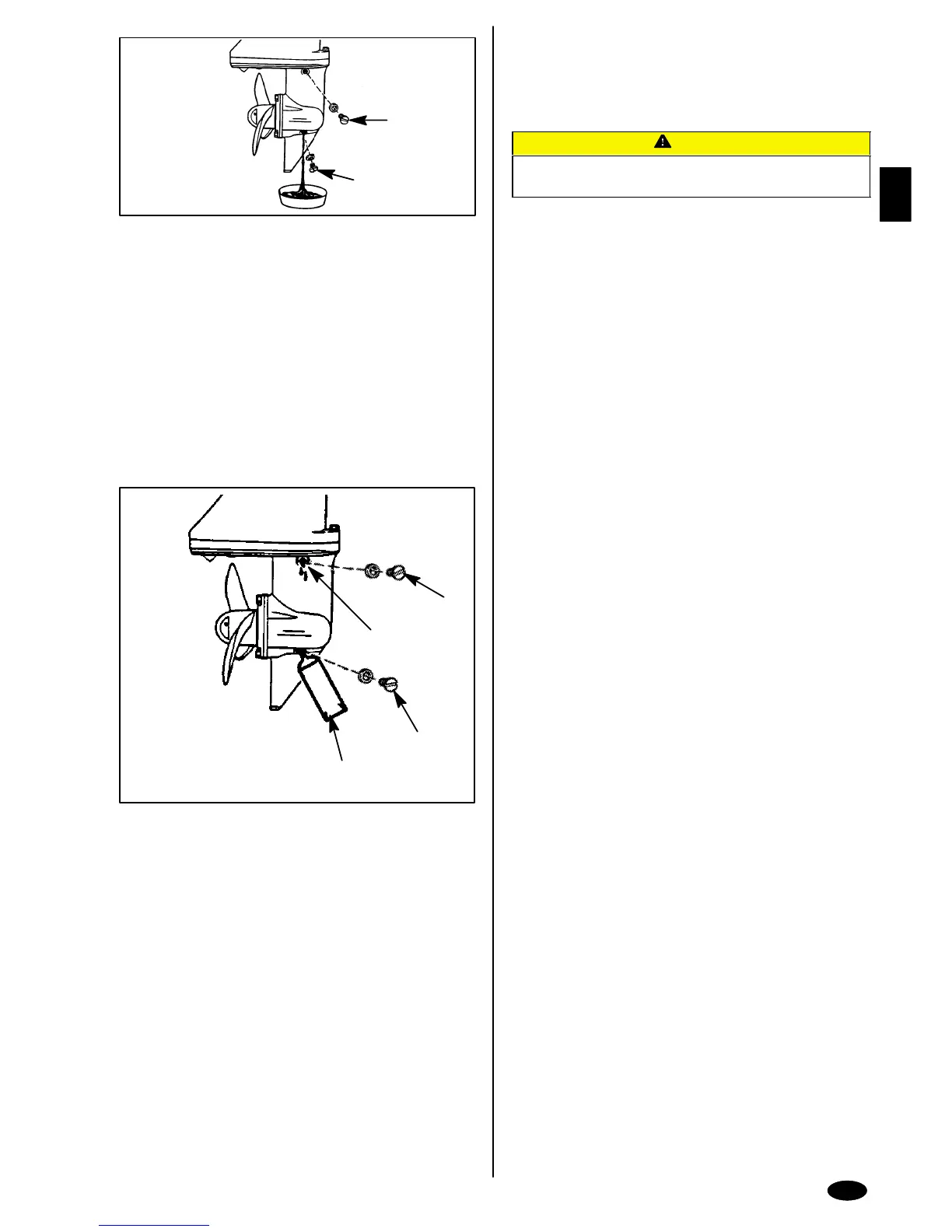

Checking Lubricant Level and Refilling Gear case

1 Place outboard in a vertical operating position.

2 Remove vent plug and sealing washer (a).

3 Place lubricant tube (b) into the fill hole and add lubricant until it appears at the

vent hole (c).

4 Stop adding lubricant. Install the vent plug and sealing washer (a) before

removing the lubricant tube.

5 Remove lubricant tube and reinstall cleaned fill/drain plug and sealing washer

(d).

ohr1

SUBMERGED OUTBOARD

A submerged outboard will require service within a few hours by an authorized

dealer once the outboard is recovered from the water. This immediate attention by

a servicing dealer is necessary once the engine is exposed to the atmosphere to

minimize internal corrosion damage to the engine.

oi

STORAGE

oia1

STORAGE PREPARATION

The major consideration in preparing your outboard for storage is to protect it from

rust, corrosion, and damage caused by freezing of trapped water.

The following storage procedures should be followed to prepare your outboard for

out-of-season storage or prolonged storage (two months or longer).

CAUTION

Never start or run your outboard (even momentarily) without water

circulating through the cooling water intake in the gear case to prevent

damage to the water pump (running dry) or overheating of the engine.

oib12

Fuel system

IMPORTANT: Gasoline containing alcohol (ethanol or methanol) can cause

a formation of acid during storage and can damage the fuel system. If the

gasoline being use contains alcohol, it is advisable to drain as much of the

remaining gasoline as possible from the fuel tank and engine fuel system.

Fill the fuel system (tank, hoses, and carburetor) with treated (stabilized) fuel to

help prevent formation of varnish and gum. Proceed with following instructions.

1. Pour the required amount of Gasoline Stabilizer (follow instructions on

container) into fuel tank. Tip fuel tank back and forth to mix stabilizer with the

fuel.

2. Place the outboard in water. Run the engine for five minutes to allow treated

fuel to reach the carburetor.

oic4

Protecting External Outboard Components

3. Lubricate all outboard components listed in the Inspection and Maintenance

Schedule.

4. Touch up any paint nicks. See your dealer for touch-up paint.

5. Spray Quicksilver or Mercury Precision Lubricantions Corrosion Guard on

external metal surfaces (except corrosion control anodes).

oid13

Protecting Internal Engine Components

Note: Before performing Steps 6 and 7, make sure the fuel system has been

prepared for storage. Refer to Fuel System on previous page.

6. Place the outboard in water. Start the engine and let it run in neutral to warm

up.

7. With engine running at fast idle, stop the fuel flow by closing the fuel shut-off

valve. When engine begins to stall, quickly spray Quicksilver or Mercury

Precision Lubricants Storage Seal into carburetor until engine stops from lack

of fuel.

8. Remove the spark plug and inject a five second spray of Storage Seal around

the inside of the cylinder.

9. Rotate the flywheel manually several times to distribute the storage seal in the

cylinder. Reinstall spark plug.

oie1

Gear Case

10.Drain and refill the gear case lubricant (refer to maintenance procedure).

oif1

Positioning Outboard for Storage

Store outboard in an upright position to allow water to drain out of outboard.

Loading...

Loading...