Section 4 - Maintenance

Page 32 90-8M0113857 eng DECEMBER 2015

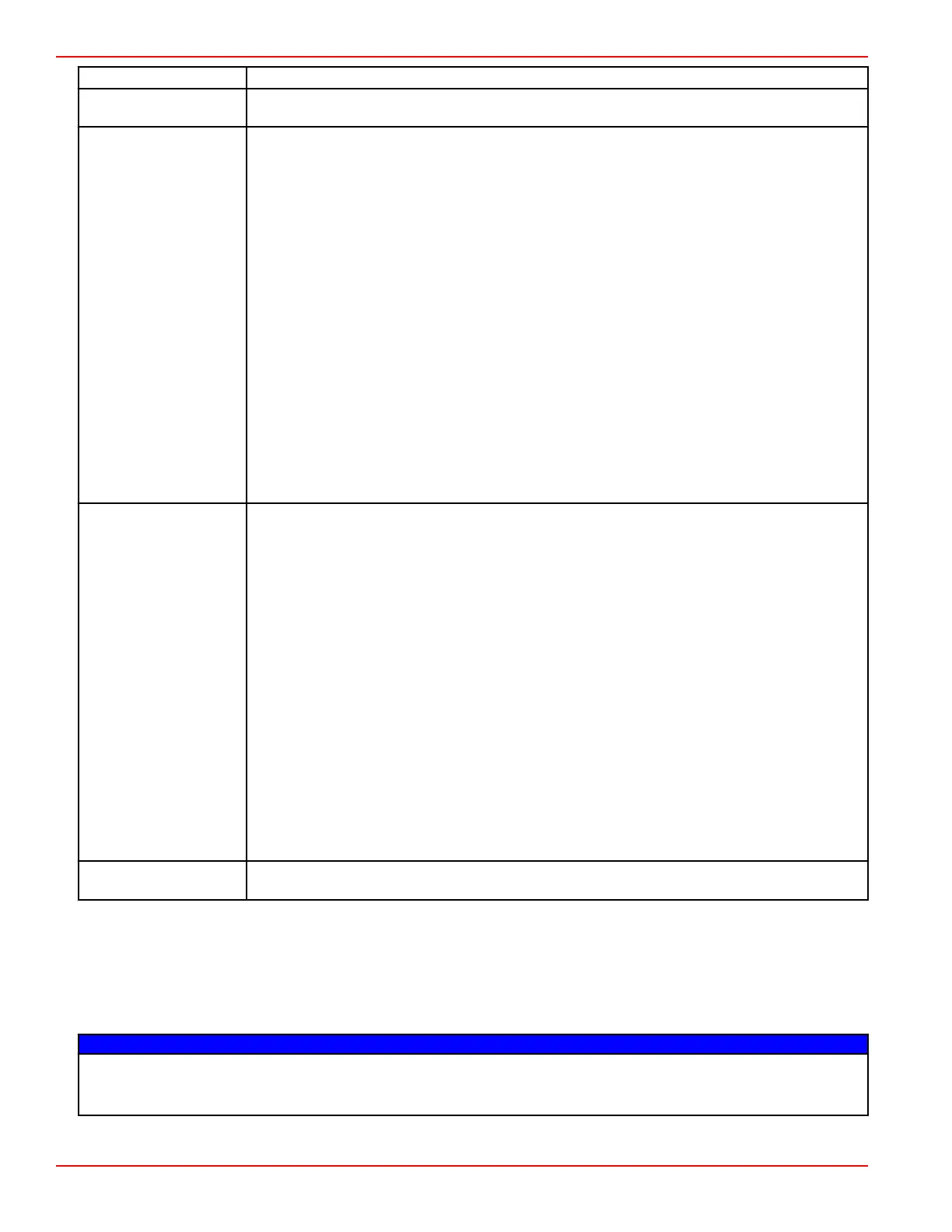

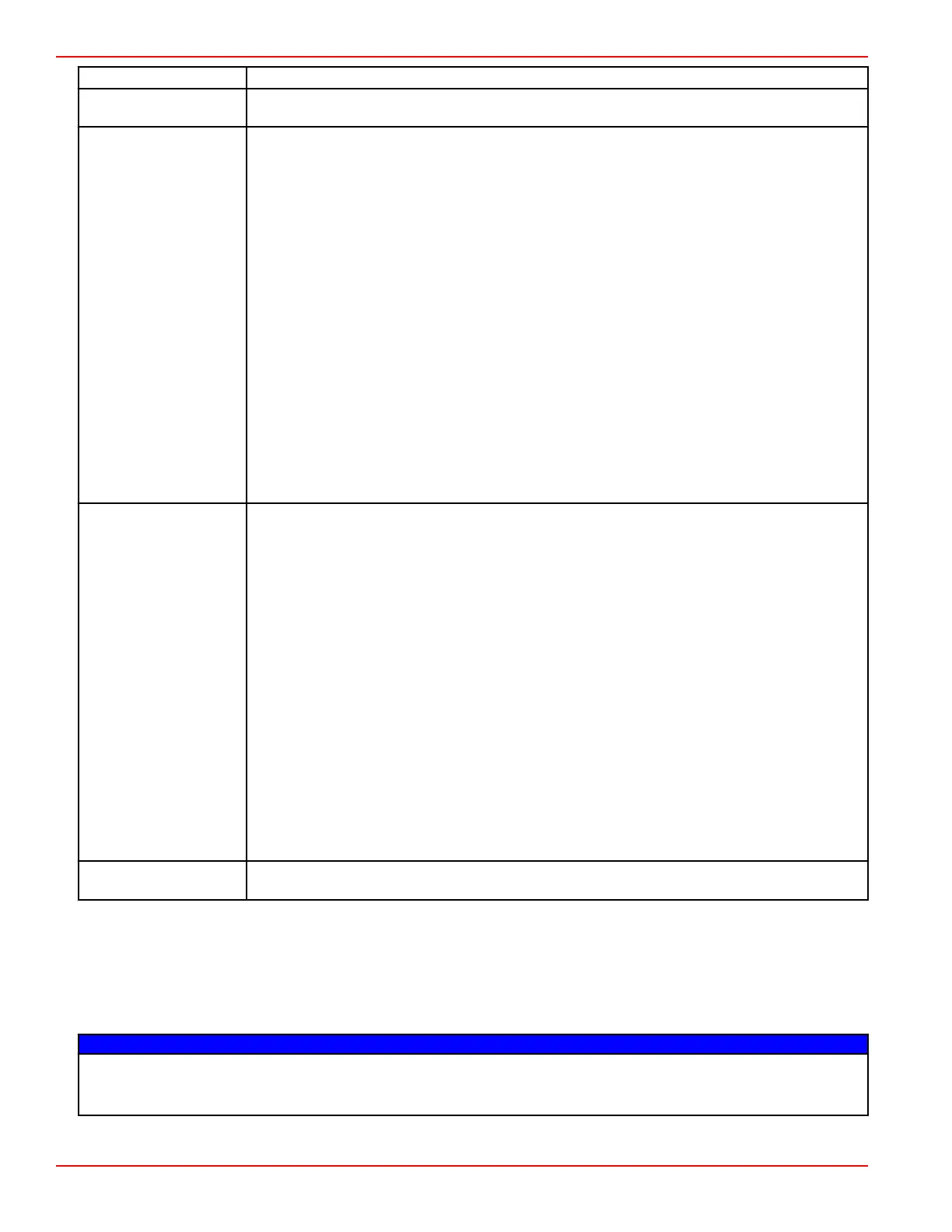

Task Interval Maintenance to Be Performed

After the initial 20‑hour

break‑in period

Change the engine oil and filter.

Every 100 hours or

annually

(whichever occurs first)

• Touch‑up the paint on the power package.

• Change the engine oil and filter.

• Change the sterndrive gear lube.

• If the condition of the spark plugs, spark plug wires, and the distributor cap and rotor was

satisfactory at the initial inspection (as listed in Every 300 hours or 3 years), inspect the

condition of these components. Replace as necessary.

• On models with closed cooling, check the coolant level and antifreeze concentration for

adequate freeze protection. Correct if necessary. Refer to the Specifications section.

• Tighten the connection of the gimbal ring to the steering shaft to specifications.

• Replace the water‑separating fuel filter.

• Check the steering system and the remote control for loose, missing, or damaged parts.

Lubricate the cables and the linkages.

• Check the continuity circuit for loose or damaged connections. Test the MerCathode unit

output if equipped.

• Clean the flame arrestor, IAC muffler, and the crankcase ventilation hoses. Inspect the PCV

valve, if equipped.

• Inspect the condition and the tension of the belts.

• Driveshaft extension models: Lubricate the driveshaft U‑joints, and tailstock input and output

bearings.

Every 300 hours or 3

years

• Check the engine mounts for tightness and torque if necessary.

• Check the electrical system for loose, damaged, or corroded fasteners.

• Inspect the condition of the spark plugs, spark plug wires, and the distributor cap and rotor, if

equipped. Replace as necessary. If the condition of these components is satisfactory at

inspection, repeat inspection every 100 hours or once a year, whichever occurs first.

• Check the cooling system and the exhaust system hose clamps for tightness. Inspect both

systems for damage or leaks.

• Disassemble and inspect the seawater pump and replace worn components.

• On models with closed cooling, clean the seawater section of the closed cooling system.

Clean, inspect, and test the pressure cap.

• Inspect the exhaust system components. If the package was equipped with water shutters

(flapper valves), verify that they are not missing or worn.

• Check the engine alignment.

• Inspect the U‑joints, the splines, the bellows, and check the clamps.

• Lubricate the U‑joint splines and cross bearing, if equipped with a grease fitting.

• Inspect the gimbal bearing for roughness. Replace if necessary. See your certified Mercury

MerCruiser dealer.

• Lubricate the engine coupler.

Every 5 years

• Replace the coolant/antifreeze. Replace every two years if not using extended‑life coolant/

antifreeze.

Sealed Carburetor Mixture Screw

IMPORTANT: Changing the mixture setting on this engine can affect the exhaust emissions level and void the emissions

certification. Do not adjust or remove the mixture settings or remove the mixture screw seals. See your authorized Mercury

dealer or emissions testing agency.

Engine Oil

NOTICE

Discharge of oil, coolant, or other engine/drive fluids into the environment is restricted by law. Use caution not to spill oil,

coolant, or other fluids into the environment when using or servicing your boat. Be aware of the local restrictions governing

the disposal or recycling of waste, and contain and dispose of fluids as required.

Loading...

Loading...