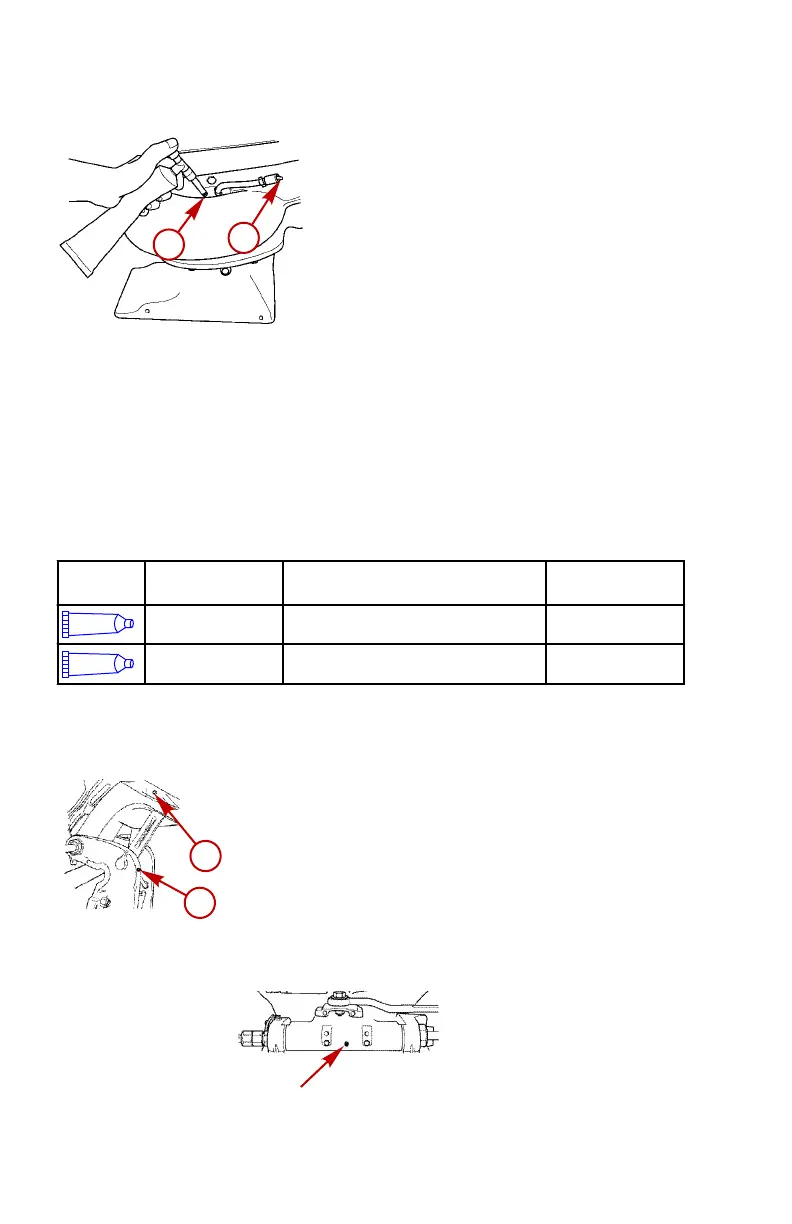

iii. Reconnect the vent hose onto the grease fitting after greasing.

a - Grease fitting

b - Vent hose

NOTE: After 30 hours of operation, pump in extra grease to purge out any

moisture. Visually inspecting the purged grease at this time will give an

indication of conditions inside the bearing housing. A gradual increase in

moisture content indicates seal wear. If the grease begins to turn a dark, dirty

gray color, the driveshaft bearing and seals should be inspected and replaced

if necessary. Some discoloration of the grease is normal during the break‑in

period on a new set of seals.

2. Lubricate the following with Quicksilver or Mercury Precision Lubricants

2‑4‑C with PTFE or Extreme Grease.

Tube Ref

No.

Description Where Used Part No.

Extreme Grease

Swivel bracket, tilt support lever, tilt

tube, steering cable grease fitting

8M0071842

95

2-4-C with PTFE

Swivel bracket, tilt support lever, tilt

tube, steering cable grease fitting

92-802859A 1

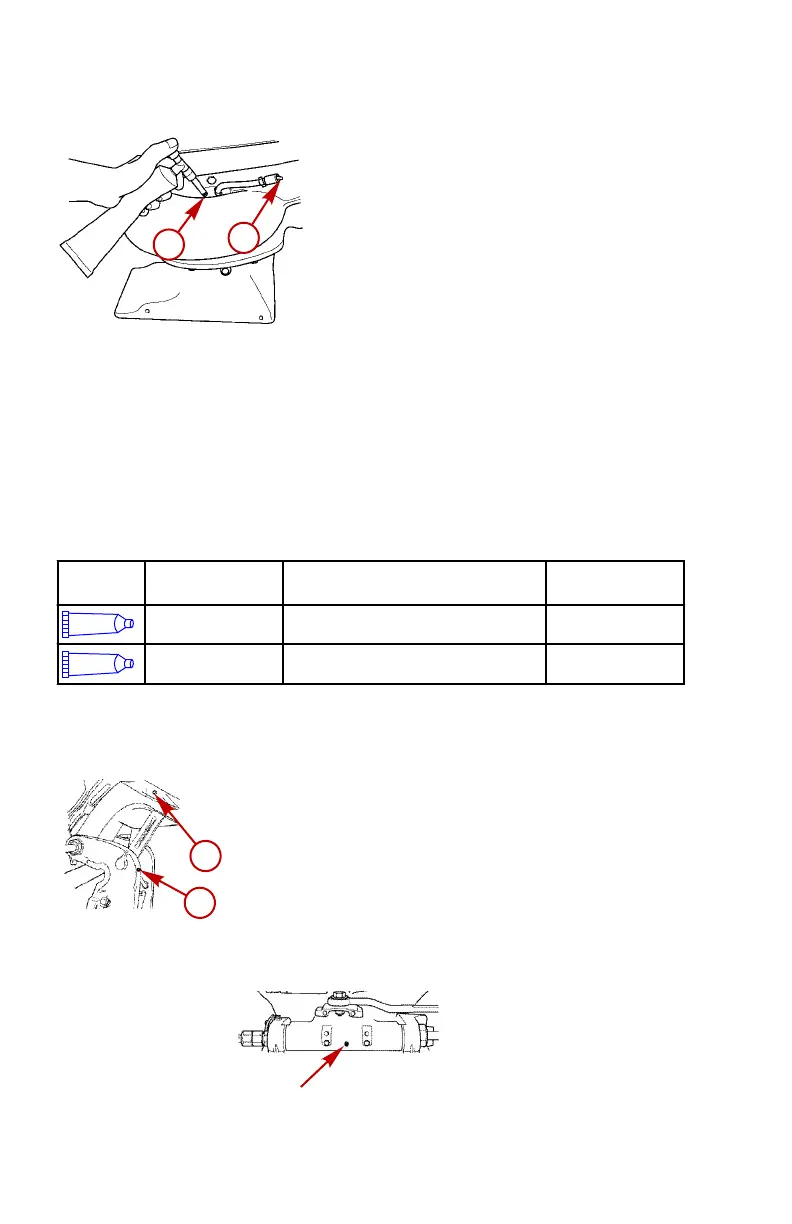

• Swivel bracket ‑ Lubricate through fitting.

• Tilt support lever ‑ Lubricate through fitting.

a - Swivel bracket

b - Tilt support lever

• Tilt tube ‑ Lubricate through fitting.

MAINTENANCE

98 eng

Loading...

Loading...